Production process of barium carbonate

A production process, barium carbonate technology, applied in the direction of barium carbonate, calcium carbonate/strontium/barium, etc., can solve the problems of large amount of dispersant, small specific surface area, complex production process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

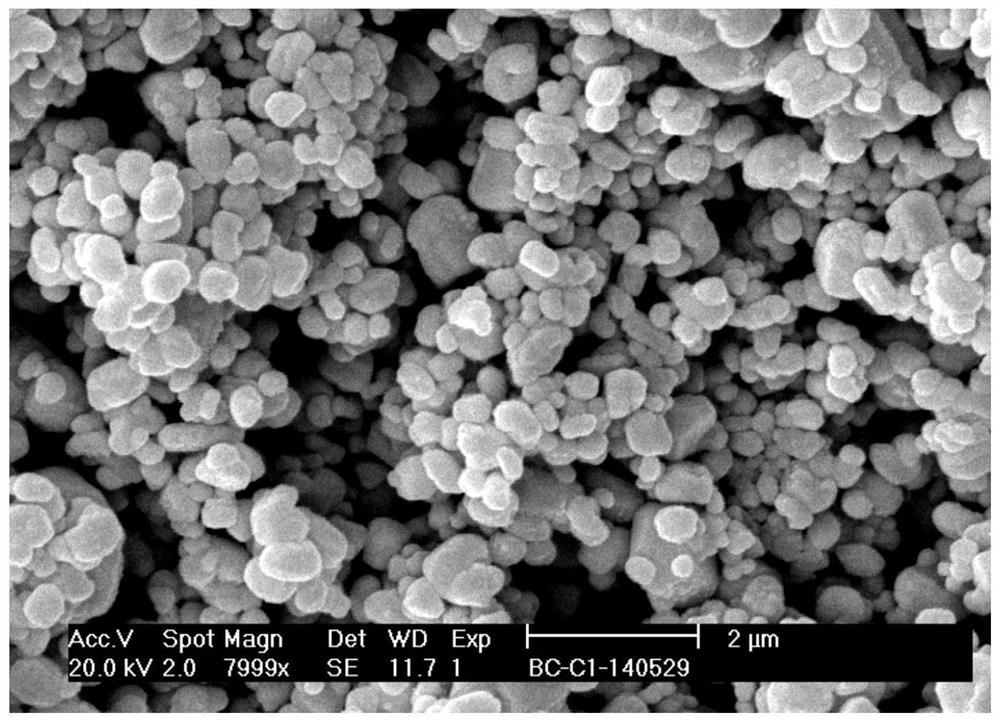

Image

Examples

Embodiment 1

[0027] A kind of production technology of barium carbonate, described method comprises the following steps:

[0028] S1: Add barium hydroxide to high-purity water, place it in a dissolving pump for dissolution, and obtain a barium hydroxide solution;

[0029] S2: Add liquid ammonia to the barium hydroxide solution prepared in step S1, and stir at a constant temperature for 10-60 min at 40° C.;

[0030] S3: Pass carbon dioxide into the barium hydroxide solution that is added with liquefied ammonia described in step S2 through a micro-reaction device under stirring state, stop passing carbon dioxide when pH=6, obtain barium carbonate solution;

[0031] S4: heating the barium carbonate solution prepared in step S3 to make it fully react; then carry out precipitation and filtration to obtain barium carbonate precipitate;

[0032] S5: drying the barium carbonate precipitate in step S4 in a desiccator to obtain high-purity electronic grade barium carbonate.

[0033] Preferably, th...

Embodiment 2

[0044] A kind of production technology of barium carbonate, described method comprises the following steps:

[0045] S1: Add barium hydroxide to high-purity water, place it in a dissolving pump for dissolution, and obtain a barium hydroxide solution;

[0046] S2: Add liquid ammonia to the barium hydroxide solution prepared in step S1, and stir at a constant temperature for 30 minutes at 30° C.;

[0047] S3: Pass carbon dioxide into the barium hydroxide solution that is added with liquefied ammonia described in step S2 through the micro reaction device under stirring state, stop passing carbon dioxide when pH=7, obtain barium carbonate solution;

[0048] S4: heating the barium carbonate solution prepared in step S3 to make it fully react; then carry out precipitation and filtration to obtain barium carbonate precipitate;

[0049] S5: drying the barium carbonate precipitate in step S4 in a desiccator to obtain high-purity electronic grade barium carbonate.

[0050] Preferably,...

Embodiment 3

[0061] A kind of production technology of barium carbonate, described method comprises the following steps:

[0062] S1: Add barium hydroxide to high-purity water, place it in a dissolving pump for dissolution, and obtain a barium hydroxide solution;

[0063] S2: Add liquid ammonia to the barium hydroxide solution prepared in step S1, and stir at a constant temperature of 45° C. for 46 minutes;

[0064] S3: Pass carbon dioxide into the barium hydroxide solution that is added with liquefied ammonia described in step S2 through a micro-reaction device under stirring state, stop passing carbon dioxide when pH=7.5, obtain barium carbonate solution;

[0065] S4: heating the barium carbonate solution prepared in step S3 to make it fully react; then carry out precipitation and filtration to obtain barium carbonate precipitate;

[0066] S5: drying the barium carbonate precipitate in step S4 in a desiccator to obtain high-purity electronic grade barium carbonate.

[0067] Preferably,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com