Stone adhesive and preparation method thereof

A technology for adhesives and stone materials, applied in the direction of adhesives, adhesive types, polymer adhesive additives, etc., can solve the problems of poor temperature adaptability, high VOC content, etc., achieve good toughness, good color fullness, and improve The effect of temperature adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

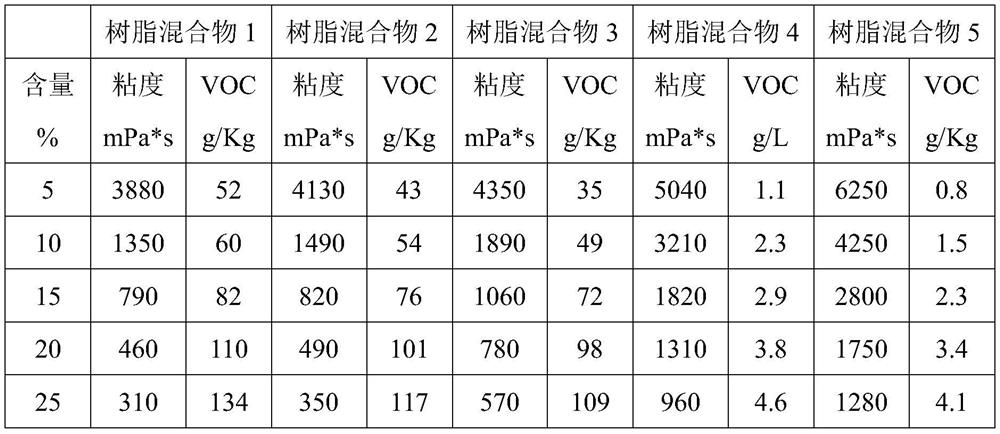

[0070] A kind of stone adhesive of the present invention is prepared from following components and preparation method:

[0071] (1) Preparation of component A: Mix 28 parts of bisphenol A epoxy resin, 7 parts of novolac epoxy, and 5 parts of epoxy soybean oil for 10 minutes to mix evenly, add 1 part of nano-calcium to mix and then pass through a three-roller machine Grind and disperse once, then add 5 parts of 200-mesh red colored sand and 54 parts of calcite powder, stir at -0.06MPa for 20 minutes and discharge to obtain component A;

[0072] (2) Preparation of component B:

[0073] (1) Preparation of modified curing agent: put 3 mol of toluene diisocyanate in a container, heat up to 60°C, add 1 mol of polyethylene glycol PEG400 dropwise, complete the dropwise addition within 1 hour, keep at 60°C for 2 hours, and then discharge to obtain modified Reactive agent isocyanate terminated polyether polyol. Then put 2.5mol of triethylenetetramine in the container, raise the temper...

Embodiment 2

[0077] A kind of stone adhesive of the present invention is prepared from following components and preparation method:

[0078] (1) Preparation of component A: Mix 22 parts of bisphenol F-type epoxy resin and 33 parts of novolac epoxy with 25 parts of epoxy linseed oil for 15 minutes to mix evenly, add 5 parts of polyamide wax and mix through three Grind and disperse with a roller machine for 3 times, then add 10 parts of 400-mesh red colored sand and 5 parts of silicon micropowder, stir at -0.1MPa for 40 minutes and discharge to obtain component A;

[0079] (2) Preparation of component B:

[0080] (1) Preparation of modified curing agent: put 5 mol of hydrogenated phenylmethane diisocyanate in a container, raise the temperature to 80°C, add 1 mol of polyethylene glycol PEG600 dropwise, complete the dropwise addition within 3 hours, keep at 80°C for 4 hours, and leave isocyanate-terminated polyether polyols. Then put 4 mol of hydrogenated m-xylylenediamine in the container, ...

Embodiment 3

[0084] A kind of stone adhesive of the present invention is prepared from following components and preparation method:

[0085] (1) Preparation of component A: mix 20 parts of bisphenol A type epoxy resin, 8 parts of bisphenol F type epoxy resin, and 12 parts of novolac epoxy with 8 parts of epoxy cottonseed oil and 2 parts of epoxy oil Stir the butyl ester for 12 minutes to mix evenly, add 2 parts of organic bentonite to mix, then grind and disperse twice through a three-roller machine, then add 6 parts of 300 mesh red colored sand and 42 parts of barite powder, and stir for 30 minutes under vacuum at -0.07MPa. material, to obtain A component;

[0086] (2) Preparation of component B:

[0087] (1) Preparation of modified curing agent: put 4 mol of methylcyclohexyl diisocyanate in a container, heat up to 70°C, add 1 mol of polypropylene glycol PPG400 dropwise, complete the dropwise addition within 2 hours, keep at 70°C for 3 hours, and discharge to obtain isocyanate End-cappe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com