RGO-coated Pd7Se2 composite structure nano material as well as preparation method and application thereof

A technology of composite structures and nanomaterials, applied in electrodes, electrolytic processes, electrolytic components, etc., can solve the problems of electron transfer, optimization, and unfavorable nitrogen fixation performance in the interior and interface of unhelpful materials, achieve continuous electrolytic stability, and promote electron transfer , Excellent catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A kind of rGO@Pd 7 Se 2 A method for preparing a composite structure nanomaterial, comprising the following steps:

[0029] Step 1: Disperse 10mg of graphene oxide (GO) in 15ml of deionized water and stir evenly;

[0030] Step 2: Add 0.05mmol selenous acid, 0.1mmol sodium tetrachloropalladate, 0.1mmol sodium citrate, 0.2mmol sodium hydroxide and 0.1mmol sodium borohydride to the solution obtained in step 1, mix and stir evenly until the color of the solution changes Stop stirring when it is black;

[0031] Step 3: transfer the mixed solution obtained in step 2 to a reaction kettle, and conduct a hydrothermal reaction at 200° C. for 5 hours;

[0032] Step 4: After the reaction, cool down to room temperature naturally, then filter the solution to obtain gray-black precipitate, wash and freeze-dry to obtain rGO@Pd 7 Se 2 Nanoparticle composite structure.

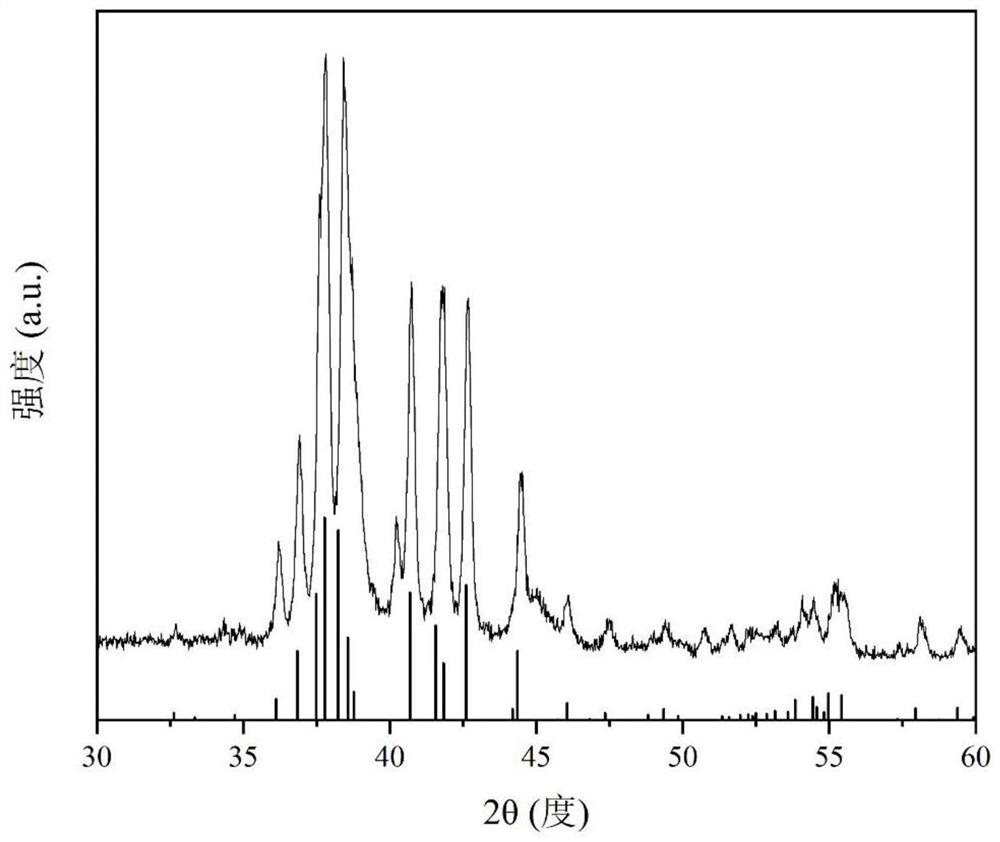

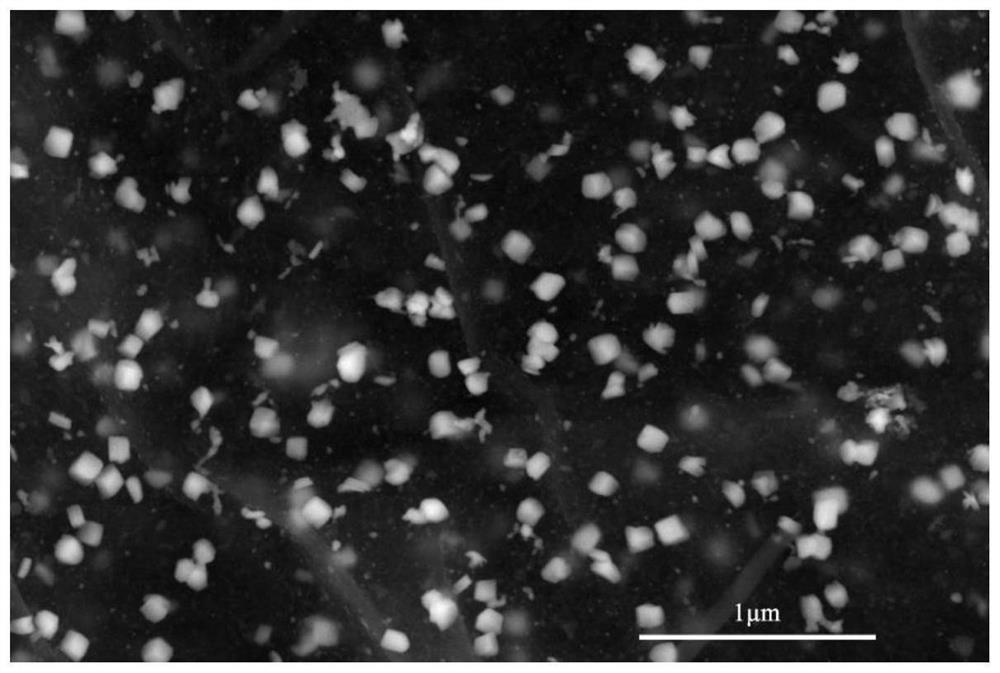

[0033] The rGO@Pd that embodiment 1 obtains 7 Se 2 X-ray diffraction (XRD) pattern of composite structure nano...

Embodiment 2

[0036] A kind of rGO@Pd 7 Se 2 A method for preparing a composite structure nanomaterial, comprising the following steps:

[0037] Step 1: Disperse 10 mg of graphene oxide (GO) in 15 ml of deionized water, and stir evenly, and stop stirring when the color of the solution turns black;

[0038] Step 2: Add 0.05mmol of selenous acid, 0.1mmol of sodium tetrachloropalladate, 0.1mmol of sodium citrate, 0.2mmol of sodium hydroxide and 0.1mmol of sodium borohydride to the solution obtained in step 1, and mix and stir evenly;

[0039] Step 3: transfer the mixed solution obtained in step 2 to a reaction kettle, and conduct a hydrothermal reaction at 300° C. for 6 hours;

[0040] Step 4: After the reaction, cool down to room temperature naturally, then filter the solution to obtain gray-black precipitate, wash and freeze-dry to obtain rGO@Pd 7 Se 2 Nanoparticle composite structure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com