Amide-modified polyester resin for powder coating and powder coating

A technology for amide-modified polyester and powder coatings, which is applied in the field of amide-modified polyester resins for powder coatings and powder coatings, and can solve the problems of easy occurrence of pinholes in coating films, poor leveling effect of powder coatings, and high functionality of curing agents and other problems, to achieve the effect of reducing the difficulty of treatment, reducing the cost of treatment, and the difficulty of waste treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

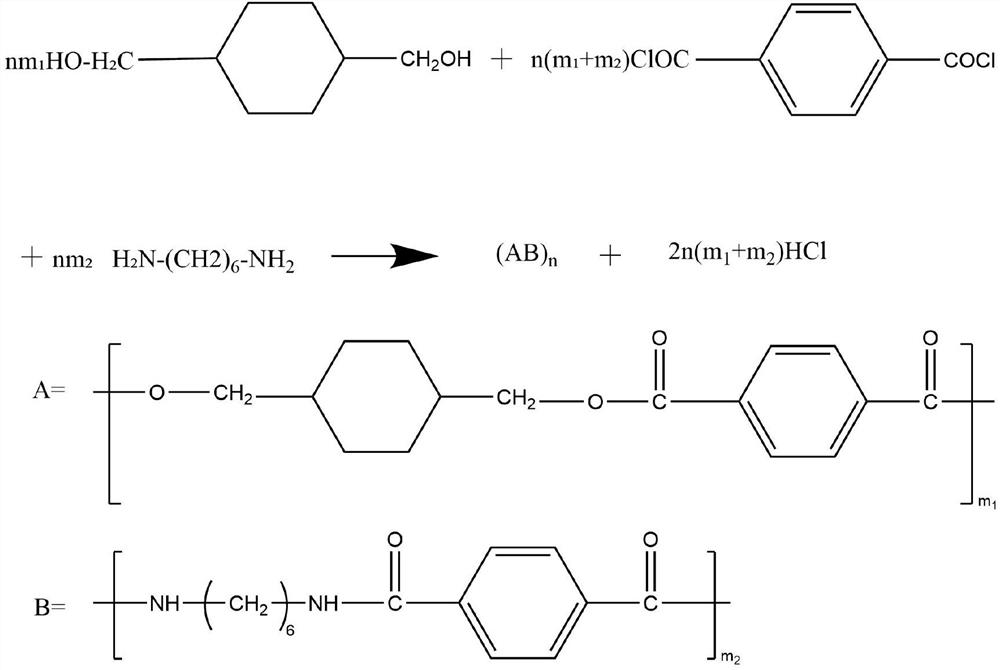

Image

Examples

Embodiment 1~4

[0035] This example is used to illustrate the amide-modified polyester resin for powder coating provided by the present invention and its preparation method.

[0036] Amide-modified polyester resin for powder coatings, according to mass percentage, includes the following components: 35% to 40% polyol, 50% to 53% polyacid, 0.6% to 3.1% polybasic anhydride, 0.4% to 2% polyamine , 0.04%-1% esterification catalyst, 8%-15% first acidolysis agent, 0.2%-1% antioxidant, 0.03%-0.05% curing accelerator.

[0037] Its preparation method comprises the following steps:

[0038] Step S1: Dissolve hexahydrophthalic anhydride and 4,4-diaminodiphenylmethane with a mass ratio of 1.56:1 in acetone solution, and slowly add the acetone solution of 4,4-diaminodiphenylmethane dropwise under stirring To the acetone solution of hexahydrophthalic anhydride, a white precipitate precipitated during the dropwise addition. After the dropwise addition was completed, cool at 5°C for 1 hour, filter, and retai...

Embodiment 5~8

[0065] This example is used to illustrate the application of the amide-modified polyester resin provided by the present invention in powder coatings.

[0066] Powder coating, its raw material comprises amide modified polyester resin prepared in 56.4% embodiment 1~4, 3.6% β hydroxyalkylamide, 1% leveling agent, 0.4% benzoin, 25% titanium dioxide, 13.6% precipitated sulfuric acid barium, and the polyester resin is the amide-modified polyester resin described in any one of claims 1-9.

[0067] Preparation of powder coatings: a. Weigh and mix the amide-modified polyester resin, β hydroxyalkylamide, titanium dioxide, precipitated barium sulfate, leveling agent and benzoin prepared in Examples 1 to 4; b. The premixed mixture is melted and extruded through an extruder; c, cooled and pressed into tablets; d, the flakes are crushed in a coffee mill and sieved through a sieve to obtain a powder coating with a certain particle size distribution, which is bagged for later use.

[0068] E...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com