Preparation method of m-phenoxy benzaldehyde

A technology of m-phenoxybenzaldehyde and halobenzene is applied in the field of preparation of m-phenoxybenzaldehyde, can solve problems such as low yield and low purity of m-phenoxybenzaldehyde, and achieves reduction of production cost and simple process The effect of easy operation and cheap and easy to obtain raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

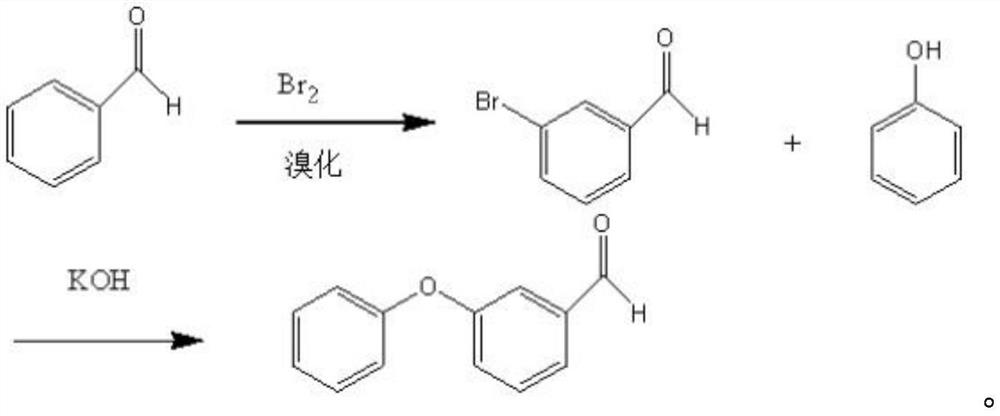

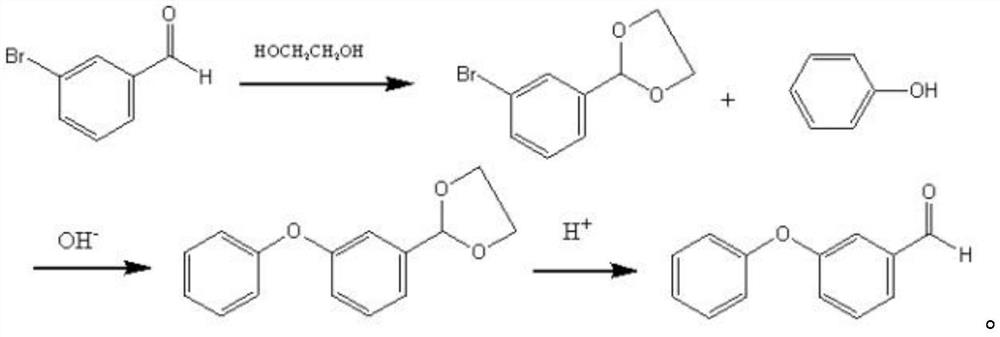

Method used

Image

Examples

preparation example Construction

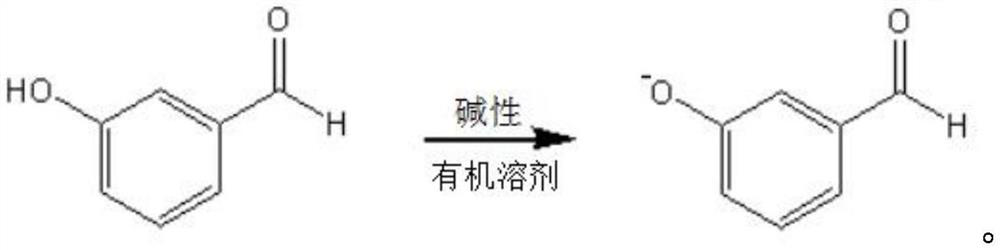

[0026] The invention provides a kind of preparation method of m-phenoxybenzaldehyde, comprising the following steps:

[0027] Performing a salt-forming reaction between m-hydroxybenzaldehyde and an alkaline reagent in an anhydrous organic solvent to obtain a salt-forming product reaction solution;

[0028] mixing the salt-forming product reaction liquid with halobenzene, performing a substitution reaction between the salt-forming product and halobenzene under alkaline conditions, and subjecting the obtained substitution reaction liquid to solid-liquid separation to obtain a liquid phase;

[0029] Fractional distillation is performed on the liquid phase, and fractions at 170-190° C. are collected to obtain the m-phenoxybenzaldehyde.

[0030] In the present invention, unless otherwise specified, the components in the preparation method are commercially available products well known to those skilled in the art.

[0031] In the invention, m-hydroxybenzaldehyde and alkaline reagen...

Embodiment 1

[0056] Mix 122.1g (1.0mol) of m-hydroxybenzaldehyde, 244mL of N,N-dimethylformamide and 165.8g (1.2mol) of anhydrous potassium carbonate, and control the pH value of the resulting mixed system to 12. Under heat preservation and stirring for 1h, carry out a salt-forming reaction to obtain a mixture containing an intermediate;

[0057] Under the condition of 90-100°C, 164.8g (1.05mol) of bromobenzene was added dropwise into the mixture at a rate of 2 drops / s, and the intermediate and halobenzene were kept and stirred at 90-100°C for 2 hours to carry out the substitution reaction. After the mixed system was cooled to 30°C, it was filtered, and the obtained filtrate was subjected to fractional distillation, and the fraction at 170-190°C was collected to obtain 160.5 g of m-phenoxybenzaldehyde.

[0058] The product obtained in this example is detected: mass spectrometry MS (ESI), m / z: 199.3 [M+H] + ;

[0059] NMR 1 H NMR (400MHz, CDCl 3 ), δ=7.22(2H, ArH), 6.98(H, ArH), 6.92(2H...

Embodiment 2

[0062] Mix 122.1g (1.0mol) of m-hydroxybenzaldehyde, 244mL of N-methylpyrrolidone and 165.8g (1.2mol) of anhydrous potassium carbonate, control the pH value of the resulting mixed system to 12, and keep stirring at 90-100°C for 1h Perform a salt-forming reaction to obtain a mixture containing intermediates;

[0063] Under the condition of 90-100°C, 164.8g (1.05mol) of bromobenzene was added dropwise into the mixture at a rate of 2 drops / s, and the intermediate and halobenzene were kept and stirred at 90-100°C for 2 hours to carry out the substitution reaction. After the mixed system was cooled to 30°C, it was filtered, and the resulting filtrate was subjected to fractional distillation, and the fraction at 170-190°C was collected to obtain 159.2 g of m-phenoxybenzaldehyde.

[0064] The present embodiment middle phenoxybenzaldehyde yield is 80.4%; The gas phase content GC of m-phenoxybenzaldehyde is 99.3%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com