Etching solution for low-resistance silicon product and etching method thereof

An etching solution and low-resistance technology, applied in chemical instruments and methods, circuits, electrical components, etc., can solve problems such as great impact on human health, large environmental pollution, and easy generation of bubbles, and achieve uniform and non-violent reactions and reduce risks. The effect of resistance and small amount of etching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] An etchant for low-resistance silicon products, by mass percentage, consists of the following substances:

[0036]

[0037] Solution preparation method: Weigh the required ammonium bifluoride according to the proportion, add an appropriate amount of water to dissolve, then slowly add potassium nitrate, phosphoric acid, sulfuric acid and ammonium persulfate according to the amount, stir evenly, cool to room temperature, and add octylphenol Polyoxyethylene ether and polyethylene glycol, plus the balance of water to volume. It is preferable to use ultrapure water of 18MΩ.cm.

[0038] Etching method: heat the solution to 30°C, put the product into the solution, rotate at a constant speed, the etching time is 3 minutes, and the double-sided etching amount can reach 0.04mm. If you need to increase the amount of etching, you can increase the solution temperature or extend the etching time to achieve the effect. The temperature of the solution cannot be higher than 40°C, o...

Embodiment 2

[0047] An etchant for low-resistance silicon products, by mass percentage, consists of the following substances:

[0048]

[0049] Solution preparation method and etching method are the same as embodiment 1.

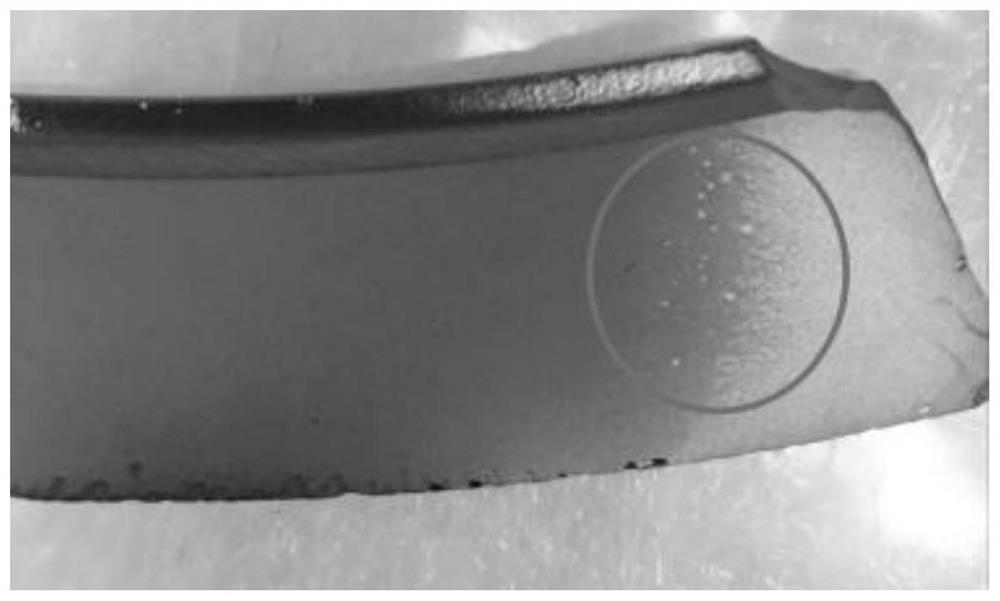

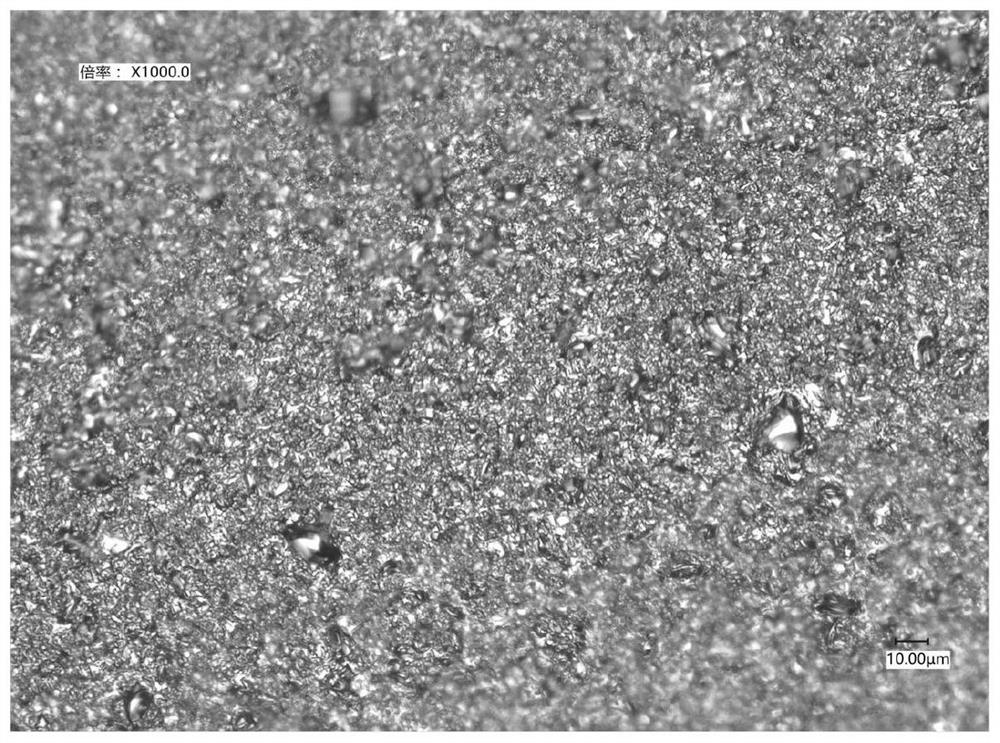

[0050] Figure 7 This is the partial appearance of the sample after etching in this embodiment, the surface is fine and uniform, without color difference or bubble holes.

Embodiment 3

[0052] An etchant for low-resistance silicon products, by mass percentage, consists of the following substances:

[0053]

[0054]

[0055] Solution preparation method and etching method are the same as embodiment 1.

[0056] Figure 8 This is the partial appearance of the sample after etching in this embodiment, the surface is fine and uniform, without color difference or bubble holes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com