Carbon@SiOx/C@carbon nanotube composite material and preparation method thereof

A technology of carbon nanotubes and composite materials, applied in the field of electrochemical energy storage, can solve the problems of material structure pulverization, shedding, volume expansion and low electronic conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

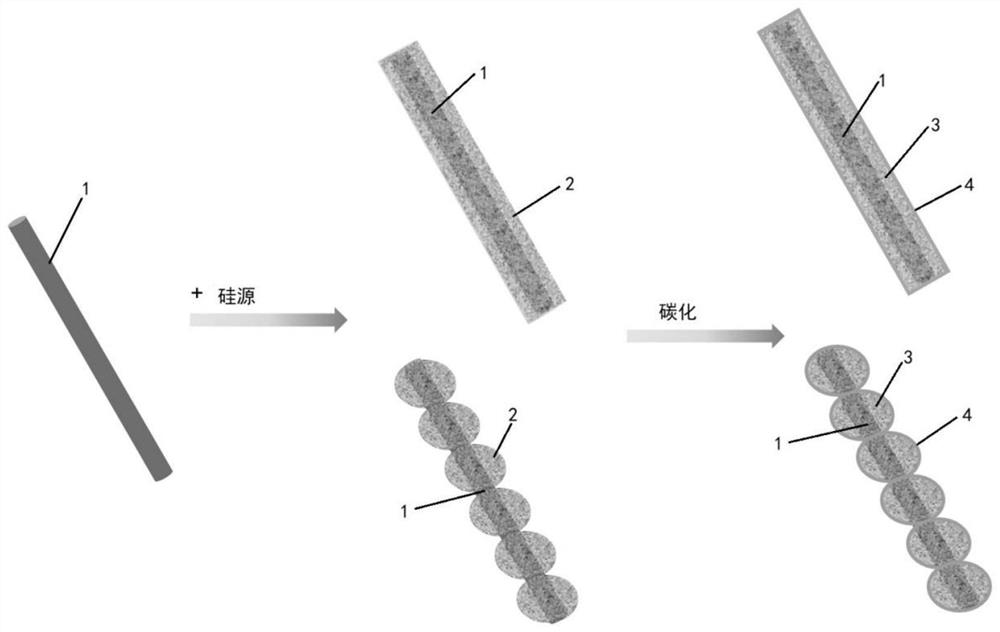

[0040] To solve the above problems, combined with figure 1 , Figure 10 As shown, the embodiment of the present invention provides a carbon @SiO x / C@ carbon nanotube composite material preparation method, the specific steps are:

[0041] S1. Disperse the silicon source and carbon nanotube particles in a mixed solvent, add ammonia water, and obtain the organic silicon@carbon nanotube composite material after centrifugal drying;

[0042]S2. Put the organosilicon@carbon nanotube composite material in a tube furnace, conduct primary carbonization in a protective atmosphere, then pass in organic gas for secondary carbonization, and finally cool to room temperature to obtain carbon@SiO x / C@carbon nanotube composite material.

[0043] The silicon source selected in the embodiment of the present invention is hydrolyzed into silanols in ammonia water, and is adsorbed on the negatively charged carbon nanotubes 1 through hydrogen bonding, and the polycondensation reaction between th...

Embodiment 1

[0055] This example provides a carbon @SiO x / C@ carbon nanotube composite material preparation method, the specific steps are as follows:

[0056] 1) Add 1 mL of vinyltrimethoxysilane and 1.5 mL of single-walled carbon nanotube aqueous solution (3 mg / mL) into 150 mL of distilled water, that is, the volume / mass ratio of silicon source to carbon nanotubes is 0.22, and then 25wt.% ammonia solution was added dropwise at a rate of 1 drop, stirred for 12 hours, centrifuged, washed, and dried to obtain the organosilicon@carbon nanotube composite material.

[0057] 2) Carbonize the dried organosilicon@carbon nanotube composite material in a tube furnace under the protection of argon. The carbonization time is 4 hours, and the carbonization temperature is 800°C, followed by acetylene / argon gas. The mixed gas is carbonized for 30 minutes, the carbonization time is 30 minutes, the carbonization temperature is 800°C, and carbon @SiO is obtained after cooling to room temperature x / C@ca...

Embodiment 2

[0071] The difference between this embodiment and embodiment 1 is:

[0072] In step 1), 0.3 mL of vinyltrimethoxysilane and 2.0 mL of single-walled carbon nanotube aqueous solution (3 mg / mL) were added to 200 mL of distilled water, that is, the volume / mass ratio of silicon source to carbon nanotubes was 0.05, Add 0.3wt.% ammonia water dropwise at a rate of 5 seconds / drop;

[0073] In step 2), the primary carbonization time is 5 hours, and the carbonization temperature is 800°C;

[0074] Other parameters are the same as in Example 1.

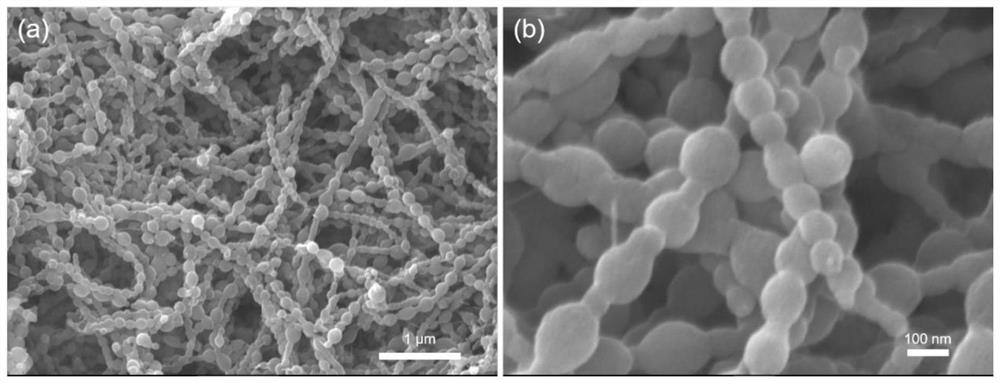

[0075] Figure 8 Carbon@SiO prepared for Example 2 x The SEM image of / C@carbon nanotube composite material, wherein, a) is the 100nm scale figure, b) is the 50nm scale figure, from Figure 8 It can be seen that the carbon@SiO prepared in Example 2 x The morphology of / C@carbon nanotube composites maintains the one-dimensional continuous linear structure of carbon nanotubes, and the shell layer and carbon nanotubes grow on carbon nanotubes c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com