Polyester for heat shrinkable film and preparation method thereof

A heat-shrinkable film and polyester technology, applied in the direction of single-component polyester rayon, rayon manufacturing, textiles and papermaking, etc., can solve the problems of reducing polyester crystallinity, low shrinkage rate, and low shrinkage internal stress , to achieve the effect of reducing crystallinity, high shrinkage rate and high transparency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-5

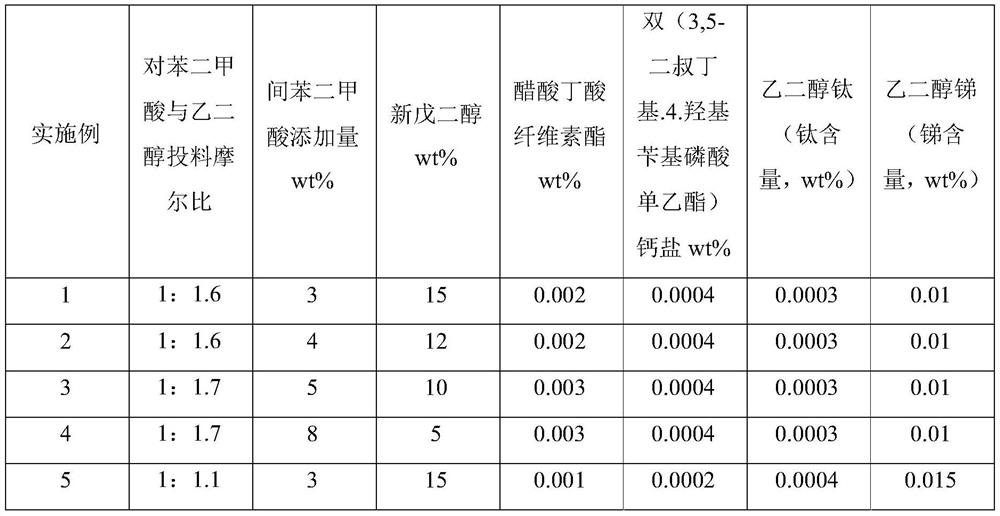

[0038] Example 1-5 Polyester for heat-shrinkable film contains components: terephthalic acid, ethylene glycol, isophthalic acid, neopentyl glycol, cellulose acetate butyrate and bis(3,5-di-tert-butyl Base-4-hydroxybenzylphosphonic acid monoethyl ester) calcium salt, the weight percentage of each component and the feeding ratio of terephthalic acid and ethylene glycol are shown in Table 1. Table 1 shows the weight percent of the catalyst titanium glycolate and antimony glycolate in the total amount of polyester used for heat shrinkable films in the process of preparing polyester for heat shrinkable films.

Embodiment 6-10

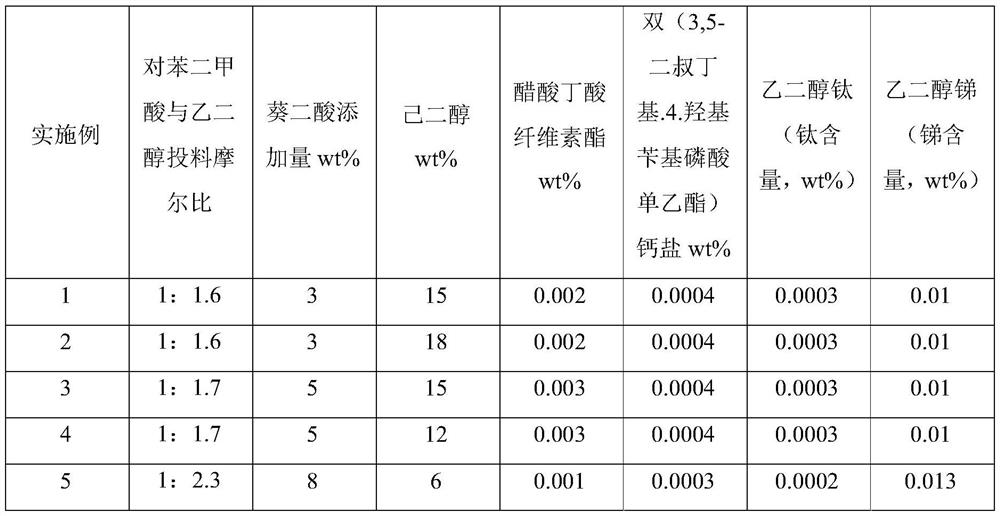

[0039] Example 6-10 Polyester for heat-shrinkable film contains components: terephthalic acid, ethylene glycol, sebacic acid, hexanediol, cellulose acetate butyrate and bis(3,5-di-tert-butyl- 4-Hydroxybenzylphosphonic acid monoethyl ester) calcium salt, the percentage by weight of each component and the feeding ratio of terephthalic acid and ethylene glycol are shown in Table 2. In the process of preparing the polyester for heat-shrinkable film, the addition amount of the catalyst titanium glycolate and antimony glycolate to the total amount of polyester for heat-shrinkable film is shown in Table 2.

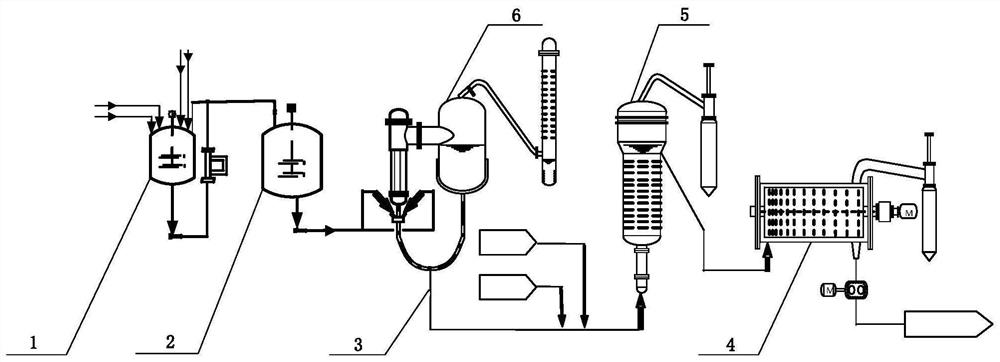

[0040] Example 1-5 The preparation steps of polyester for heat-shrinkable film include: according to the ratio in Table 1, terephthalic acid, ethylene glycol, isophthalic acid, neopentyl glycol and concentration of 0.5wt% ethylene glycol Titanium glycol solution is added into the slurry mixing tank 1 for slurry preparation, and enters the esterification kettle 6 after being meter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com