Diesel adsorbent and preparation method thereof

An adsorbent and diesel technology, which is applied in the field of diesel adsorbent and its preparation, can solve the problems of low restoration rate of biological methods, oil spill restriction, secondary pollution, etc., so as to achieve high-value utilization, reduce impact, and save resources Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

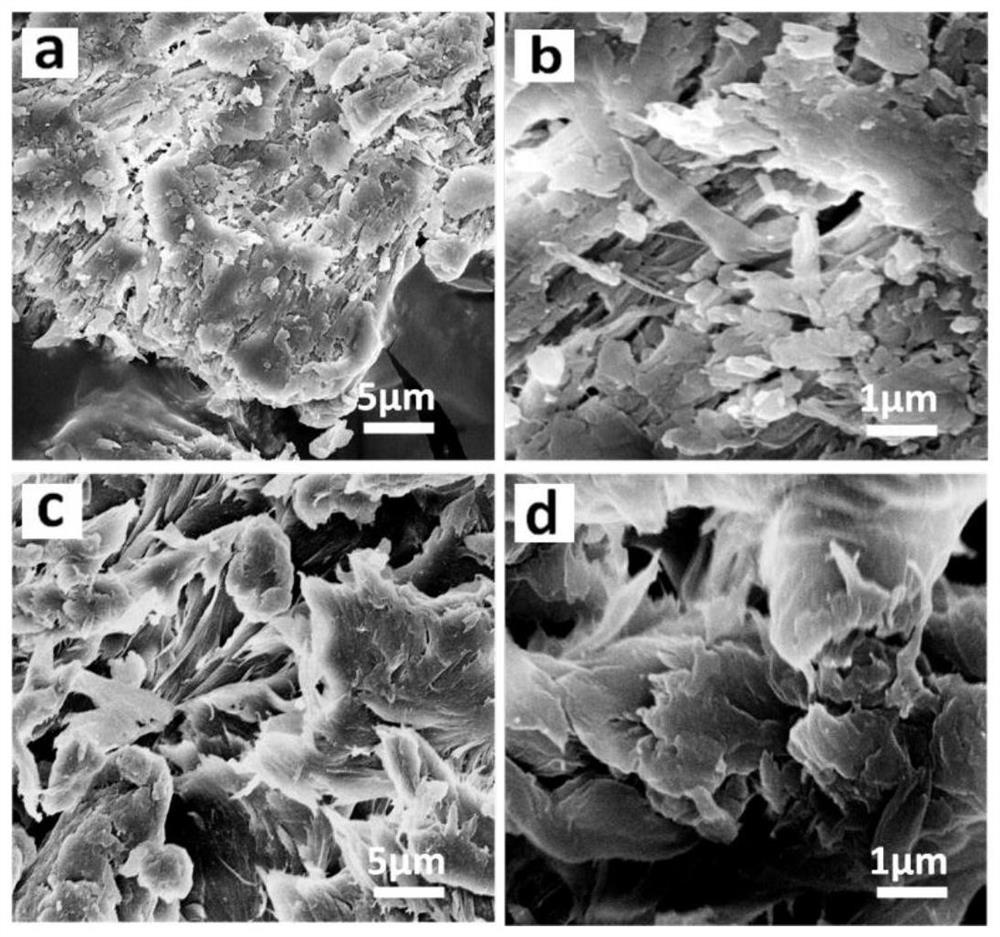

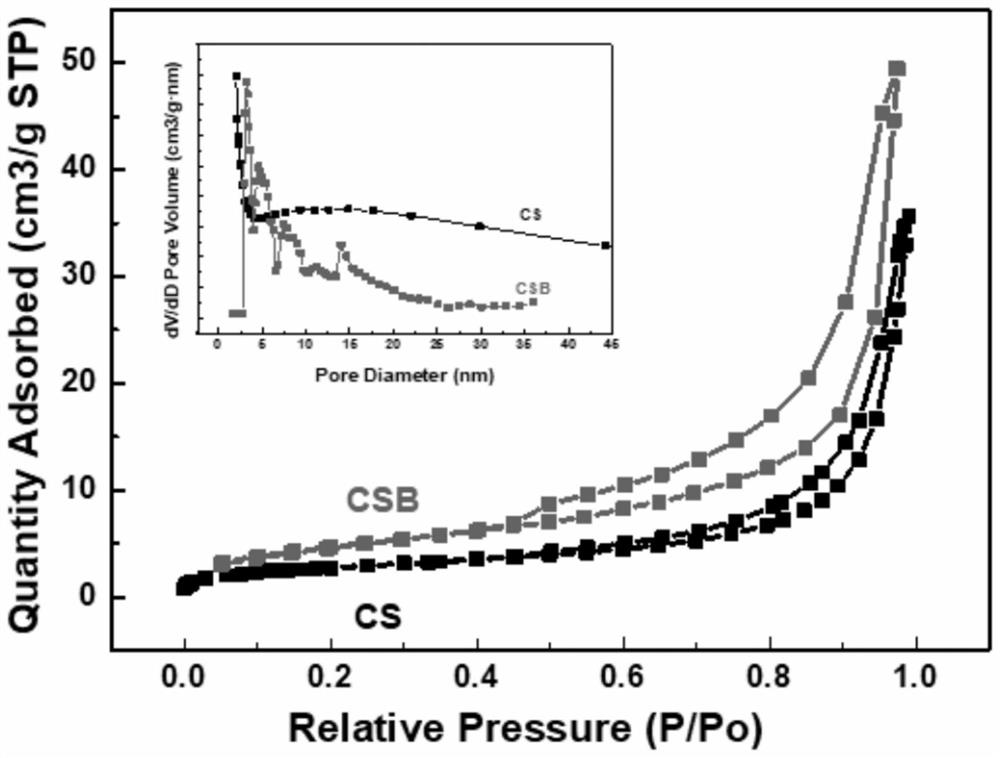

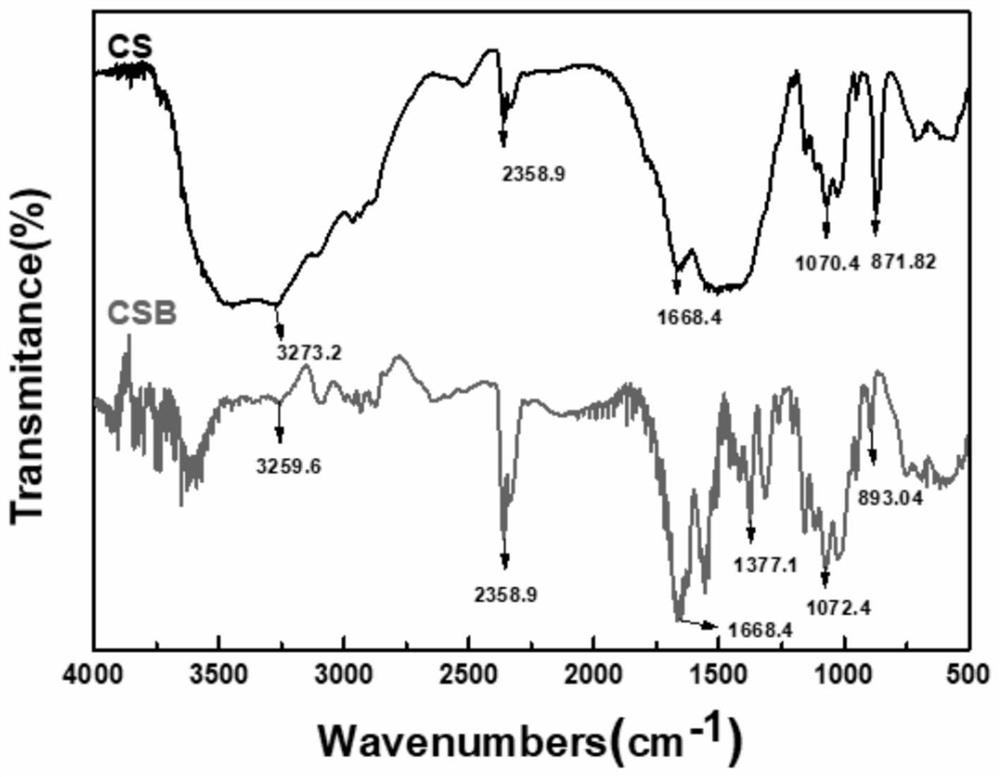

[0056] The preparation of embodiment 1 diesel oil adsorbent

[0057] (1) Crab shell pretreatment

[0058] Scrub 50g of crab shells, dry, grind and crush them through a 100-mesh sieve, soak in 500ml of 6% hydrochloric acid solution at 30°C for 4 hours, wash until neutral, then soak in 500ml of 6% sodium hydroxide solution at 90°C for 2 hours, Then soak in 500ml 50% sodium hydroxide solution at 90°C for 9 hours, wash until neutral, and dry to obtain 16g of pretreated crab shell powder;

[0059] (2) Preparation of pyrolysis biochar

[0060] Put 16g of dried and pulverized crab shell powder in step (1), add water and acetic acid, place it in the reaction kettle according to the weight ratio of crab shell powder: water: acetic acid = 1:5:5, compact the lid tightly and place it in the oven Pyrolysis at 180°C for 10 hours; get 2.8g of biochar after pyrolysis;

[0061] (3) Preparation of diesel adsorbent

[0062] Centrifuge 2.8 g of pyrolyzed biochar prepared in step 2) at 5000 r / ...

Embodiment 2

[0065] Embodiment 2 diesel oil adsorbent is to the adsorption of diesel oil (different adsorption time)

[0066] 1) get the diesel oil sorbent 0.01g among the embodiment 1 and 100mL concentration is the diesel oil waste water solution mixing of 6g / L;

[0067] 2) By adding 0.1mol / L hydrochloric acid or 0.1mol / L sodium hydroxide, the pH value of the mixed solution is adjusted to 7, and adsorbed at room temperature for different times; the mixed solution after adsorption is obtained;

[0068] 3) Centrifuge the mixed solution after adsorption at 5000r / min for 10min, take the supernatant to measure its OD value, calculate the adsorption capacity and adsorption rate of diesel oil by formula (1)(2), the results are shown in Table 1 and Figure 5 shown.

[0069] It can be seen from Table 1 that the adsorption of diesel oil increases rapidly first, and reaches adsorption equilibrium at 180 minutes, with a maximum adsorption rate of 80.1%.

[0070] Table 1

[0071] Adsorpti...

Embodiment 3

[0072] Embodiment 3 The adsorption of diesel oil adsorbent to diesel oil (different adsorbent dosage)

[0073] 1) get the diesel oil sorbent 0.005g, 0.01g, 0.015g, 0.02g, 0.025g in embodiment 1 and mix with 100mL concentration respectively the diesel oil waste water solution of 6g / L;

[0074] 2) Adjust the pH value of the mixed solution to 7 by adding 0.1mol / L hydrochloric acid or 0.1mol / L sodium hydroxide, and adsorb at room temperature for 180min;

[0075] 3) Centrifuge the mixed solution after adsorption at 5000r / min for 10min, take the supernatant to measure its OD value, calculate the adsorption capacity and adsorption rate of diesel oil by formula (1) (2), the results are shown in Table 2 and Image 6 shown.

[0076] It can be seen from Table 2 that in the range of 0.005-0.025g, with the increase of the amount of diesel adsorbent, the adsorption capacity of diesel adsorbent to diesel increases sharply, and then gradually tends to be flat.

[0077] Table 2

[0078] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com