Heteropolyacid etched capsule-shaped hollow porous carbon shell, preparation method and application of heteropolyacid etched capsule-shaped hollow porous carbon shell in lithium-sulfur battery

A hollow porous, lithium-sulfur battery technology, used in lithium batteries, carbon preparation/purification, battery electrodes, etc., can solve the problems of obvious shuttle effect, low sulfur loading, and poor cycle stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Example 1 A method for preparing a heteropolyacid-etched capsule-shaped hollow porous carbon shell

[0034] Include the following steps:

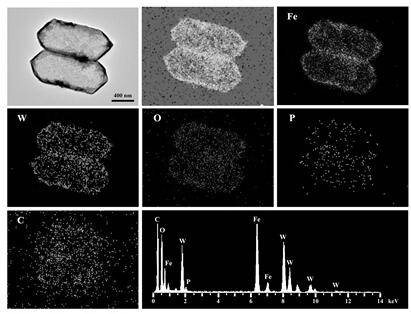

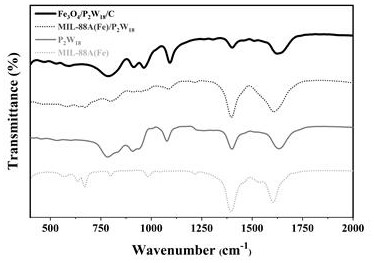

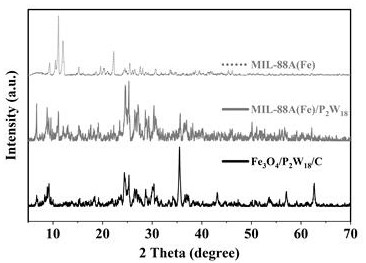

[0035] 1. Preparation of Fe 3 o 4 / P 2 W 18 / C composite material

[0036] (1) Preparation of organic framework material MIL-88A(Fe):

[0037] Dissolve 1.3 g of fumaric acid in 100 mL of a mixed solution of N,N-dimethylformamide and absolute ethanol at a ratio of 1:1 (volume ratio), ultrasonicate and stir for 30 min, then add 3 g of ferric nitrate and continue Stir at room temperature for 24 h. After the reaction is completed, the product is collected by centrifugation, washed repeatedly with deionized water three times, and vacuum-dried to obtain the metal-organic framework material MIL-88A(Fe).

[0038] The chemical formula of the above MIL-88A(Fe) is C 12 h 6 o 13 Fe 3 .

[0039] (2) MIL-88A(Fe) / P 2 W 18 Preparation of composite materials:

[0040] Take 1 g metal-organic framework material MIL-88A(Fe) and place it i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Average pore diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com