A Biogas Slurry Purification Method Based on the Symbiosis of Bacteria and Algae

A technology of bacteria and algae symbiosis and biogas slurry, which is applied in the direction of microorganism-based methods, biochemical equipment and methods, chemical instruments and methods, etc., can solve the problems of inconspicuous treatment effect and low COD removal rate, and improve the purification of biogas slurry effect, enhanced absorption efficiency, good fixation and growth effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] This embodiment provides a biogas slurry purification method based on the symbiosis of bacteria and algae, including the following steps:

[0054] (1) Biogas slurry pretreatment

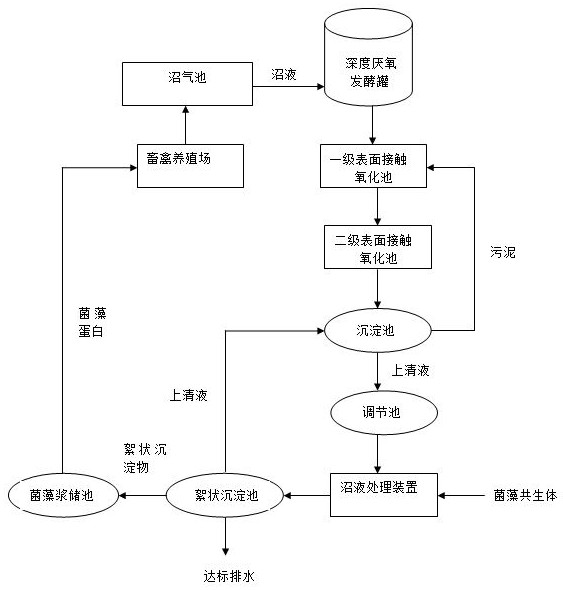

[0055] The biogas slurry to be treated is introduced into the deep anaerobic fermentation tank for fermentation, and then introduced into the first-level surface contact oxidation tank and the second-level surface contact oxidation tank for water purification, and then enters the sedimentation tank to remove the suspended matter in the biogas slurry, and the suspended matter is formed The sludge returns to the first-level surface contact oxidation tank to continue to participate in water purification, and its supernatant enters the adjustment tank to adjust the pH of the biogas slurry to 5 and the dilution to 15;

[0056] (2) Biogas slurry purification

[0057] Import the pretreated biogas slurry into the biogas slurry treatment device, then add hypochlorous acid in an amount of 0.02g / L for s...

Embodiment 2

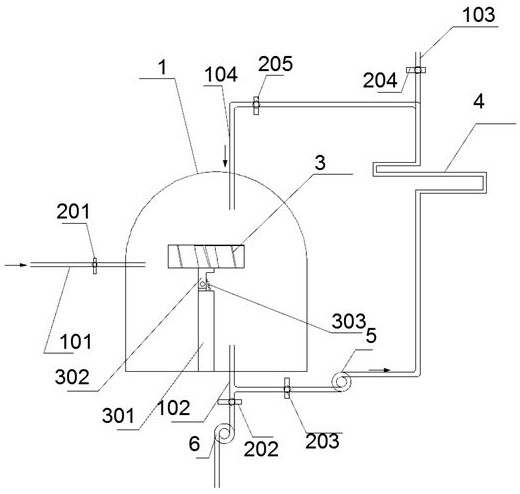

[0061] On the basis of Embodiment 1, this embodiment also provides a biogas slurry treatment device, including a circulation tank 1, a circulation water pump 5 and a cultivation pipeline 4, two water inlet pipes and one water outlet pipe are arranged on the circulation tank 1, They are respectively the first water inlet pipe 101, the second water inlet pipe 104 and the water outlet pipe 102. The water outlet pipe is provided with a water pump 6. The cultivation pipeline 4 includes several tubular bioreactors connected end to end. The cultivation pipeline 4 A third water inlet pipe 103 in the opening direction is also arranged above the cultivation pipeline 4 . The interior of the circulation tank 1 is provided with an impeller device, which includes an impeller fixing seat 301, an impeller support 302, a spring 303 and an impeller 3, and the impeller fixing seat 301 is fixedly installed at the bottom of the circulation tank 1, and the lower part is a cylinder , the upper part ...

Embodiment 3

[0064] On the basis of Example 1, this example also provides a method for preparing a symbiont of bacteria and algae, specifically:

[0065] S1. Under sterile conditions, inoculate Chlorella into a conical flask containing BG11 medium at an inoculum amount of 20%, and then put it into a photoreactor to cultivate for 10 days at a culture temperature of 26°C and a light intensity of 2000Lx, get chlorella algae liquid;

[0066] S2, under aseptic conditions, inoculate Bacillus sobria, Rhodopseudomonas palustris, and nitrifying bacteria into the Erlenmeyer flasks with LB medium, then put them into a shaker at 200 rpm for 10 days, and the culture temperature is At 27°C, a mixed bacterial solution was obtained;

[0067] S3. Cut the loofah pulp into sections according to the specification of φ1mm*10mm, then wash and sterilize, and divide it into part A and part B according to the length ratio of 1:1 to obtain the pretreated loofah carrier;

[0068] S4, get the chlorella algae liquid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com