Copper tungstate photo-anode film and preparation method thereof

A technology of copper tungstate and photoanode, applied in the direction of electrodes, liquid chemical plating, coating, etc., can solve the problems of uncontrollable thickness and performance of copper tungstate film, many surface defects, poor repeatability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

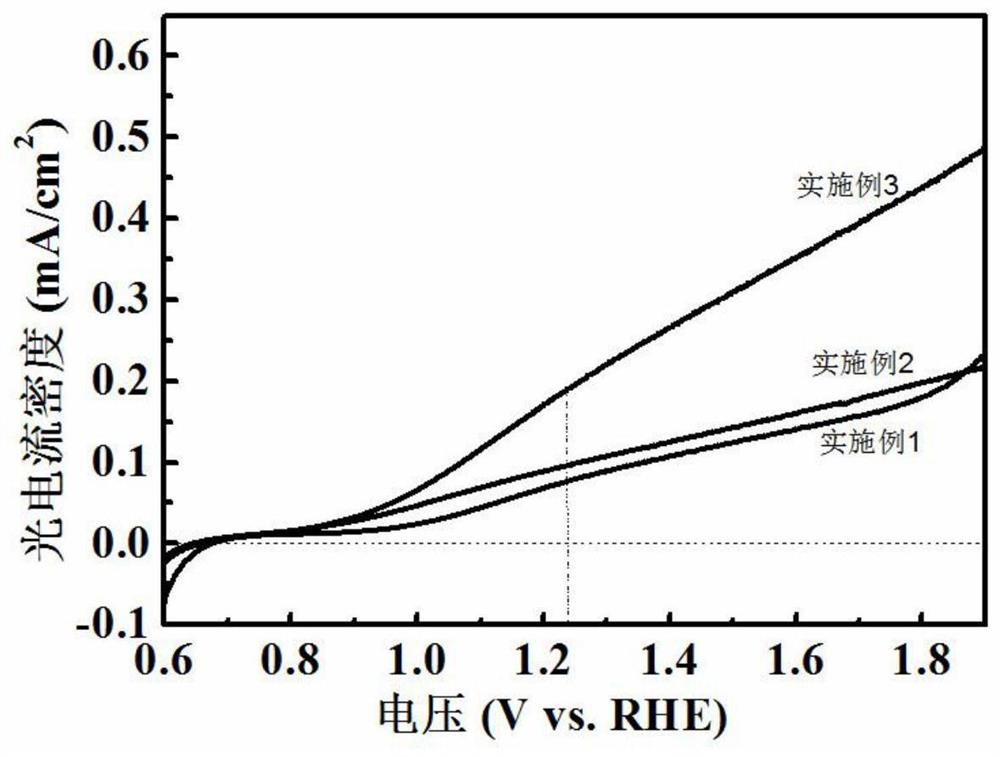

Examples

preparation example Construction

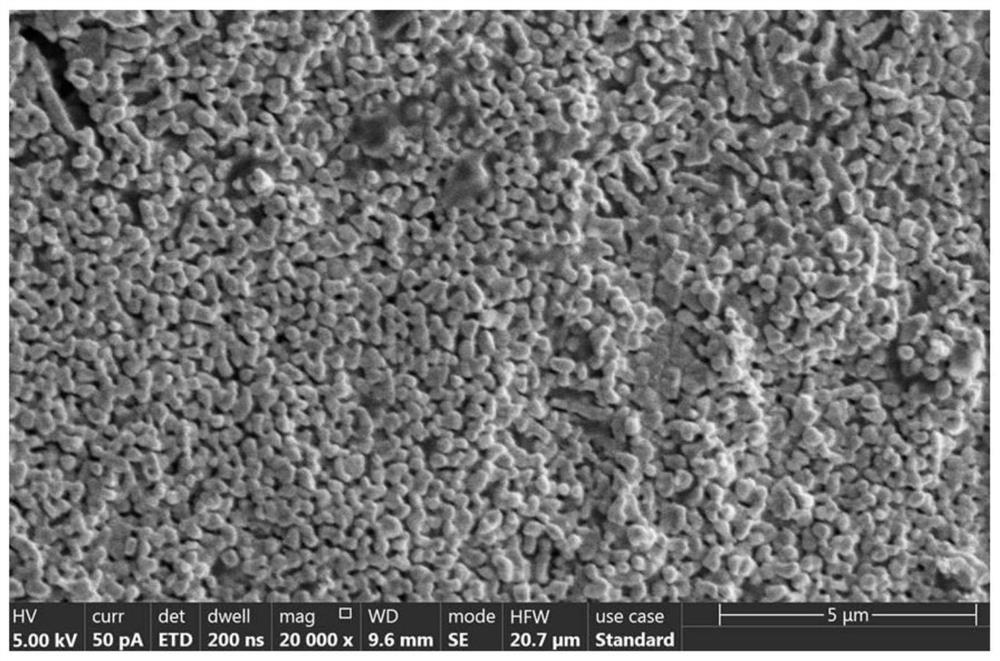

[0023] The invention provides a kind of preparation method of copper tungstate photoanode film, comprising the following steps:

[0024] (1) Mix copper nitrate trihydrate, ammonium metatungstate and water to obtain a precursor solution;

[0025] (2) carry out ultrasonic spray pyrolytic coating to the precursor solution that described step (1) obtains, form copper tungstate precursor thin film on substrate;

[0026] (3) heat-treating the copper tungstate precursor film obtained in the step (2) to obtain a copper tungstate photoanode film.

[0027] The invention mixes copper nitrate trihydrate, ammonium metatungstate and water to obtain a precursor solution. In the present invention, the copper nitrate trihydrate is preferably analytically pure; the ammonium metatungstate is preferably analytically pure; the water is preferably deionized water. In the present invention, the sources of the copper nitrate trihydrate, ammonium metatungstate and water are not particularly limited,...

Embodiment 1

[0049] Reagents: acetone of analytical grade, anhydrous ethanol of analytical grade, copper nitrate trihydrate with a purity of 99.9 wt%, and ammonium metatungstate with a purity of 99.5 wt%.

[0050] Device: MSK-USP-04C Ultrasonic Atomization Coating Apparatus produced by Shenyang Kejing Automation Equipment Co., Ltd.

[0051] Preparation:

[0052] (1) Cleaning of the substrate

[0053] Using conductive glass as the substrate, the substrate was ultrasonically cleaned in acetone, absolute ethanol, and deionized water for 15 minutes, and then used.

[0054] (2), the configuration of the precursor liquid

[0055] Dissolve 2.416g of copper nitrate trihydrate into 200mL of deionized water, stir until clear, then weigh 2.4636g of ammonium metatungstate and add it to the above solution, continue stirring until clear, and let it stand for 30 minutes to obtain a precursor solution. (Wherein, the concentration of copper ions in the precursor solution is 0.05mol / L, and the ratio of t...

Embodiment 2

[0062] Reagents: acetone of analytical grade, anhydrous ethanol of analytical grade, copper nitrate trihydrate with a purity of 99.9 wt%, and ammonium metatungstate with a purity of 99.5 wt%.

[0063] Device: MSK-USP-04C Ultrasonic Atomization Coating Apparatus produced by Shenyang Kejing Automation Equipment Co., Ltd.

[0064] Preparation:

[0065] (1) Cleaning of the substrate

[0066] Use conductive glass as the substrate, ultrasonically clean the substrate in acetone, absolute ethanol, and deionized water for 15 minutes, and set aside;

[0067] (2), the configuration of the precursor liquid

[0068] Dissolve 4.832g of copper nitrate trihydrate into 200mL of deionized water, stir until clear, then weigh 4.9272g of ammonium metatungstate and add it to the above solution, continue stirring until clear, and let it stand for 30 minutes to obtain a precursor solution. (Wherein, the concentration of copper ions in the precursor solution is 0.1mol / L, and the ratio of the amount...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com