Nickel-gallium alloy catalyst as well as preparation method and application thereof

A technology of alloy catalyst and catalyst, which is applied in the direction of catalyst activation/preparation, chemical instruments and methods, metal/metal oxide/metal hydroxide catalyst, etc., and can solve the problem of difficult to obtain carbon nanotubes, sintered growth, carbon nanomaterials Shape and size are difficult to control and other problems, to achieve good anti-sintering ability, reduce the degree of metal sintering, and good catalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

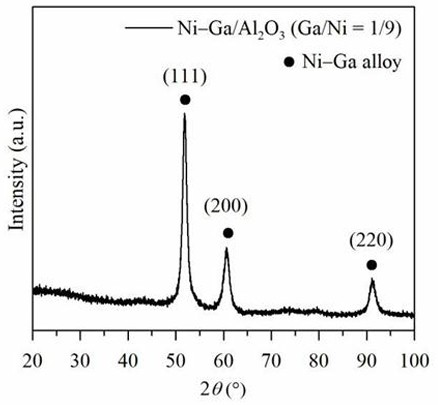

[0038] A nickel-gallium alloy catalyst, the specific preparation steps are as follows: Weigh 20g of NaOH solid, dissolve it in 250mL of deionized water, and prepare a 2 mol / L NaOH aqueous solution as a precipitant. Weigh 8.3894g Ni(NO 3 ) 2 ·6H 2 O, 1.3391g Ga(NO 3 ) 3 9H 2 O, 4.0084g Al(NO 3 ) 3 9H 2 O was dissolved in 100 mL deionized water to obtain a mixed solution of metal salts. Weigh 0.7361g Na 2 CO 3 Dissolve in 100 mL deionized water as the base solution. The metal salt mixed solution was dropped into Na at a rate of 30 drops / min using a dropping funnel. 2 CO 3 solution with constant stirring. At the same time, use a peristaltic pump to drip NaOH solution into the solution at a rate of 30 drops / min, maintain the pH of the solution = 10 ± 0.5, continue stirring for 1 h after the addition is complete, then let it stand for 24 h, filter and wash with deionized water to pH = 7 ± 0.2, the filter cake was dried at 100°C for 12 h to obtain a hydrotalcite-like p...

Embodiment 2

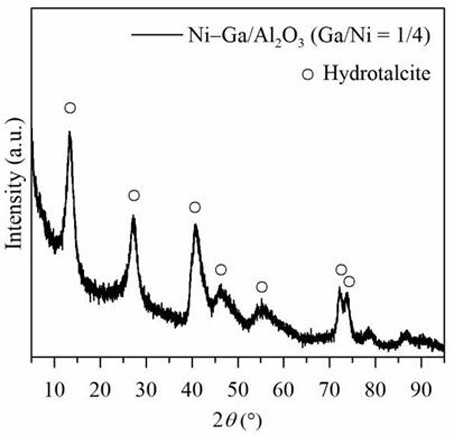

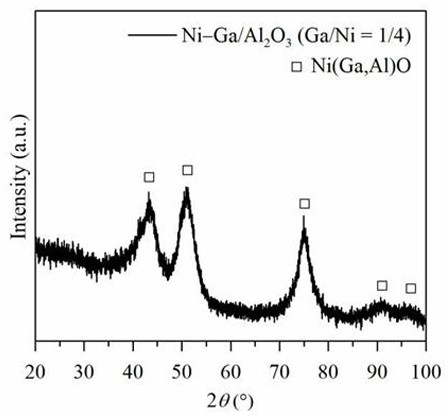

[0041] A nickel-gallium alloy catalyst, the specific preparation steps are as follows: Weigh 20g of NaOH solid, dissolve it in 250mL of deionized water, and prepare a 2 mol / L NaOH aqueous solution as a precipitant. Weigh 7.3086g Ni(NO 3 ) 2 ·6H 2 O, 2.6248g Ga(NO 3 ) 3 9H 2 O, 3.9285g Al(NO 3 ) 3 9H 2 O was dissolved in 100 mL deionized water to obtain a mixed solution of metal salts. Weigh 0.8880g Na 2 CO 3 , dissolved in 100 mL deionized water as the base solution. The metal salt mixed solution was dropped into Na at a rate of 30 drops / min using a dropping funnel. 2 CO 3 solution with constant stirring. At the same time, use a peristaltic pump to drip NaOH solution into the solution at a rate of 30 drops / min, maintain the pH of the solution = 10 ± 0.5, continue stirring for 1 h after the addition is complete, then let it stand for 24 h, filter and wash with deionized water to pH = 7 ± 0.2, the filter cake was dried at 100°C for 12 h to obtain a hydrotalcite-lik...

Embodiment 3

[0049] A nickel-gallium alloy catalyst, the specific preparation steps are as follows: Weigh 20g of NaOH solid, dissolve it in 250mL of deionized water, and prepare a 2 mol / L NaOH aqueous solution as a precipitant. Weigh 6.7842g Ni(NO 3 ) 2 ·6H 2 O, 3.2487g Ga(NO 3 ) 3 9H 2 O, 3.8897g Al(NO 3 ) 3 9H 2 O was dissolved in 100 mL deionized water to obtain a mixed solution of metal salts. Weigh 0.9616g Na 2 CO 3 , dissolved in 100 mL deionized water as the base solution. The metal salt mixed solution was dropped into Na at a rate of 30 drops / min using a dropping funnel. 2 CO 3solution with constant stirring. At the same time, use a peristaltic pump to drip NaOH solution into the solution at a rate of 30 drops / min, maintain the pH of the solution = 10 ± 0.5, continue stirring for 1 h after the addition is complete, then let it stand for 24 h, filter and wash with deionized water to pH = 7 ± 0.2, the filter cake was dried at 100°C for 12 h to obtain a hydrotalcite-like...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average grain size | aaaaa | aaaaa |

| Average grain size | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com