Method for preparing bismuth vanadate film through two-step spray pyrolysis and application thereof

A technology of spray pyrolysis and bismuth vanadate, which is applied in the fields of chemical instruments and methods, hydrogen production, physical/chemical process catalysts, etc. It can solve the problems of extremely high equipment requirements, low yield, and difficult control of electrodeposition experimental conditions, etc. problem, to achieve the effect of cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

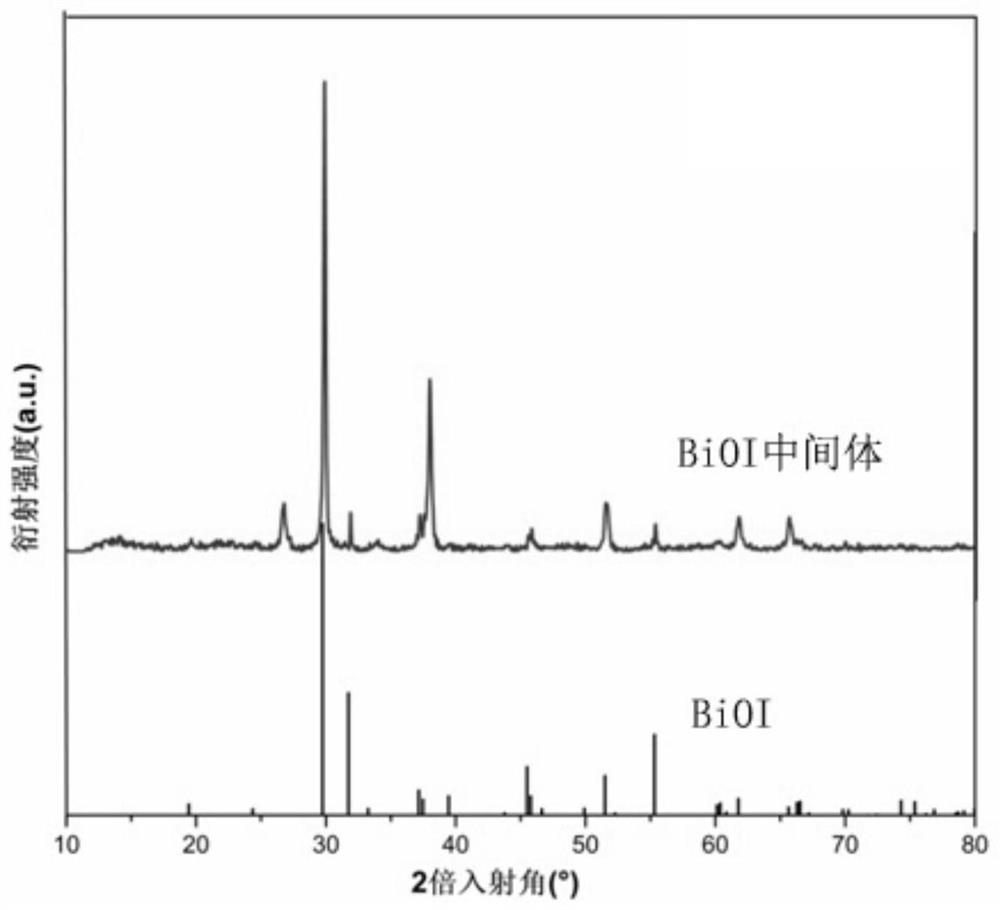

[0028] Dissolve bismuth nitrate pentahydrate in ethylene glycol solution to obtain a bismuth nitrate solution with a concentration of 0.02mol / L; dissolve ammonium iodide in ethylene glycol solution to obtain a 0.02mol / L ammonium iodide solution; mix bismuth nitrate solution with The ammonium iodide solution was uniformly mixed, methanol was added, and the viscosity of the mixed solution was controlled to be 20 cps to obtain a precursor solution.

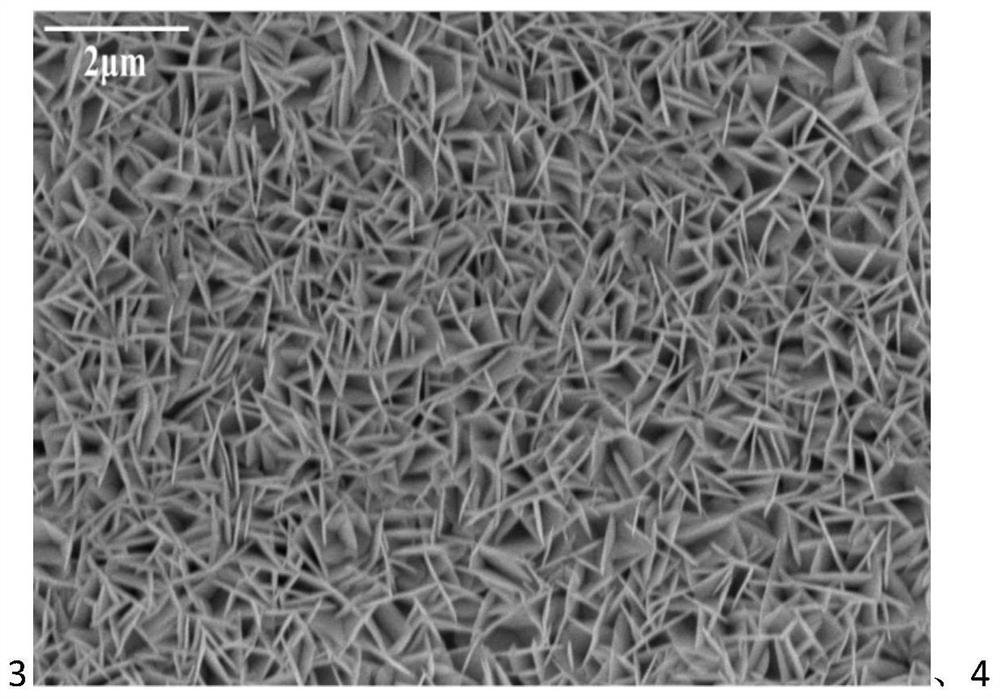

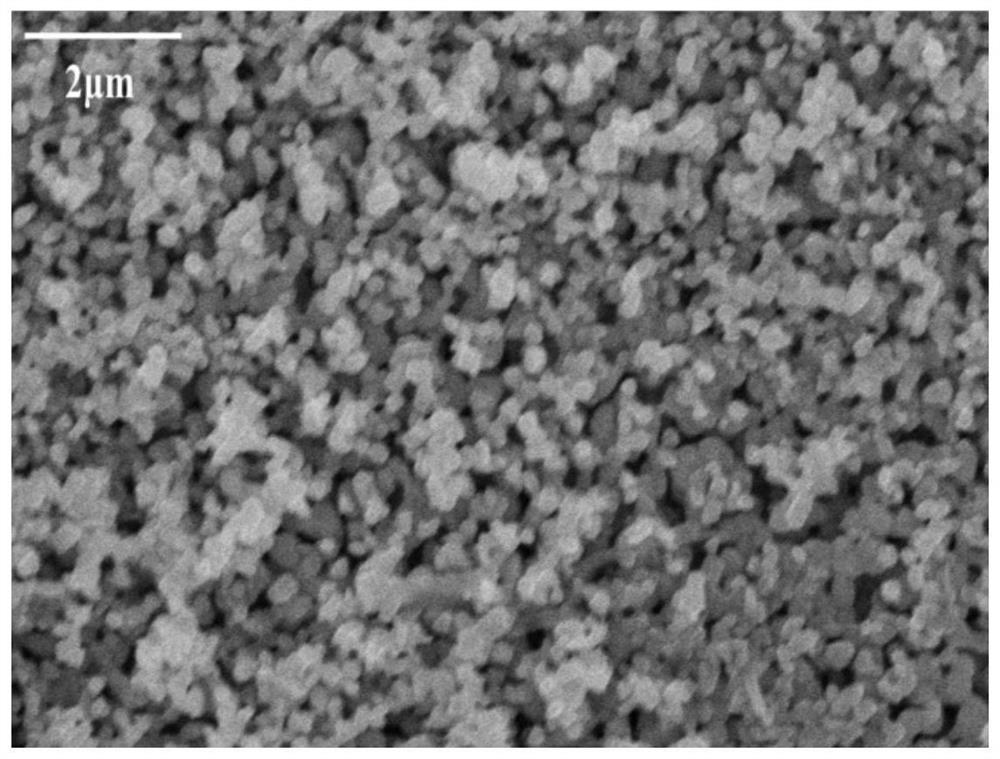

[0029] The area of the FTO conductive glass is 20cm×20cm. The temperature of the FTO conductive glass substrate is controlled to 200°C by using a flat heating table, and the precursor solution at room temperature is atomized and sprayed on the FTO glass substrate by using a high-speed airflow atomization or ultrasonic atomization device. , the control spraying speed is 0.1 ml / cm2 / min, and the typical total amount of spraying is 5 ml / cm2. A BiOI thin film with a thickness of about 550 nm was formed on the FTO glass substrate.

[00...

Embodiment 2

[0034] Dissolve bismuth nitrate pentahydrate in ethylene glycol solution to obtain a bismuth nitrate solution with a concentration of 0.02mol / L; dissolve ammonium iodide in ethylene glycol solution to obtain a 0.1mol / L ammonium iodide solution; mix bismuth nitrate solution with The ammonium iodide solution was uniformly mixed, methanol was added, and the viscosity of the mixed solution was controlled to be 26 cps, which was the precursor solution.

[0035] The area of the FTO conductive glass is 20cm×20cm. The temperature of the FTO conductive glass substrate is controlled to 400°C by using a flat heating table, and the precursor solution at room temperature is atomized and sprayed on the FTO glass substrate by using a high-speed airflow atomization or ultrasonic atomization device. , the control spraying speed is 0.5 ml / cm2 / min, and the typical spraying amount is 10 ml / cm2. A BiOI thin film with a thickness of about 700 nm was formed on the FTO glass substrate.

[0036]0.5...

Embodiment 3

[0038] Dissolve bismuth nitrate pentahydrate in ethylene glycol solution to obtain a bismuth nitrate solution with a concentration of 0.02mol / L; dissolve ammonium iodide in ethylene glycol solution to obtain a 0.04mol / L ammonium iodide solution; mix bismuth nitrate solution with The ammonium iodide solution was uniformly mixed, methanol was added, and the viscosity of the mixed solution was controlled to be a precursor solution of 12 cps.

[0039] The area of the FTO conductive glass is 20cm×20cm. The temperature of the FTO conductive glass substrate is controlled to 320°C by using a flat heating table, and the precursor solution at room temperature is atomized and sprayed on the FTO glass substrate by using a high-speed airflow atomization or ultrasonic atomization device. , the control spraying speed is 0.1 ml / cm2 / min, and the typical total amount of spraying is 5 ml / cm2. A BiOI thin film with a thickness of about 460 nm was formed on the FTO glass substrate.

[0040] 0.5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com