Flame-retardant silane cross-linked nano-modified polyolefin pre-dispersed master batch auxiliary

A nano-modification and silane cross-linking technology, which is applied in the field of flame retardant additives, can solve the problems of large filling amount of flame retardants, decreased mechanical properties, poor matrix compatibility, etc., and achieves excellent flame retardant properties, improved mechanical properties, The effect of enhancing binding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

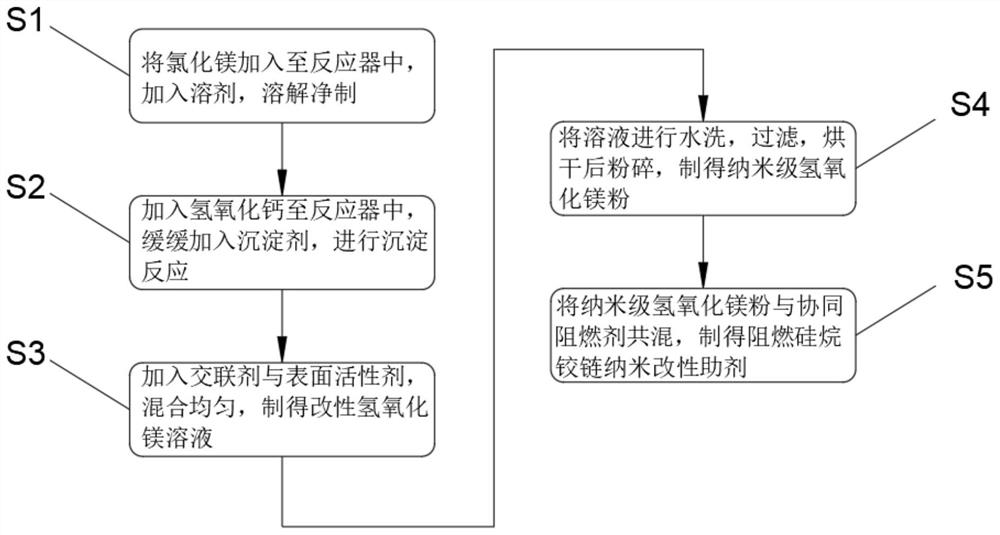

Method used

Image

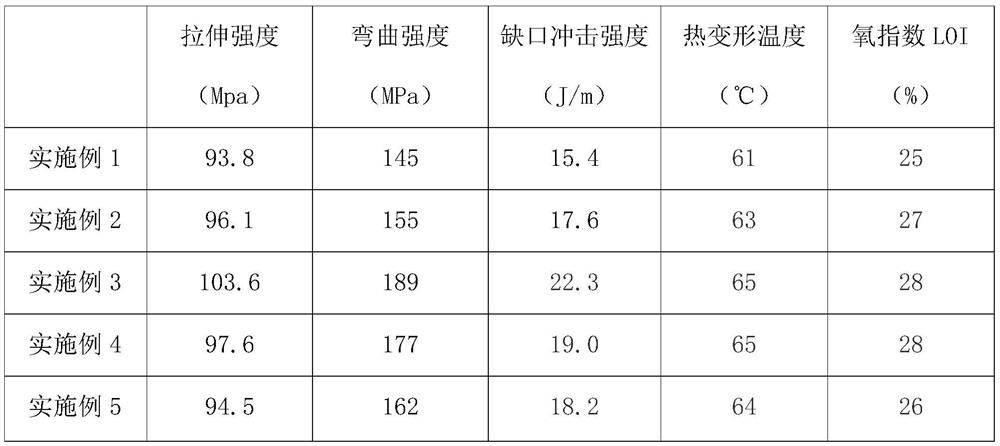

Examples

Embodiment 1

[0032] Embodiment 1 A flame-retardant silane crosslinked nano-modified polyolefin pre-dispersed masterbatch additive and its preparation method, comprising:

[0033] 1. Preparation of nanoscale antimony trioxide

[0034] Dissolve antimony trichloride in high-concentration hydrogen chloride, and magnetically stir to dissolve it completely; slowly drop deionized water into the solution under stirring to form a precipitate; wash away free impurities with water, then add ammonia water to the precipitate, and boil to remove chlorine ions; after washing with water, filtering and drying, nano-scale antimony trioxide powder is obtained;

[0035] The synergistic flame retardant is blended with magnesium hydroxide, so that the composite flame retardant is used in PVC soft and hard products. In addition to excellent flame retardant performance, its mechanical properties have reached the standard, its electrical properties and processing properties are good, and it has Certain smoke supp...

Embodiment 2

[0039] Embodiment 2 A flame-retardant silane crosslinked nano-modified polyolefin pre-dispersed masterbatch additive and its preparation method, comprising:

[0040] 1. Preparation of nanoscale antimony trioxide

[0041] Dissolve antimony trichloride in high-concentration hydrogen chloride, and magnetically stir to dissolve it completely; slowly drop deionized water into the solution under stirring to form a precipitate; wash away free impurities with water, then add ammonia water to the precipitate, and boil to remove chlorine ions; after washing with water, filtering and drying, nano-scale antimony trioxide powder is obtained;

[0042] The synergistic flame retardant is blended with magnesium hydroxide, so that the composite flame retardant is used in PVC soft and hard products. In addition to excellent flame retardant performance, its mechanical properties are up to the standard, its electrical properties and processing properties are good, and it has Certain smoke suppres...

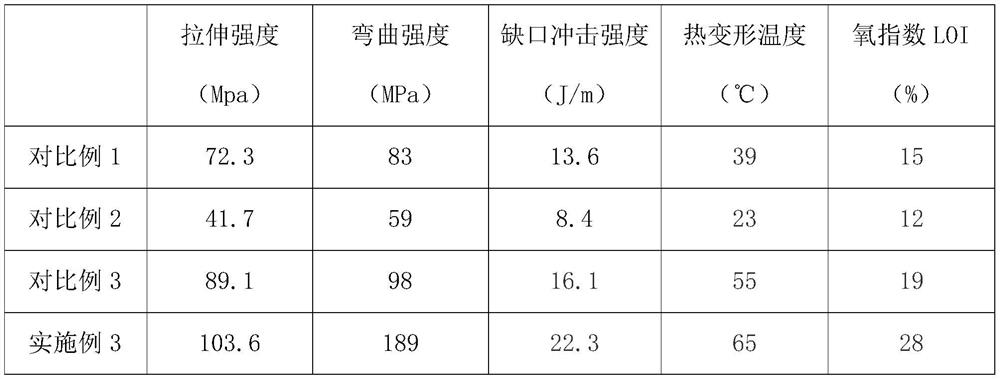

Embodiment 3

[0046] Embodiment 3 A flame-retardant silane crosslinked nano-modified polyolefin pre-dispersed masterbatch additive and its preparation method, comprising:

[0047] 1. Preparation of nanoscale antimony trioxide

[0048]Dissolve antimony trichloride in high-concentration hydrogen chloride, and magnetically stir to dissolve it completely; slowly drop deionized water into the solution under stirring to form a precipitate; wash away free impurities with water, then add ammonia water to the precipitate, and boil to remove chlorine ions; after washing with water, filtering and drying, nano-scale antimony trioxide powder is obtained;

[0049] The synergistic flame retardant is blended with magnesium hydroxide, so that the composite flame retardant is used in PVC soft and hard products. In addition to excellent flame retardant performance, its mechanical properties are up to the standard, its electrical properties and processing properties are good, and it has Certain smoke suppress...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Heat distortion temperature | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com