Light flexible flame-retardant broadband polyvinyl wave-absorbing material and preparation method thereof

A polyethylene-based, wave-absorbing material technology, used in antennas, electrical components, etc., can solve the problems of hydrolysis resistance, insufficient mechanical properties, and high water absorption, and achieve low water absorption, superior wave absorption, and high foaming ratio. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

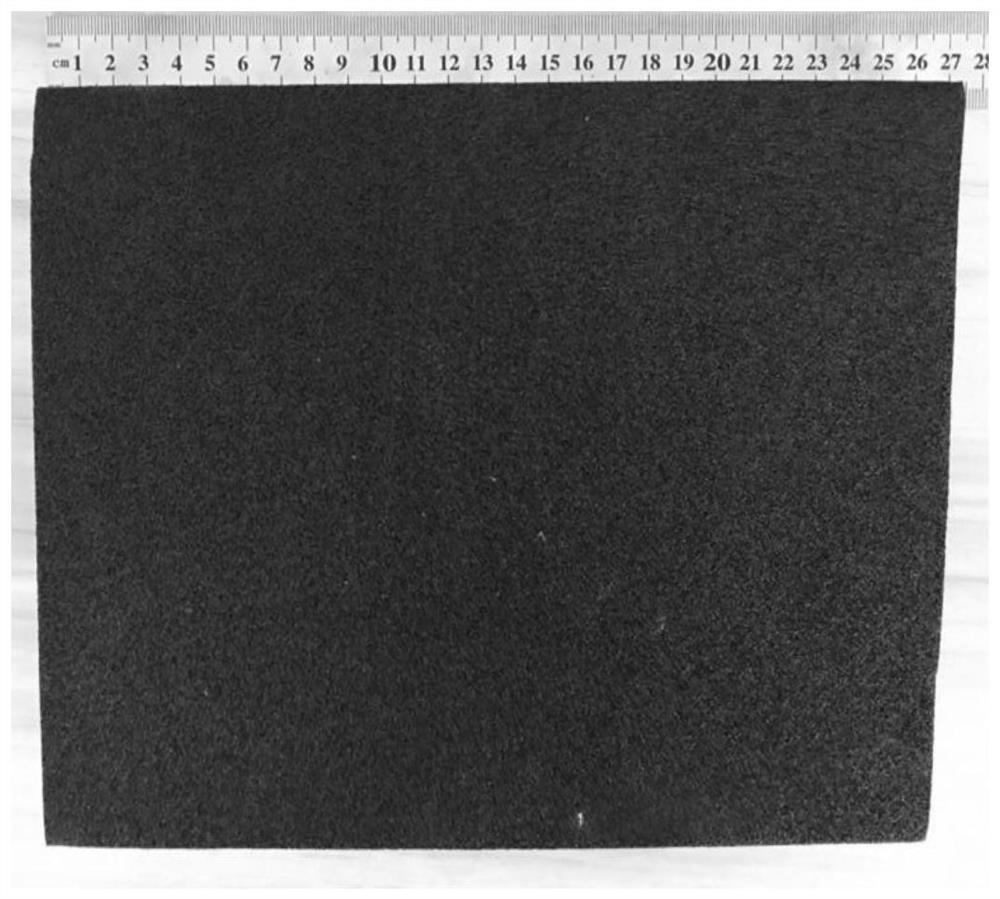

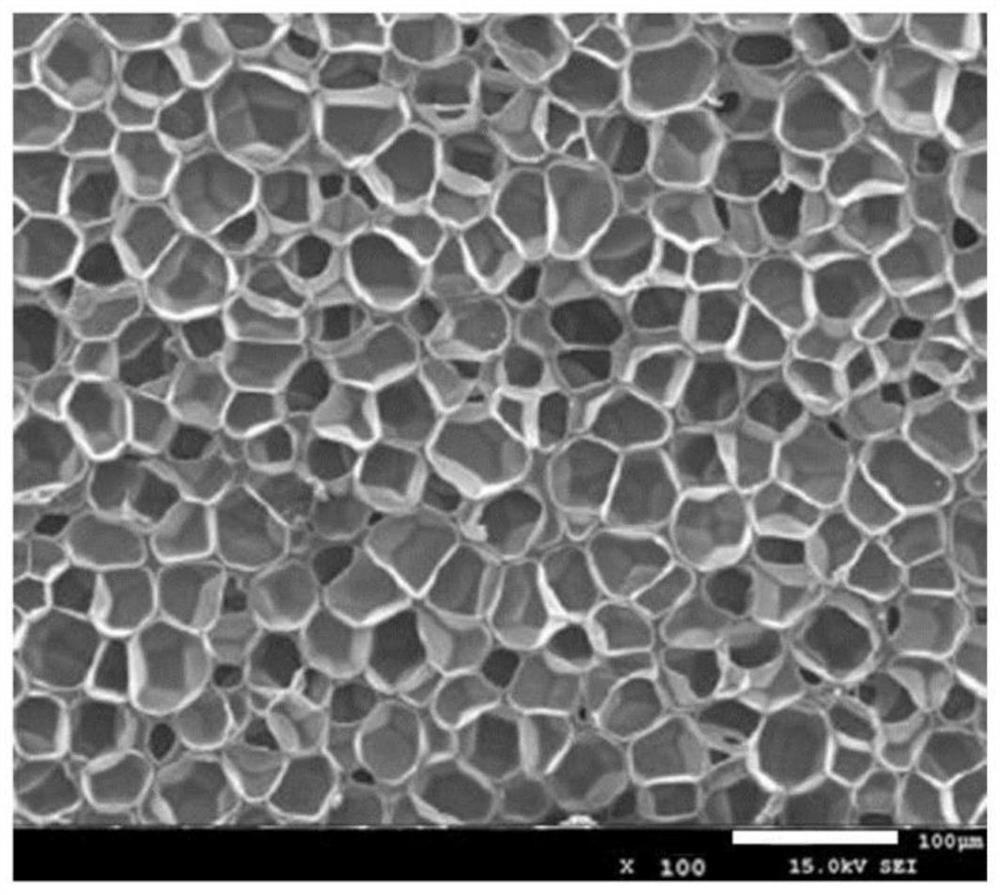

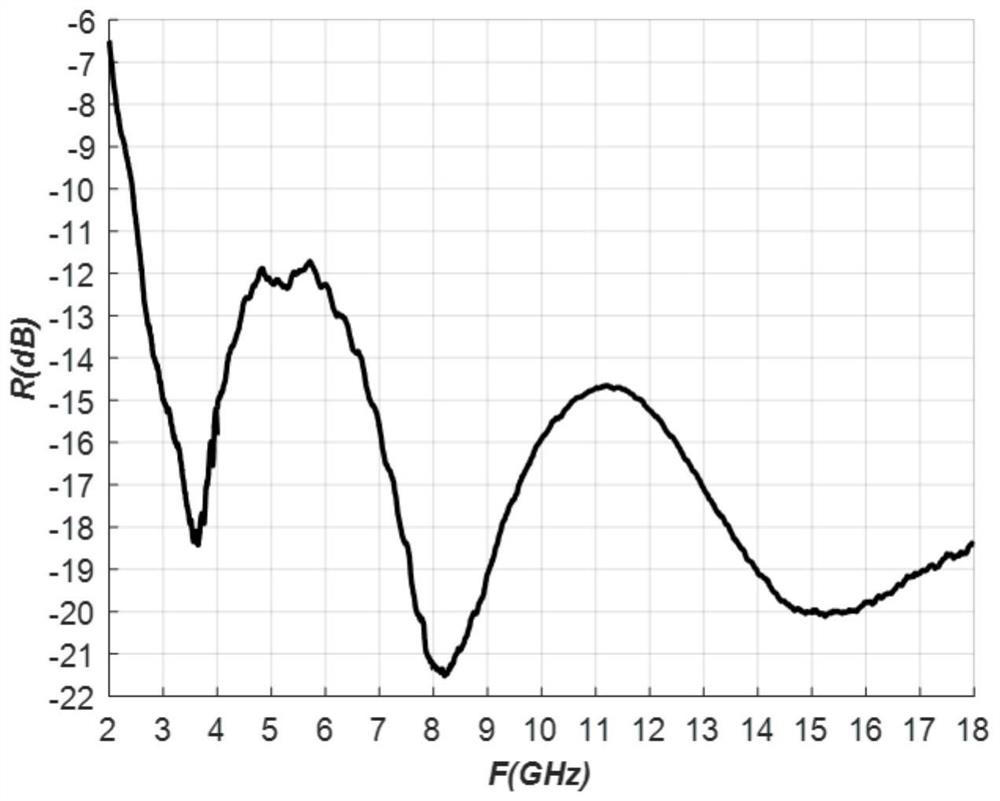

Image

Examples

preparation example Construction

[0040] The present invention also proposes a method for preparing a lightweight, flexible, flame-retardant broadband polyethylene-based wave-absorbing material as described above, including:

[0041] S1: Weigh the raw materials according to the ratio of parts by mass:

[0042]Low-density polyethylene (LDPE) 65-80 parts, linear low-density polyethylene (LLDPE) 35-20 parts, superconducting carbon black (HG-1P) 15-20 parts, chopped carbon fiber (C f ) 2 to 10 parts, ethylene-vinyl acetate (EVA) 5 to 10 parts, dicumyl peroxide (DCP) 0.5 to 1.5 parts, azodicarbonamide (AC) 4 to 6 parts, zinc stearate ( Zn-St) 1-3 parts, stearic acid (St) 1-3 parts and melamine cyanurate (MAC) 10-20 parts;

[0043] Chopped Carbon Fiber (C f ) In addition to being an absorber, it can also be used as a reinforcing material to enhance the mechanical properties of the finally prepared polyethylene-based wave-absorbing material.

[0044] S2: Mix low-density polyethylene, linear low-density polyethylen...

Embodiment example 1

[0058] This implementation case proposes a preparation method of a lightweight, flexible, flame-retardant and broadband polyethylene-based wave-absorbing material, including:

[0059] S1: Weigh the raw materials according to the ratio of parts by mass:

[0060] 70 parts of low-density polyethylene, 30 parts of linear low-density polyethylene, 18 parts of superconducting carbon black, 5 parts of chopped carbon fiber, 8 parts of ethylene-vinyl acetate, 1 part of dicumyl peroxide, and 5 parts of azodicarbonamide 1.5 parts of zinc stearate, 2 parts of stearic acid and 20 parts of melamine cyanurate;

[0061] S2: Mix low-density polyethylene, linear low-density polyethylene, superconducting carbon black, chopped carbon fiber and ethylene-vinyl acetate, and then melt and blend them on an internal mixer at a temperature of 110°C for 100 minutes to obtain a conductive blank material;

[0062] S3: Add dicumyl peroxide, azodicarbonamide, zinc stearate, stearic acid and melamine cyanur...

Embodiment example 2

[0071] This implementation case proposes a preparation method of a lightweight, flexible, flame-retardant and broadband polyethylene-based wave-absorbing material, including:

[0072] S1: Weigh the raw materials according to the ratio of parts by mass:

[0073] 65 parts of low-density polyethylene, 35 parts of linear low-density polyethylene, 18 parts of superconducting carbon black, 5 parts of chopped carbon fiber, 6 parts of ethylene-vinyl acetate, 1 part of dicumyl peroxide, and 5 parts of azodicarbonamide 1.5 parts of zinc stearate, 2 parts of stearic acid and 20 parts of melamine cyanurate;

[0074] S2: Mix low-density polyethylene, linear low-density polyethylene, superconducting carbon black, chopped carbon fiber and ethylene-vinyl acetate, and then melt and blend them on an internal mixer at a temperature of 110°C for 100 minutes to obtain a conductive blank material;

[0075] S3: Add dicumyl peroxide, azodicarbonamide, zinc stearate, stearic acid and melamine cyanur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average reflectance | aaaaa | aaaaa |

| Average reflectance | aaaaa | aaaaa |

| Average reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com