Multi-structure synergistically-enhanced thermal insulation aerogel/polymer composite material and preparation method thereof

A technology of composite materials and thermoplastic polymers, applied in the direction of conjugated synthetic polymer rayon, physical treatment, rayon manufacturing, etc., can solve the problem of low mechanical strength of airgel composite fibers and poor bonding between the skin layer and the core layer interface , affect the thermal insulation effect and other issues, to achieve the effect of enhancing the thermal insulation effect, increasing the airgel content, and improving the thermal insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The invention provides a method for preparing a thermal insulation airgel / polymer composite material synergistically reinforced by multiple structures, comprising the following steps:

[0030] S1. After uniformly mixing the first thermoplastic polymer and the airgel powder according to a preset mass ratio, a mixed material is obtained;

[0031] S2, using the mixed material obtained in step S1 as a skin layer, and using the second thermoplastic polymer as a core layer to prepare an airgel / polymer composite fiber with a skin-core structure;

[0032] S3. Perform plasma treatment on the airgel / polymer composite fiber obtained in step S2 to obtain an airgel / polymer composite fiber with a highly rough surface;

[0033] S4. Processing the airgel / polymer composite fiber with a highly rough surface obtained in step S3 into a non-woven fabric to obtain a thermal insulation airgel / polymer composite material synergistically reinforced by multiple structures.

[0034]In step S1, th...

Embodiment 1

[0041] This embodiment provides a method for preparing a thermal insulation airgel / polymer composite material synergistically reinforced by multiple structures, including the following steps:

[0042] S1. After uniformly mixing polypropylene and silica airgel powder according to the mass ratio of 70:30, a mixed material is obtained.

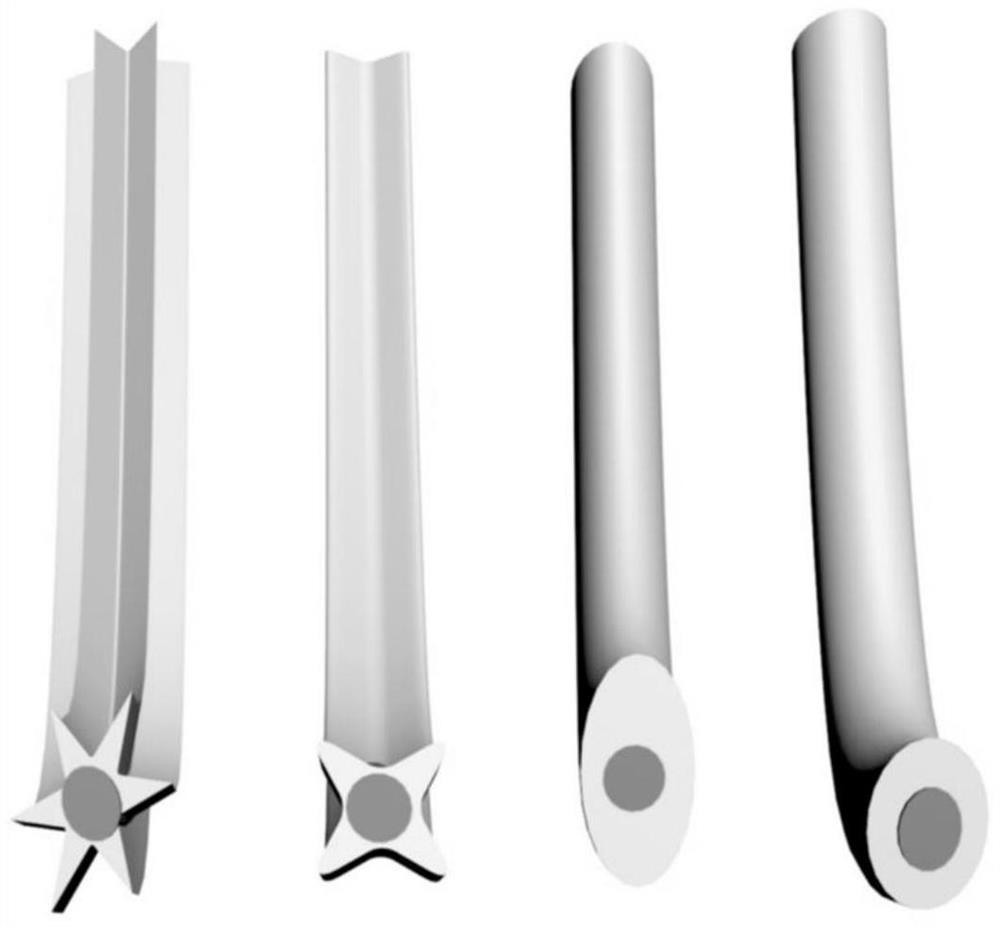

[0043] S2, using the mixed material obtained in step S1 as a cortex, and polyethylene as a core layer, controlling the mass ratio of the cortex to the core layer to be 1:1, and preparing a cross-section radially by a two-component sheath-core composite spinning machine The airgel / polymer composite fiber with the core-skin structure; the airgel / polymer composite fiber with the core-skin structure has a diameter of 100 μm and a detex number of 200 dtex.

[0044] S3, using air as the plasma treatment gas, setting the treatment power to 400W, and the treatment time to 30s, performing plasma treatment on the airgel / polymer composite fiber obtained in ...

Embodiment 2~7

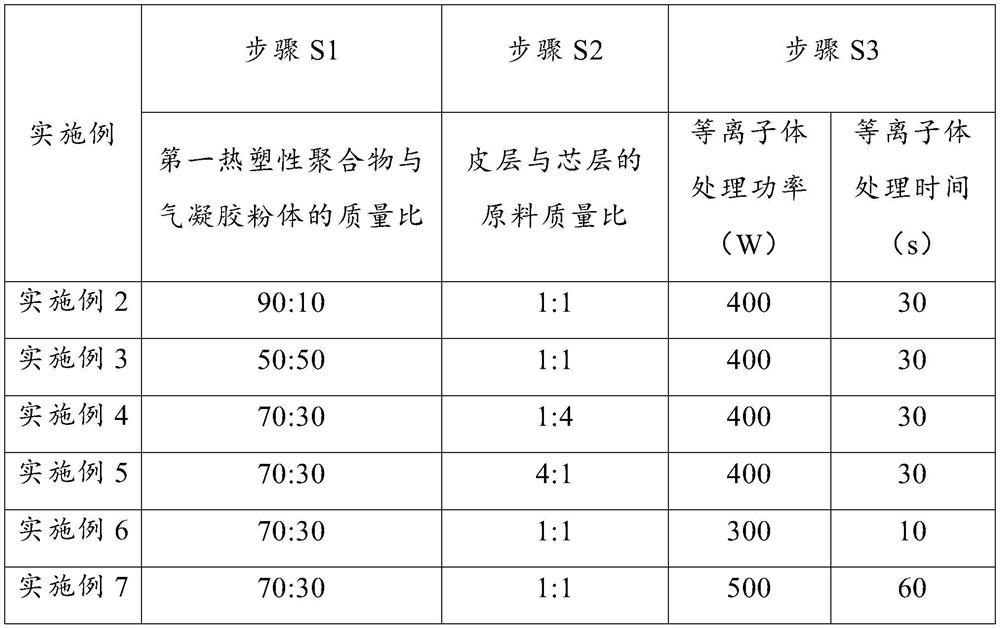

[0047] Examples 2 to 7 respectively provide a method for preparing a multi-component structure synergistically reinforced thermal insulation airgel / polymer composite material. Compared with Example 1, the difference is that the steps in Step S1 and Step S2 are changed. The mass ratio of raw materials or the plasma treatment parameters in step S3, and other steps are consistent with those in Embodiment 1, and will not be repeated here. The raw material mass ratios and process parameters corresponding to each embodiment are shown in Table 1.

[0048] Table 1 Embodiment 2~7 corresponding raw material mass ratio and process parameter

[0049]

[0050] The properties of the airgel / polymer composites prepared in Examples 1-7 were tested, and the results are shown in Table 2.

[0051] The performance of the airgel / polymer composite material that table 2 embodiment 1~7 prepares

[0052]

[0053]

[0054] It can be seen from Table 2 that the increase in the proportion of air...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com