A copper-zinc-tin-sulfur-based film precursor with a cyclic quantum well structure and its preparation method

A copper-zinc-tin-sulfur and precursor technology, which is applied in semiconductor devices, final product manufacturing, ion implantation and plating, etc., can solve problems such as difficulty in exporting photogenerated electron-holes, narrow single-phase region, and lowering battery operating voltage, etc. Achieve the effect of solving the overall element ratio imbalance, stable growth rate and reducing diffusion length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

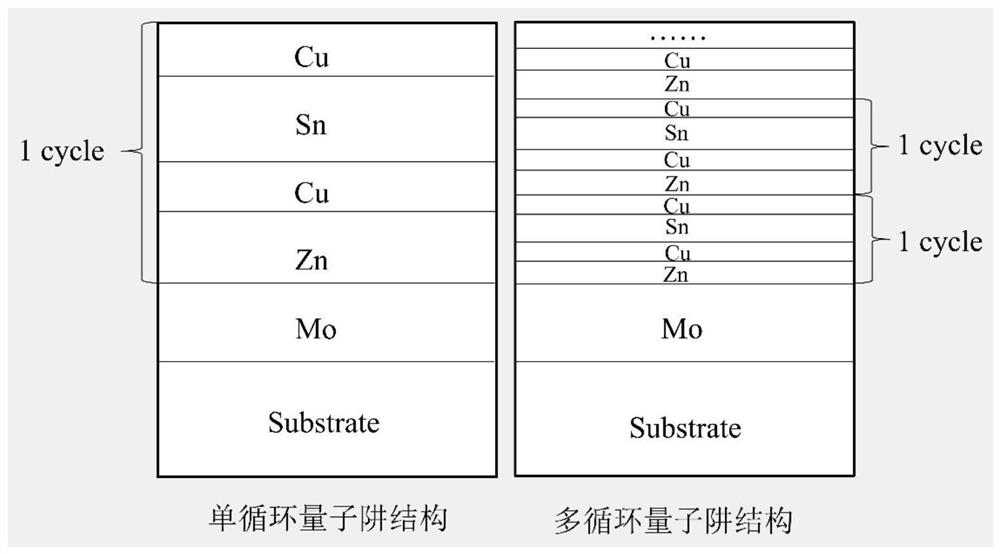

[0036] The present invention provides a kind of preparation method of the copper-zinc-tin-sulfur-based film precursor with cyclic quantum well structure, in some embodiments, the preparation method comprises the following steps:

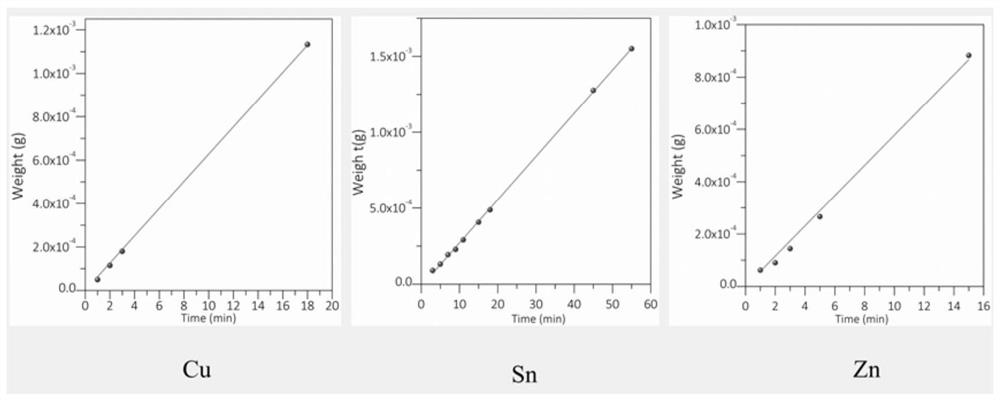

[0037] (1) Weigh and record the quality of the substrate, repeat 5 times, and take the average value;

[0038] (2) Fix the sputtering parameters of each growth source, grow a separate layer of precursor growth source layer on the substrate, obtain the precursor sample, weigh and record the quality of the precursor sample, repeat 5 times, and take the average value;

[0039] (3) Calculate the mass difference between the substrate and the precursor sample, adjust the growth time, and use the mass difference obtained at different growth times to convert the molar mass to obtain the relationship between the growth rate of the precursor growth source and the growth time;

[0040] (4) On the basis of obtaining the relationship between the growth rate and t...

Embodiment 1

[0045] In order to verify the effectiveness of the preparation method of the copper-zinc-tin-sulfur-based thin film precursor provided by the present invention, this embodiment constructs a precursor quantum well-like structure of one cycle. Specifically include the following steps:

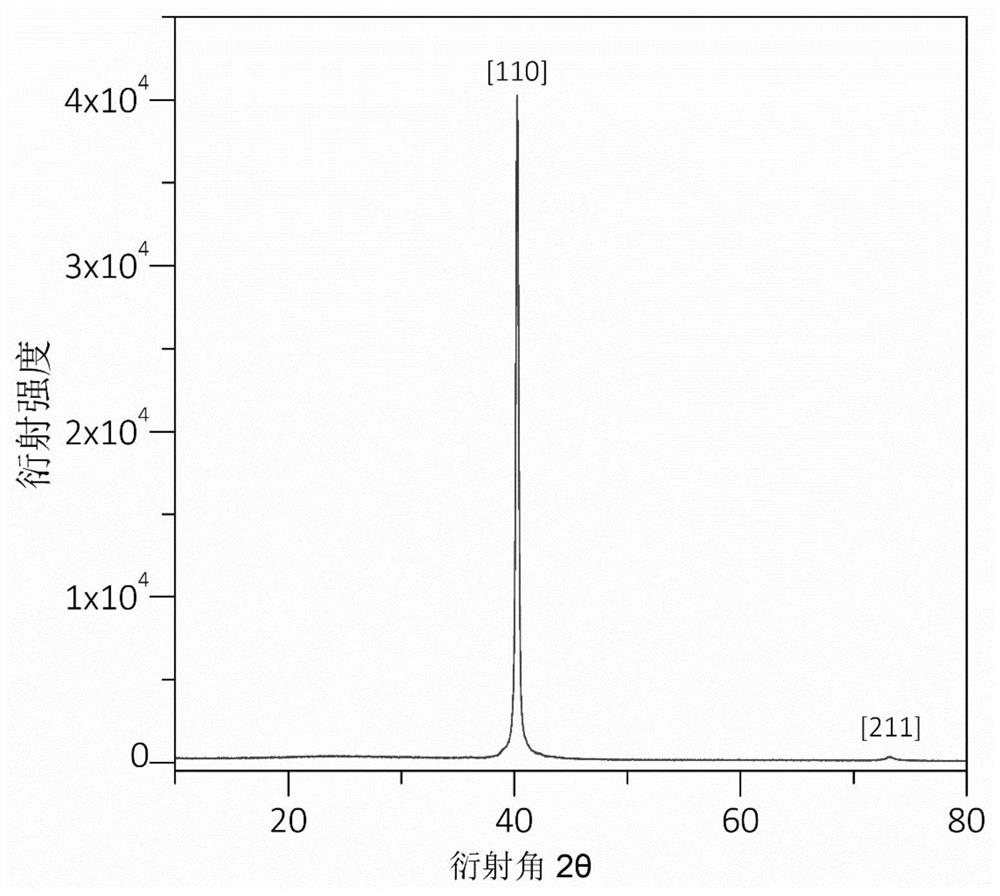

[0046] 1. Determine the relationship between the growth rate, film thickness and growth time of each precursor growth source:

[0047] The first step: first weigh the quality of five batches of soda-lime glass substrates, repeat 5 times and record, and take the average value; use magnetron sputtering equipment to sputter on each batch of soda-lime glass substrates The growth source of the zinc layer is the precursor growth source, the zinc growth source is a high-purity zinc metal target (99.99%), the power supply is a radio frequency power supply, the power is 100W, the air pressure is 0.3Pa, and the sputtering time of each batch of substrates is 1 and 2 respectively. , 3, 5 and 15 minutes, wei...

Embodiment 2

[0057] In order to verify the effectiveness of the preparation method of the copper-zinc-tin-sulfur-based thin film precursor provided by the present invention, this embodiment constructs 3 cycles of the precursor quantum well structure. Specifically include the following steps:

[0058] 1. Determine the relationship between the growth rate, film thickness and growth time of each precursor growth source:

[0059] The first step: first weigh the quality of five batches of soda-lime glass substrates, repeat 5 times and record, and take the average value; use magnetron sputtering equipment to sputter on each batch of soda-lime glass substrates The growth source of the zinc layer is the precursor growth source, the zinc growth source is a high-purity zinc metal target (99.99%), the power supply is a radio frequency power supply, the power is 100W, the air pressure is 0.3Pa, and the sputtering time of each batch of substrates is 1 and 2 respectively. , 3, 5 and 15 minutes, weigh t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com