Copper metal-organic framework material based on metal copper and preparation method and application thereof

A technology of metal-organic frameworks and organic frameworks, applied in applications, chemical instruments and methods, and other chemical processes, can solve problems such as difficult removal and large molecular structure of sterols, and achieve small molecular structure, high cost, and high yield. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Example 1: A preparation method of a copper-based metal-organic framework material

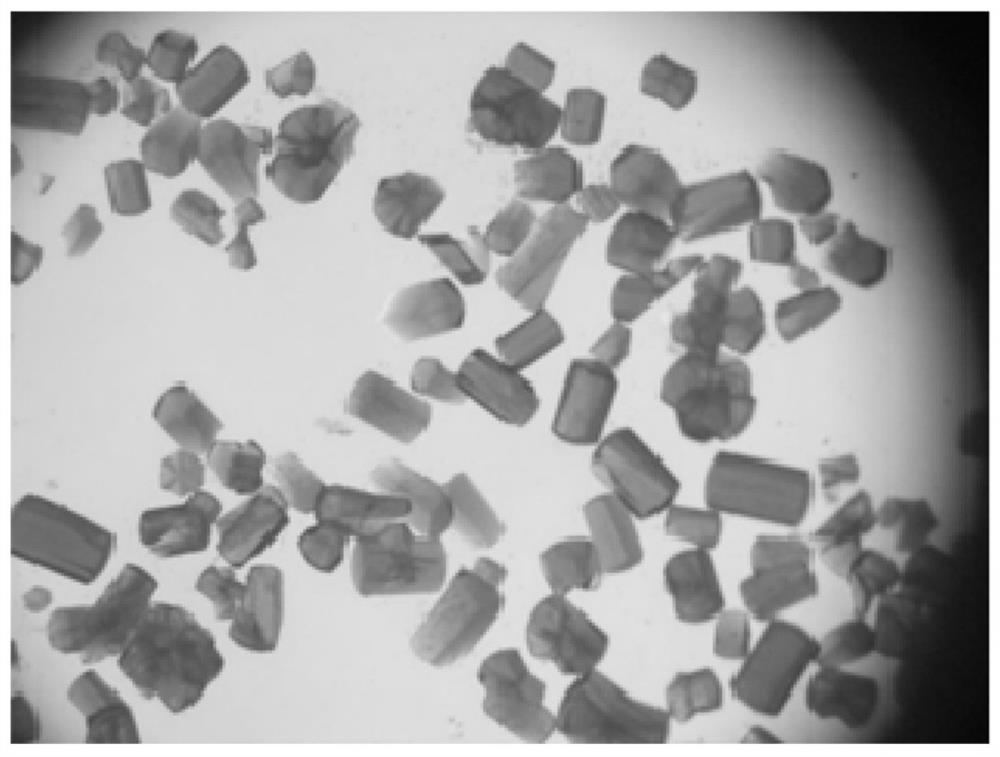

[0030] Add 10 mg (0.04 mmol) of benzimidazole diacid, 17 mg (0.1 mmol) of copper chloride dihydrate and 11 mg (0.1 mmol) of copper chloride dihydrate to a 23 mL polytetrafluoroethylene reactor at room temperature. ) l of sodium carbonate and 3 ml of N,N-dimethylformamide. After sealing, place it in an oven, raise the temperature to 100°C at a rate of 5°C per hour, react for 48 hours, and then gradually lower the temperature to room temperature at a rate of 2°C per hour. Then use 200 µL of dilute HCl with a concentration of 4 mol / L to adjust the pH, raise the temperature to 80 °C at a rate of 5 °C per hour, react for 48 hours, and then gradually lower the temperature to room temperature at a rate of 2 °C per hour. After washing with N,N-dimethylformamide solution for 3 to 4 times, green long crystals were filtered out; the yield was 80% based on copper.

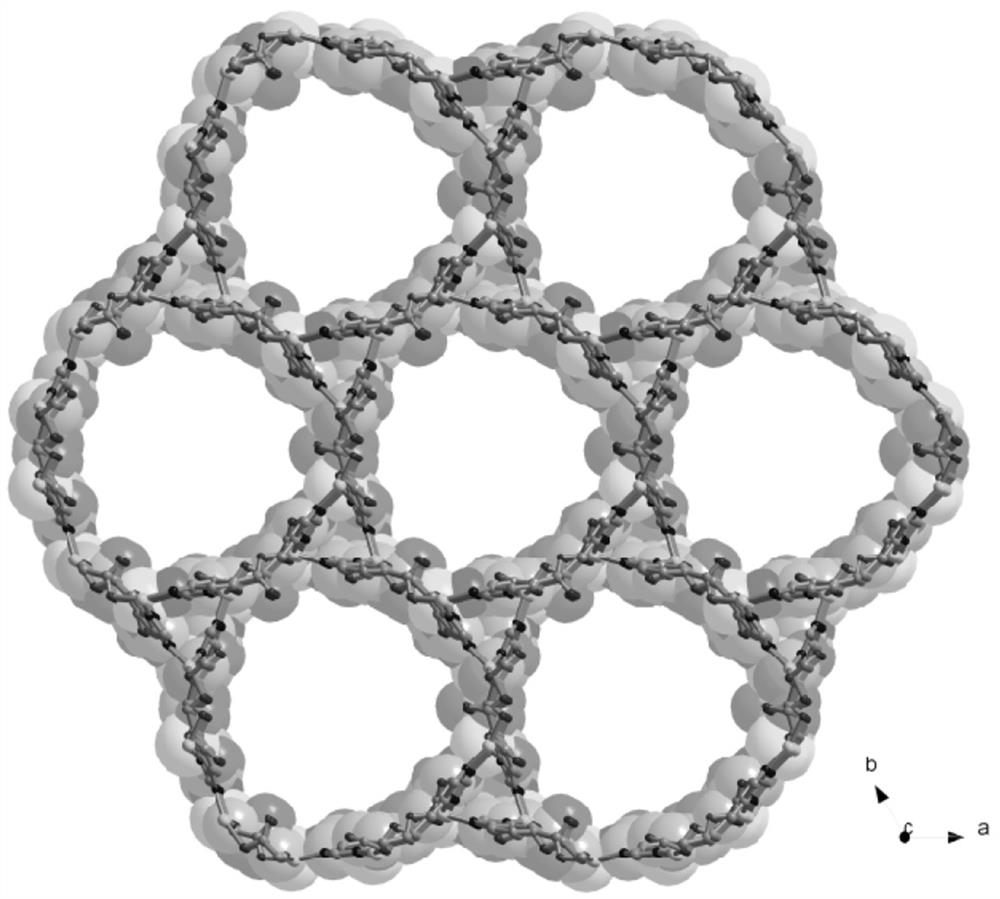

[0031] The crystal structure w...

Embodiment 2

[0033] Solvent-exchange 100 mg of the metal-organic framework material obtained with 20 mL of methanol. The methanol solvent was replaced once a day. After soaking for three days, the solvent was exchanged again with 20 mL of dichloromethane. Drying was carried out in a 60 degree oven for 24 hours. Then, it was activated under vacuum at 50°C for 24 hours to obtain the metal-organic framework material after removing the solvent.

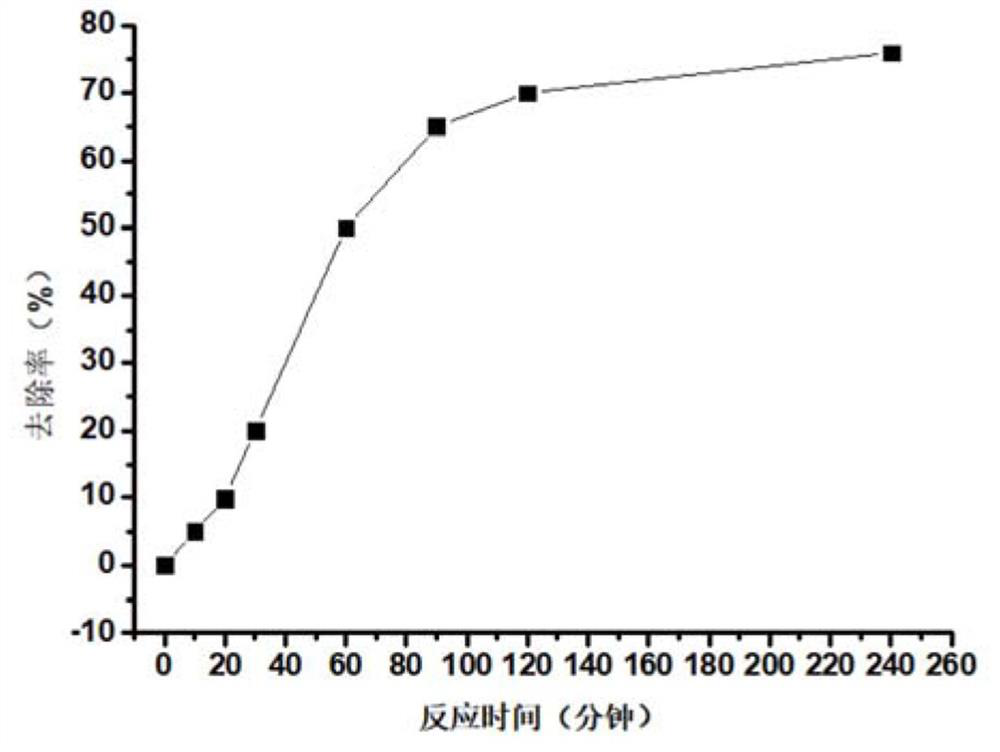

[0034]Then take 25 mg powder metal organic framework material and put it in a 50 mL round bottom flask, add 20 mg stigmasterol, 10 mL 95% ethanol, stir at room temperature for 10 min, 20 min, 30 min, 60 min, 90 min respectively , 120 min, 240 min. After filtration, the removal ability of metal-organic frameworks to stigmasterol at room temperature was tested by ferrophosphorus method, image 3 Show: this material is respectively 5%, 10%, 20%, 50%, 65%, 70% to the removal rate of stigmasterol in 10 min, 20 min, 30 min, 60 min, 90 min, 120min, 240min ...

Embodiment 3

[0035] Example 3: A preparation method of a copper-based metal organic framework material

[0036] At room temperature, add 10.2 mg (0.04 mmol) of benzimidazole diacid, 16.9 mg (0.1 mmol) of copper chloride dihydrate and 11.3 mg (0.1 mmol) to a 23 mL polytetrafluoroethylene reactor ) l of sodium carbonate and 3 ml of N,N-dimethylformamide. After sealing, place it in an oven, raise the temperature to 100°C at a rate of 5°C per hour, react for 48 hours, and then gradually lower the temperature to room temperature at a rate of 2°C per hour. Then use 200 µL of dilute HCl with a concentration of 4 mol / L to adjust the pH, raise the temperature to 80 °C at a rate of 5 °C per hour, react for 48 hours, and then gradually lower the temperature to room temperature at a rate of 2 °C per hour. Washed 4 times with N,N-dimethylformamide solution, and the green long crystals were filtered out; the yield was 83% based on copper.

[0037] The crystal structure was determined by a Supernova X-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com