Polymer dielectric elastomer as well as preparation method and application thereof

A technology of dielectric elastomers and polymers, applied in the direction of testing dielectric strength, measuring electricity, strength characteristics, etc., can solve the problems of low sensitivity and low dielectric constant of sensors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

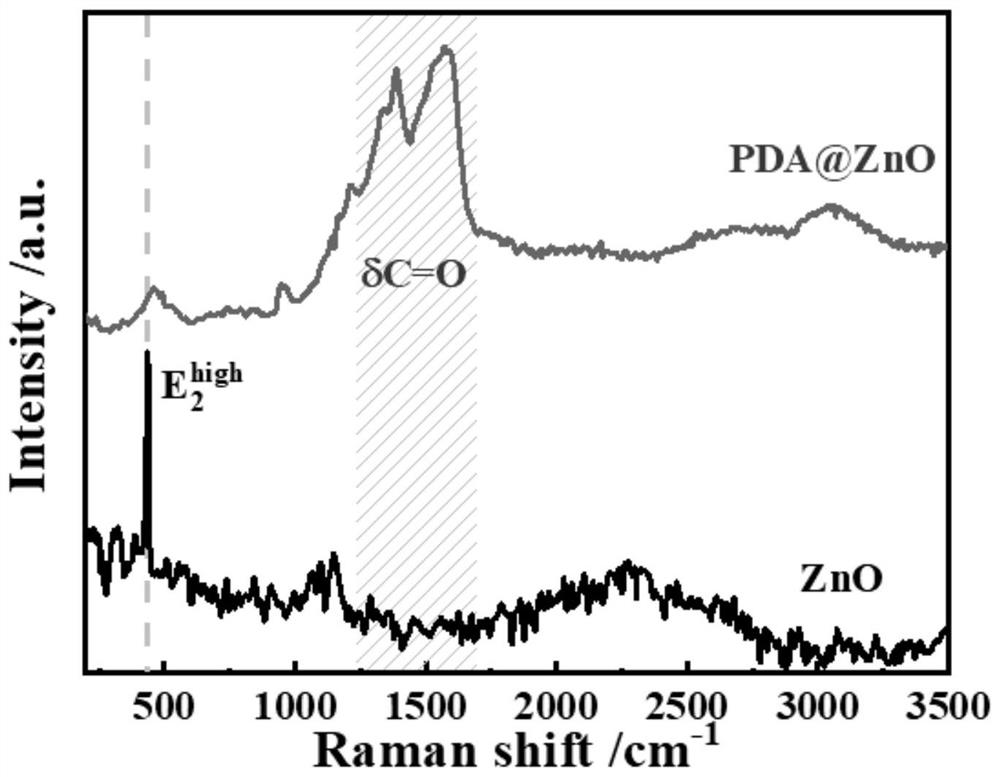

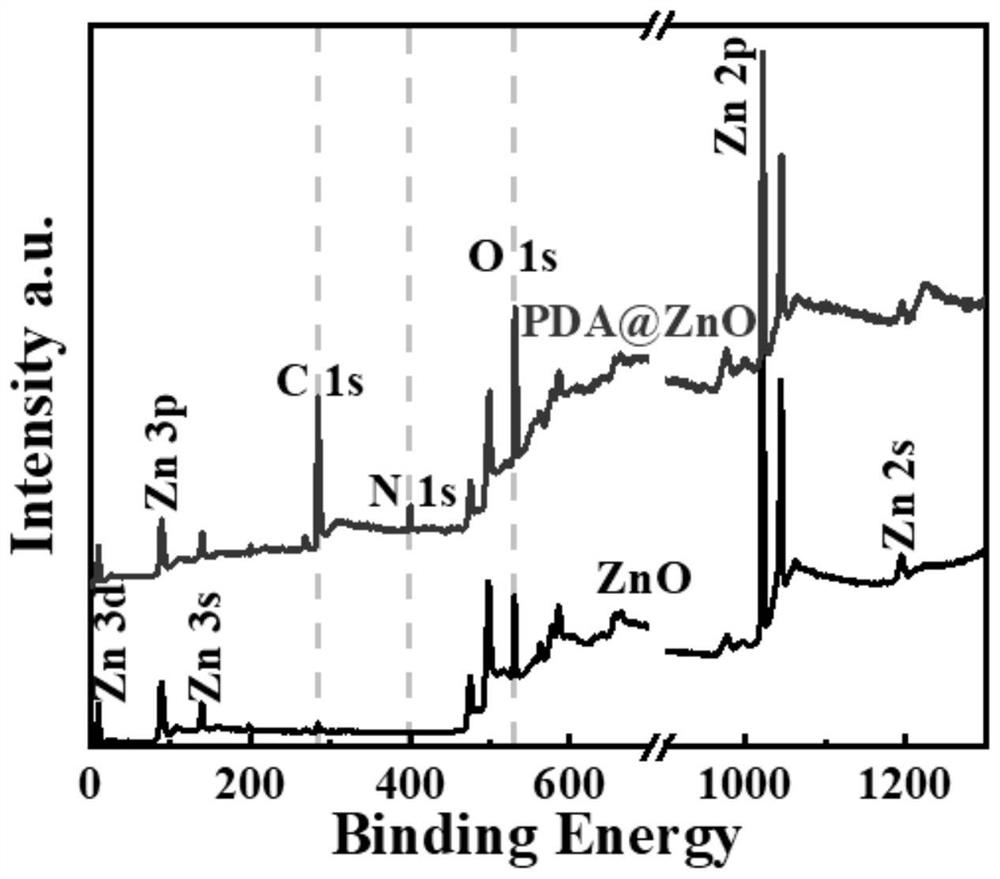

[0034] Preparation of PDA@ZnO

[0035] 3 g of ZnO nanoparticles were ultrasonically dispersed in 400 mL of Tris-HCl (0.01M, PH=8.5) solution, and then poured into a clean 500 mL round bottom flask. Weigh 1.5 g of dopamine hydrochloride, and slowly add it into the round bottom flask under continuous stirring. After bubbling oxygen into the round bottom flask for three minutes, it was sealed with a rubber stopper. After the reaction lasted for 24 h, it was centrifuged and washed with deionized water, and finally dried in a vacuum oven at 60 °C for 24 h to obtain PDA@ZnO nanoparticles.

Embodiment 2

[0037] Preparation of EVA membrane (film 1)

[0038] Take 2 g of EVA and dissolve it in 20 mL of tetrahydrofuran solvent. After stirring continuously at room temperature for 1 h, add 4 g of di-n-butyl adipate, and then continue stirring for 1 h. Finally, it was poured into a glass petri dish and dried in a vacuum oven at 60 °C for 24 h to obtain an EVA film (film 1).

Embodiment 3

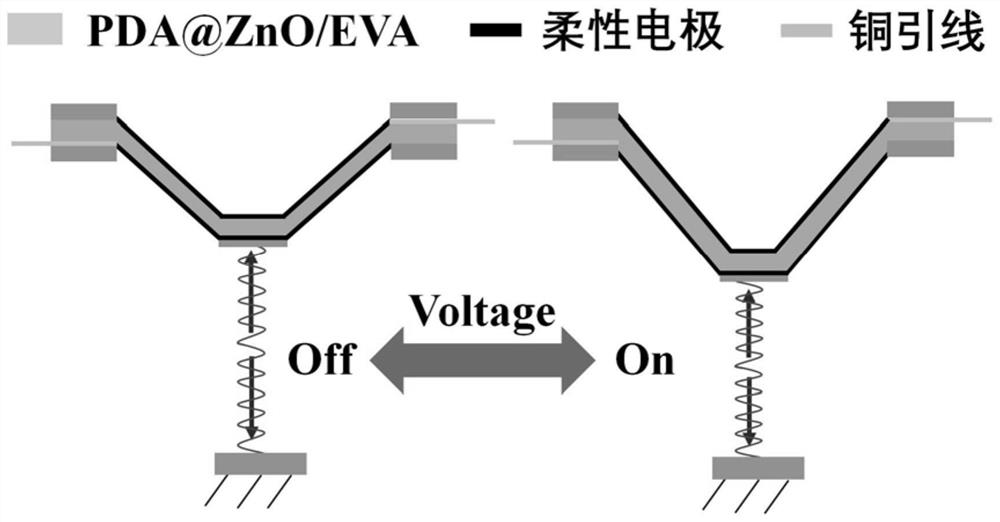

[0040]Preparation of PDA@ZnO / EVA Polymer Dielectric Elastomer (Film 2)

[0041] 0.32 g of PDA@ZnO nanoparticles were ultrasonically dispersed in 20 mL of tetrahydrofuran solvent, and then 2 g of EVA was added. After stirring continuously at room temperature for 1 h, 4 g of di-n-butyl adipate was added, and stirring was continued for another 1 h. Finally, it was poured into a glass petri dish and dried in a vacuum oven at 60 °C for 24 h to obtain a PDA@ZnO / EVA polymer dielectric elastomer (film 1).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com