High-temperature-resistant sealing rubber strip for vacuum forming

A sealing strip and vacuum forming technology, applied in the direction of adhesives, non-polymer adhesive additives, rosin adhesives, etc., can solve the problems of product pollution, detachment from the mold, melting and flowing, etc., and achieve enhanced thermal and oxygen aging resistance , excellent high temperature resistance, uniform distribution of components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

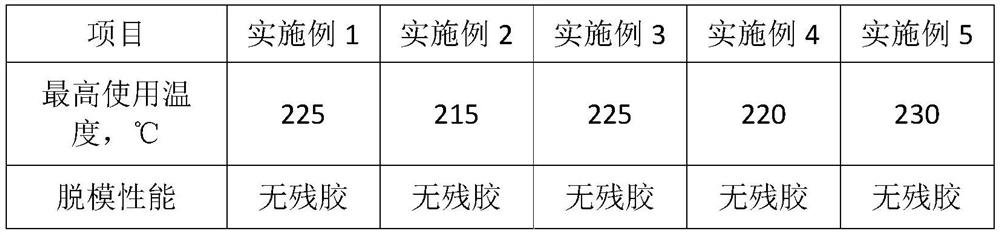

Examples

Embodiment 1

[0032] 60 parts of butyl rubber, 20 parts of brominated butyl rubber, 50 parts of rosin resin, 100 parts of polyisobutylene, 180 parts of light calcium carbonate, 20 parts of kaolin, 20 parts of talcum powder, 201 brominated hydroxymethyl tert-octylphenolic novolac 6 parts of resin, 2 parts of zinc oxide, 1 part of RD antioxidant, 1 part of phthalocyanine green.

[0033] The preparation method is as follows: each component is masticated by an open mill, kneaded by a kneader, and extruded by an extruder.

Embodiment 2

[0035] 70 parts of butyl rubber, 10 parts of bromobutyl rubber, 30 parts of rosin resin, 120 parts of polyisobutylene, 150 parts of heavy calcium carbonate, 50 parts of kaolin, 50 parts of talc, 2,6-hydroxydimethyl-4 - 15 parts of chlorophenol resin, 2 parts of stannous chloride, 2 parts of NBC antioxidant, 30 parts of iron red.

[0036] The preparation method is as follows: each component is masticated by an open mill, kneaded by a kneader, and extruded by an extruder.

Embodiment 3

[0038] 50 parts of butyl rubber, 30 parts of brominated butyl rubber, 30 parts of rosin resin, 120 parts of polyisobutylene, 180 parts of nano calcium carbonate, 30 parts of kaolin, 20 parts of barium sulfate, 201 brominated hydroxymethyl tert-octyl phenolic resin 10 parts, 5 parts of ferric chloride, 5 parts of 1010 antioxidant, 5 parts of carbon black.

[0039] The preparation method is as follows: each component is masticated by an open mill, kneaded by a kneader, and extruded by an extruder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com