Iodine element double-site doped perovskite catalyst material and preparation method thereof

A perovskite and catalyst technology, which is applied in the field of iodine element double-site doped perovskite catalyst materials and its preparation, can solve the problems of inability to improve OER performance, achieve excellent OER performance and stability, and improve performance significantly. obvious effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

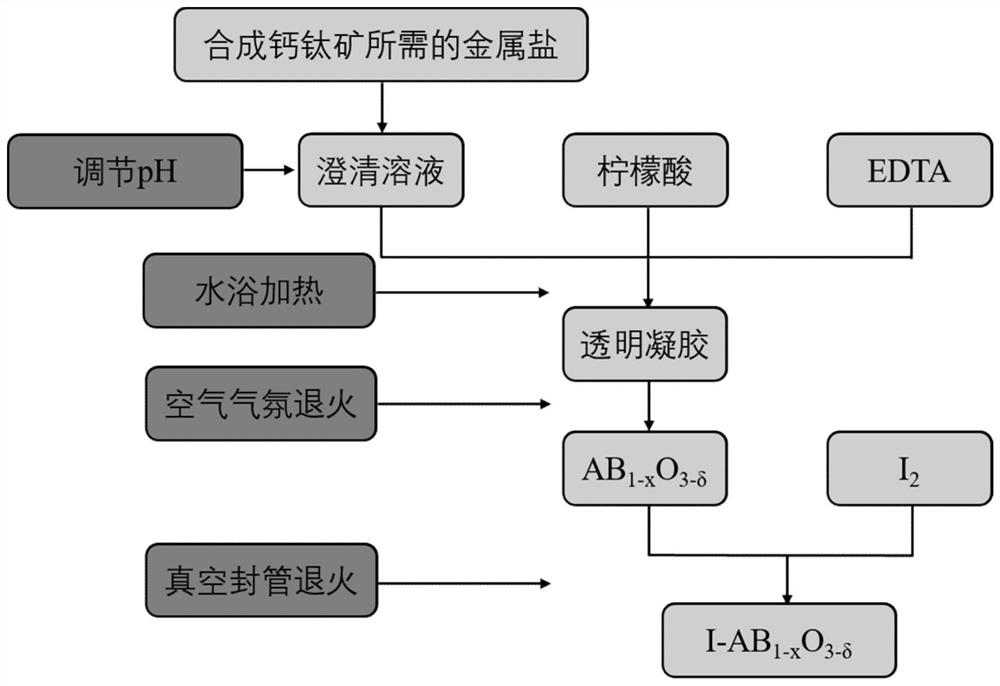

[0032] combine figure 1 , the preparation method of a kind of iodine element two-site doped perovskite electrocatalyst of the present invention, comprises the steps:

[0033] Step 1: Preparation of gel: Weigh the metal salt required for the synthesis of perovskite in a beaker in a certain proportion, add a certain amount of ethylenediaminetetraacetic acid and citric acid, adjust the pH value with ammonia water, and stir the mixed solution to obtain a transparent liquid. The liquid was stirred and heated at a temperature of 90-95 °C, and finally a transparent gel was obtained.

[0034] Step 2: Preparation of perovskite: anneal the gel prepared in step 1 in the air environment, the annealing temperature is 900 ℃, 2~3 h, the heating rate is 2 ℃ / min, and named as AB 1-x o 3-δ .

[0035] Step 3: Preparation of iodine element double-site doped perovskite: AB prepared in step 2 1-x o 3-δ Perovskite and I 2 Vacuum-sealed annealing at a mass ratio of 15:1, the annealing temperatu...

Embodiment 1

[0040] Step 1: Weigh 0.2613 g (1 mmol) barium nitrate, 0.2237 g (1 mmol) strontium acetate, 0.4190 g (1.44 mmol) cobalt nitrate and 0.1454 g (0.36 mmol) ferric nitrate in a beaker, add 30 ml deionized water Stir until dissolved, then add 1.168 g (4 mmol) ethylenediaminetetraacetic acid and 0.84 g (4 mmol) citric acid and adjust the pH to ~8 with ammonia water to obtain a purple transparent solution. Heated in a water bath with stirring at 95 °C for 6 h until a transparent purple gel was formed.

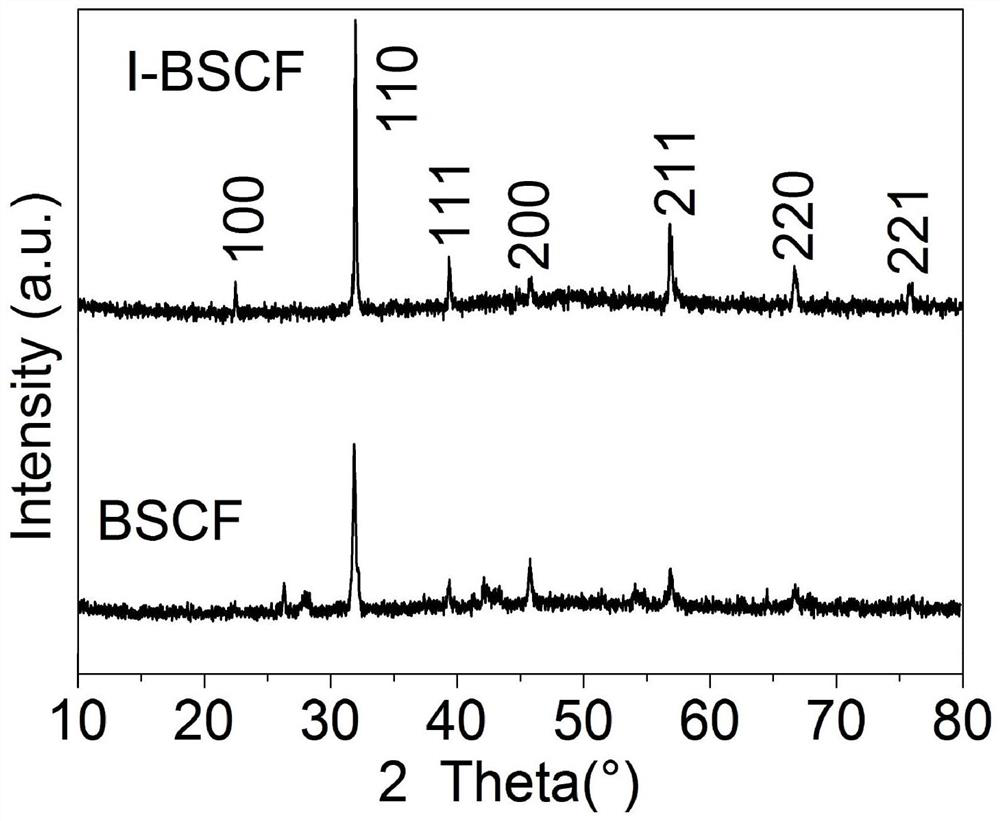

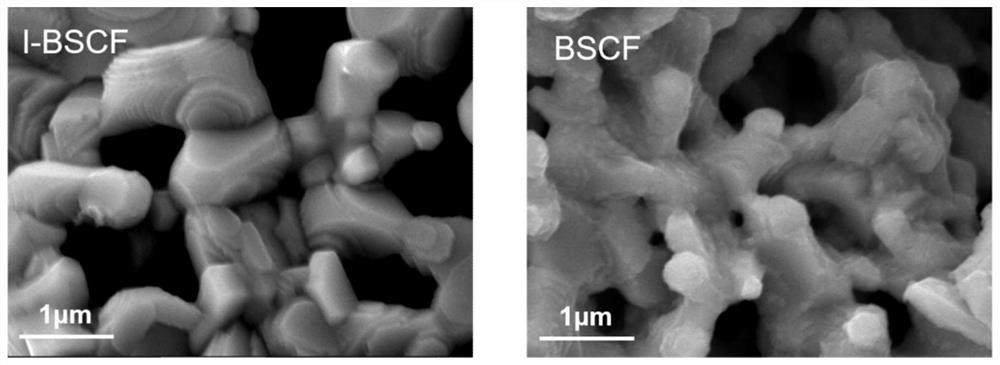

[0041] Step 2: Transfer the transparent purple gel to a crucible, and calcinate in an air atmosphere in a muffle furnace at a high temperature at a temperature of 900 °C for 2 h, and the heating rate of the muffle furnace is 2 °C / min to obtain a BSCF perovskite with B-site defects mine.

[0042] Step 3: Combine the obtained BSCF perovskite with I 2 Put it into a quartz tube with a mass ratio of 15:1, vacuum seal the quartz tube, and transfer it to a muffle furnace for annealing treatm...

Embodiment 2

[0046] Carry out with reference to the step in embodiment 1. In step 1, weigh strontium acetate and cobalt nitrate in a beaker according to a certain proportion, add a certain amount of ethylenediaminetetraacetic acid and citric acid, adjust the pH value to ~8 with ammonia water, and stir the mixed solution to obtain a purple transparent liquid. The liquid was stirred and heated at a temperature of 90-95 °C, and finally a transparent purple gel was obtained. Combine the obtained SCO perovskite with I 2 Put it into a quartz tube with a mass ratio of 15:1, vacuum seal the quartz tube, and transfer it to a muffle furnace for annealing treatment. The annealing temperature is 1000 °C for 5 h, and the heating rate is 2 °C / min. The resulting sample was designated I-SCO. Figure 7 XPS data of iodine elements in SCO and I-SCO perovskites are presented, Figure 8 The LSV diagrams of the iodine element double-site doped perovskite electrocatalysts SCO and I-SCO at 1 M KOH are shown, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com