Laminated lithium metal battery negative electrode material, preparation method thereof and lithium metal secondary battery

A technology for lithium metal batteries and negative electrode materials, which is applied in secondary batteries, electrode manufacturing, battery electrodes, etc., can solve the problems of difficult thickness control, insufficient SEI stability, complex modification layer process, etc., and achieves high industrial application prospects that are not easy to fall off , to promote the effect of uniform deposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

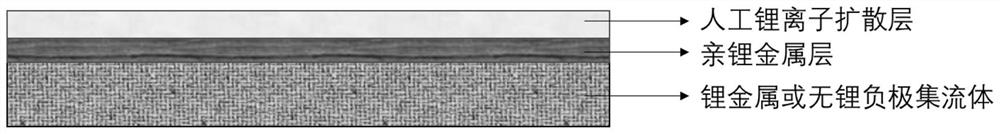

[0027] Its preparation method mainly comprises the following steps:

[0028] 1) Metal lithium or lithium-free negative electrode current collectors are prepared by physical vapor deposition or chemical vapor deposition methods to prepare lithium-friendly metal layers;

[0029] Specifically, the lithium metal includes: any one of lithium sheet, lithium strip, lithium foil, lithium block or lithium wire.

[0030] Specifically, the lithium-free negative electrode current collector includes: at least one of copper foil, nickel foil, stainless steel foil, iron foil, carbon cloth, carbon paper, graphene film, carbon nanotube film or carbon fiber film.

[0031] Specifically, the lithium-friendly metal layer is at least one of silicon, magnesium, copper, silver, beryllium, zinc, aluminum, gold or boron; the thickness of the artificial lithium ion diffusion layer is 5nm-5μm.

[0032] 2) preparing an artificial lithium ion diffusion layer on the surface of the lithium-friendly metal la...

Embodiment 1

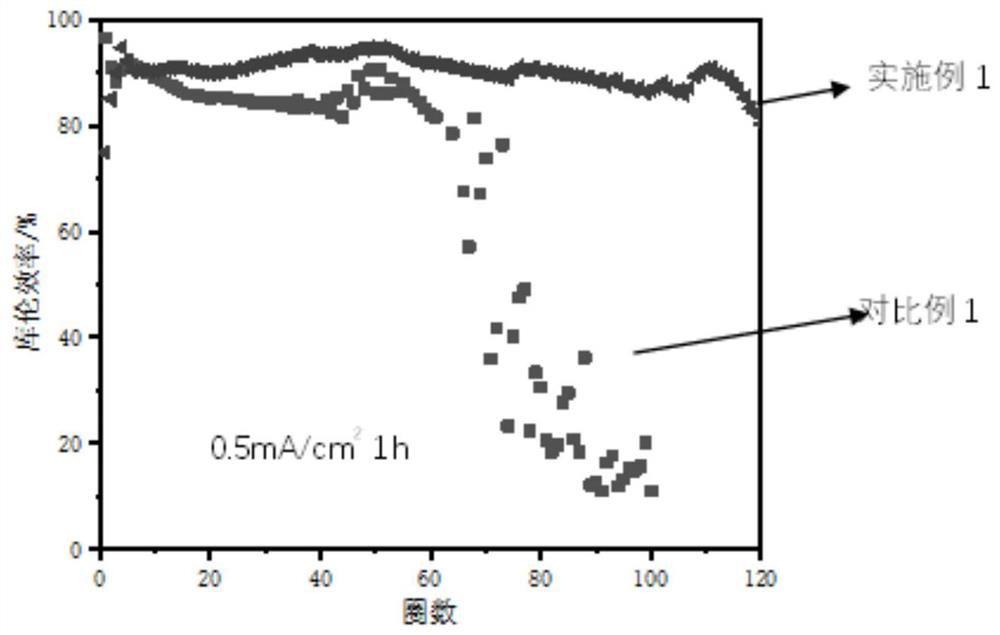

[0036] A copper foil with a thickness of 12 μm was selected as the substrate, and a metal silver layer with a thickness of 100 nm was deposited on its surface as a lithium-friendly metal layer by DC magnetron sputtering. Then, a LiPON layer with a thickness of 500 nm was deposited on the surface of the metal silver layer by radio frequency magnetron sputtering as an artificial lithium ion diffusion layer to obtain a negative electrode of a laminated lithium metal battery.

[0037] The laminated electrode punched sheet obtained above, Celgard2400 diaphragm, lithium sheet, lithium ion electrolyte, the composition is 1MLiTFSI 1,3-dioxolane DOL / ethylene glycol dimethyl ether DME, assembled into a button battery. Test using 0.5mA / cm 2 current density, surface capacity of 0.5mAh / cm 2 .

[0038] see results figure 2 , the cycle efficiency of the stacked lithium metal battery negative electrode is stable at more than 90% within 100 cycles, while the coulombic efficiency of the pur...

Embodiment 2

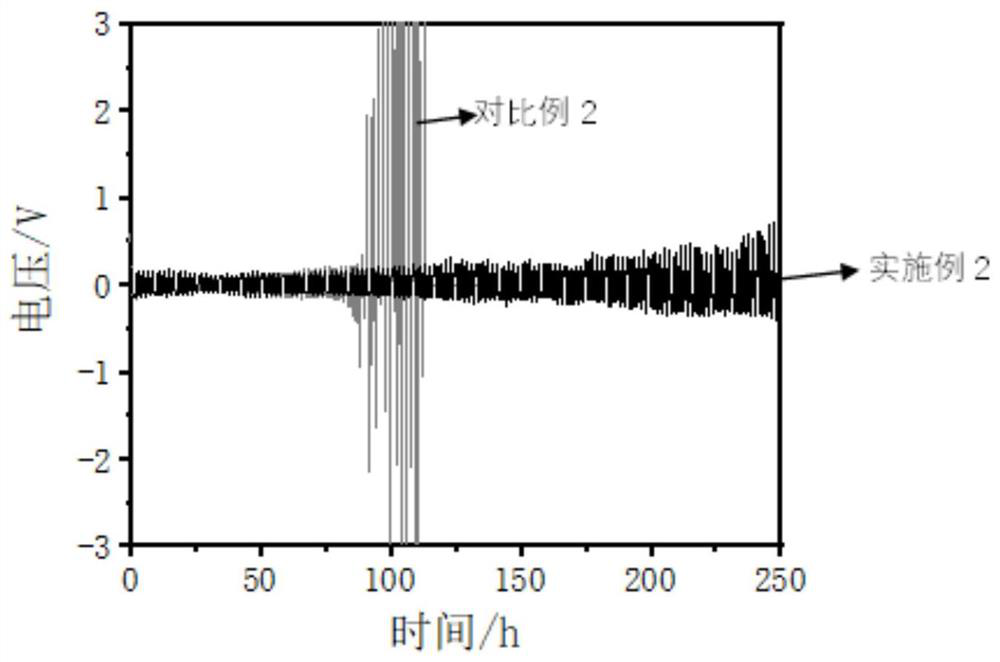

[0042] A metal lithium sheet with a thickness of 400 μm was selected as a substrate, and a metal silver layer with a thickness of 100 nm was deposited on its surface by DC magnetron sputtering as a lithium-friendly metal layer. Then, a LiPON layer with a thickness of 500 nm was deposited on the surface of the metal silver layer by radio frequency magnetron sputtering as an artificial lithium ion diffusion layer to obtain a negative electrode of a laminated lithium metal battery.

[0043]The laminated electrode obtained above, Celgard2400 diaphragm, lithium sheet, lithium ion electrolyte, the composition is 1MLiTFSI 1,3-dioxolane DOL / ethylene glycol dimethyl ether DME, assembled into a button battery. Tested using 5mA / cm 2 current density, surface capacity of 5mAh / cm 2 .

[0044] see results image 3 , the pure metal lithium negative electrode only cycles for nearly 100 hours, while the stacked metal lithium negative electrode of lithium phosphorus oxygen nitrogen / silver / lit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com