Niobium-doped lithium titanate material, preparation method thereof and lithium battery

A lithium titanate, slurry technology, applied in titanate, secondary batteries, battery electrodes, etc., can solve the problems of poor low temperature cycle performance, improve low temperature cycle performance, increase wetting area, and enrich pore structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] In another typical embodiment of the present application, a method for preparing any of the above-mentioned niobium-doped lithium titanate materials is provided, the preparation method comprising: step S1, combining lithium source, titanium source, niobium source Mixing with a solvent to form a mixed slurry; step S2, ultrasonically treating the mixed slurry to obtain a dispersed slurry; step S3, wet grinding the dispersed slurry to obtain a wet-milled slurry; step S4, performing Spray drying to obtain microspheres; step S5, roasting the microspheres in an oxygen-containing atmosphere to obtain a lithium titanate material, wherein the lithium source is lithium hydroxide, the titanium source is titanium dioxide or titanium hydroxide, and the niobium source is five Niobium oxide is roasted at a temperature of 600-900°C for 3-12 hours.

[0028] Weigh each lithium source, titanium source, and niobium source according to the set ratio, and mix the raw materials of each elemen...

Embodiment 1

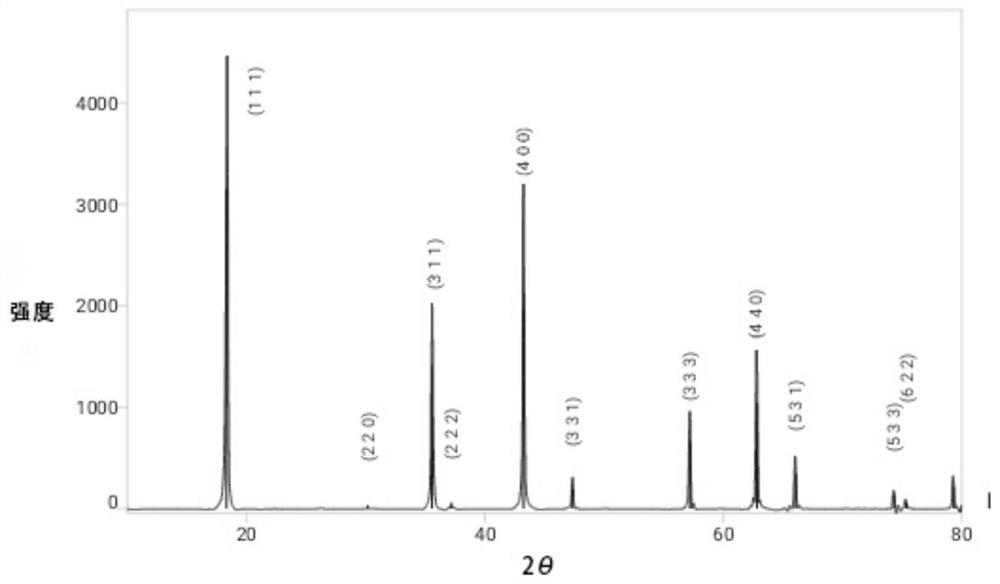

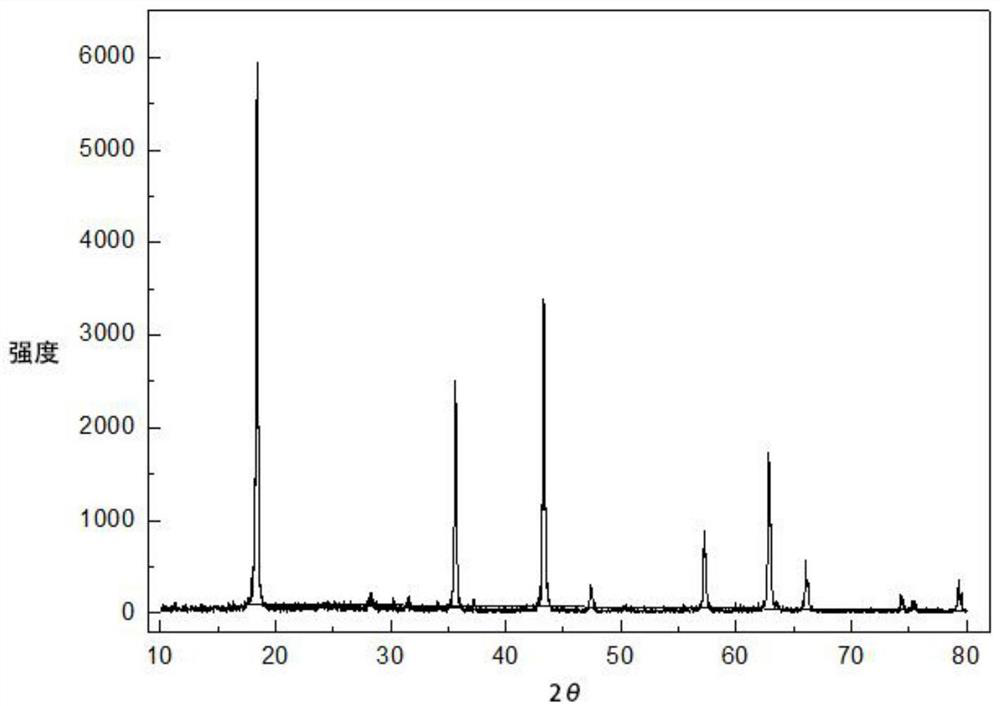

[0042] Preparation of Nb element doped lithium titanate:

[0043] Weigh lithium hydroxide, titanium dioxide and niobium pentoxide according to the molar ratio of lithium, titanium and niobium 4:4.95:0.05; mix lithium hydroxide, titanium dioxide and deionized water, stir for 0.5h, then add niobium pentoxide, stir for 0.5 ~1h, make mixed slurry, the solid content of mixed slurry is 20%; This mixed slurry utilizes the ultrasonic power of 0.6kw to process 40min, obtains dispersed slurry; This dispersed slurry is wetted on ball mill The grinding ball is zirconium ball, the filling rate of wet grinding is 70-80%, the rotating speed is 3000r / min, the pressure is 1.0bar, the grinding time is 5h, and the wet grinding slurry is obtained. The solid particle size in the wet grinding slurry is Between 30-70nm; the prepared wet grinding slurry is exported and placed in a stirrer for half an hour. The wet grinding slurry that has been placed is subjected to a spray drying process. The condi...

Embodiment 2

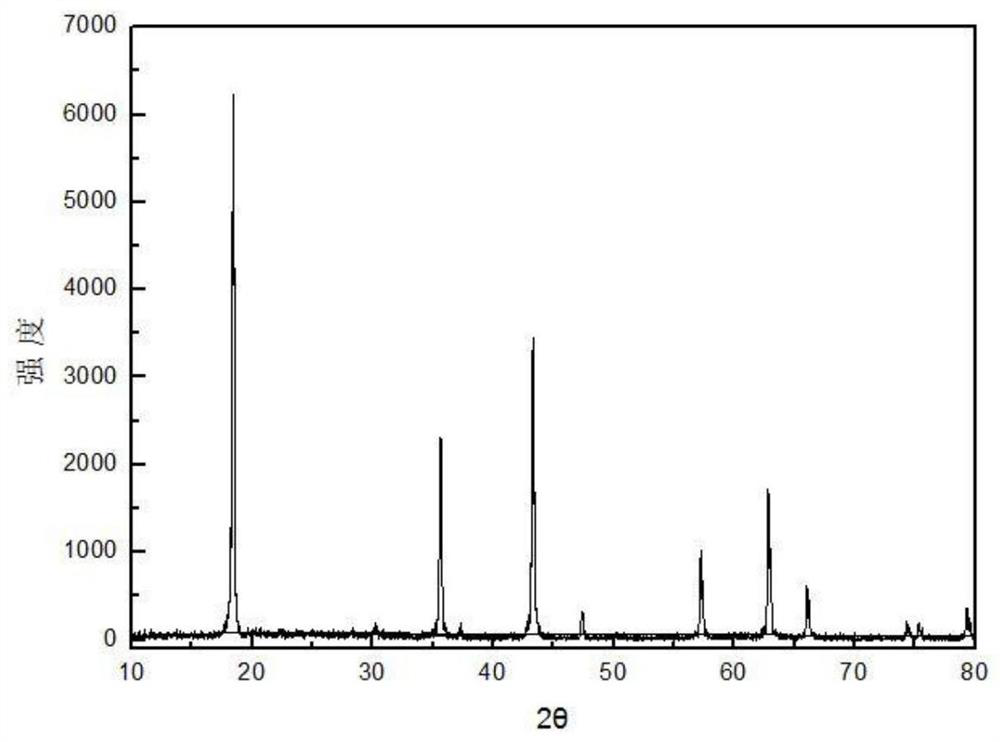

[0045] Preparation of Nb element doped lithium titanate:

[0046] Weigh lithium hydroxide, titanium dioxide and niobium pentoxide according to the molar ratio of lithium, titanium and niobium 4:4.85:0.15; mix lithium hydroxide, titanium dioxide and deionized water, stir for 0.5h, then add niobium pentoxide, stir for 0.5 ~1h, make mixed slurry, the solid content of mixed slurry is 20%; This mixed slurry utilizes the ultrasonic power of 0.6kw to process 40min, obtains dispersed slurry; This dispersed slurry is wetted on ball mill The grinding ball is zirconium ball, the filling rate of wet grinding is 70-80%, the rotating speed is 3000r / min, the pressure is 1.0bar, the grinding time is 5h, and the wet grinding slurry is obtained. The solid particle size in the wet grinding slurry is Between 30-70nm; the prepared wet grinding slurry is exported and placed in a stirrer for half an hour. The wet grinding slurry that has been placed is subjected to a spray drying process. The condi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com