Composite porous microspheres and preparation method and application thereof

A technology of porous microspheres and chitosan, which is applied in the field of medicine, can solve problems such as microspheres that cannot be prepared for vascular embolism, and achieve the effect of being suitable for large-scale preparation, easy to repeat, and uniform in shape and size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

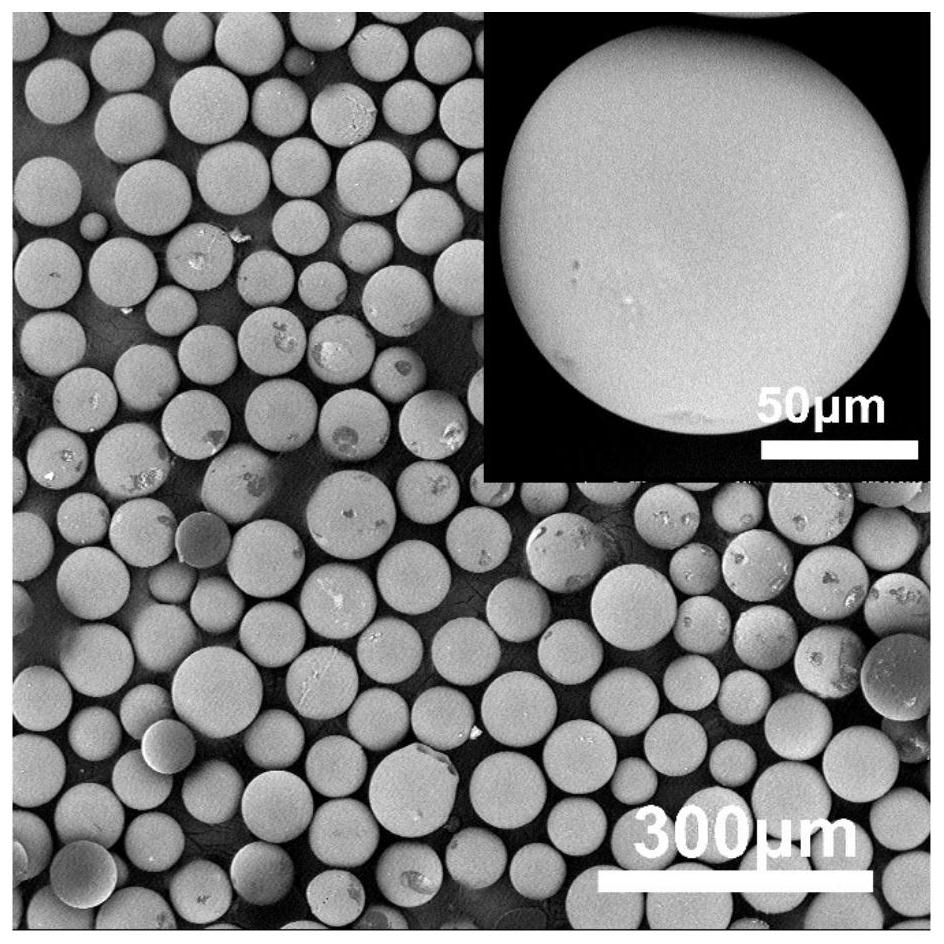

[0087] (1) Dissolve 1g chitosan oligosaccharide in 25mL DMF, add 5mL chlorosulfonic acid, adjust the pH to 7.0 after reacting at 70°C for 4h, wash with deionized water and ethanol three times respectively, centrifuge and dialyze with 2500Da dialysis bag for 48h, then vacuum Freeze-drying to obtain sulfonated chitosan;

[0088] (2) Weigh 0.625g chitosan, 0.1875g sulfonated chitosan and 0.1875g sodium alginate respectively, and prepare a mixed aqueous solution with a mass fraction of 1%;

[0089] (3) Contain 4.8g Span 80 and 0.2g Tween 20 in 100mL petroleum ether for preparing emulsifier solution;

[0090] (4) Weigh 0.08gCaCl 2 , prepared into a 5mL aqueous solution. Add 10mL chitosan / sulfonated chitooligosaccharide / sodium alginate aqueous solution drop by drop into the organic solvent containing emulsifier through a syringe pump, stir evenly to form an emulsion, the rotation speed is 520rpm; after stirring at a constant speed for 3h, add the prepared CaCl 2 Aqueous solution,...

Embodiment 2

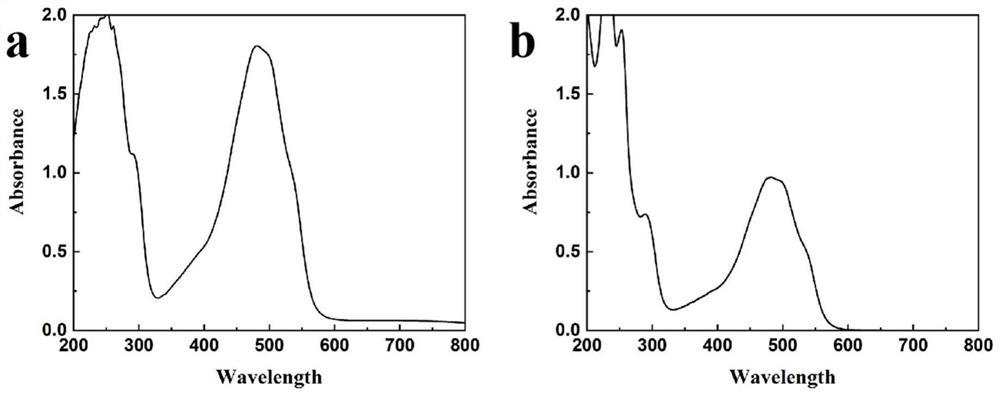

[0095] (1) Take by weighing 0.5g chitosan, 0.25g sulfonated chitosan and 0.25g sodium alginate respectively, and prepare a mixed aqueous solution with a mass fraction of 1%;

[0096] (2) Contain 4.5g Span 80 and 0.5g Tween 20 in 100mL petroleum ether for preparing emulsifier solution;

[0097] (3) Add 10mL chitosan / sulfonated chitooligosaccharide / sodium alginate aqueous solution dropwise into the organic solvent containing emulsifier through a syringe pump, and stir evenly to form an emulsion at a speed of 520rpm;

[0098] (4) After stirring at a constant speed for 3 hours, add 5 mL of 0.08 g / mL CaCl 2 Aqueous solution, 100 μL 50% (v / v) glutaraldehyde, stirred for 3 hours, added 100 μL 10% (v / v) terephthalaldehyde, continued to stir for 6 hours;

[0099] (5) Thermally induce phase separation of the above emulsion at -80°C-20°C, freeze treatment for 4 hours, then remove the upper layer of the emulsion, leaving the lower layer of microspheres, and then wash with deionized water...

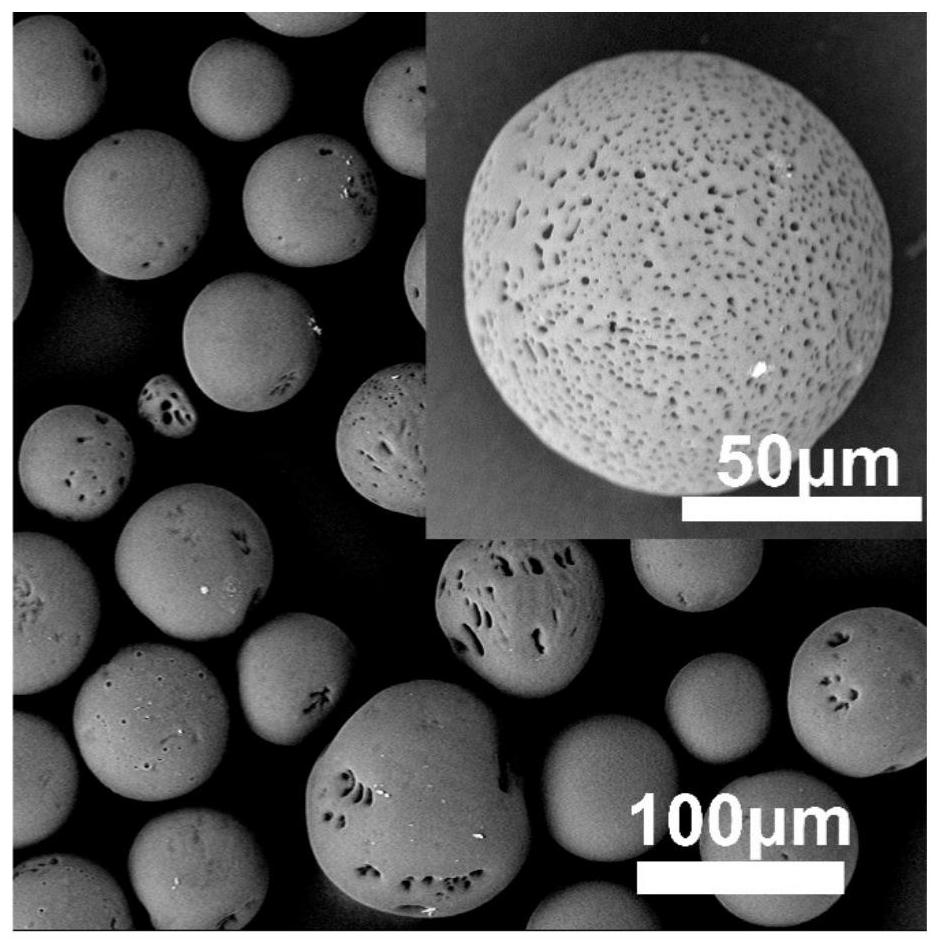

Embodiment 3

[0103] (1) Take by weighing 0.142g chitosan, 0.429g sulfonated chitosan and 0.429g sodium alginate respectively, and prepare a mixed aqueous solution whose mass fraction is 1%;

[0104] (2) Prepare an emulsifier solution containing 4.8g Span 80 and 0.2g Tween 20 in 100mL petroleum ether;

[0105] (3) Add 10mL chitosan / sulfonated chitooligosaccharide / sodium alginate aqueous solution dropwise into the organic solvent containing emulsifier through a syringe pump, and stir evenly to form an emulsion at a speed of 520rpm;

[0106] (4) After stirring at a constant speed for 3 hours, add 7.5mL of 0.08g / mL CaCl 2 Aqueous solution, 50 μL of 50% (v / v) glutaraldehyde, stirred for 3 hours, added 100 μL of 10% (v / v) terephthalaldehyde, and continued to stir for 12 hours;

[0107] (5) Thermally induce phase separation of the above emulsion at -80°C-20°C, freeze treatment for 4 hours, then remove the upper layer of the emulsion, leaving the lower layer of microspheres, and then wash with de...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Adsorption capacity | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com