Iron-doped carbon nitride diatomite composite material and preparation method and application thereof

A carbon nitride diatomite and composite material technology, applied in chemical instruments and methods, special compound water treatment, catalyst carriers, etc., can solve the problems of poor visible light absorption, low photocatalytic efficiency, etc., and achieve adsorption performance and photocatalytic performance. Lifting, strong adsorption effect, large specific surface area effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

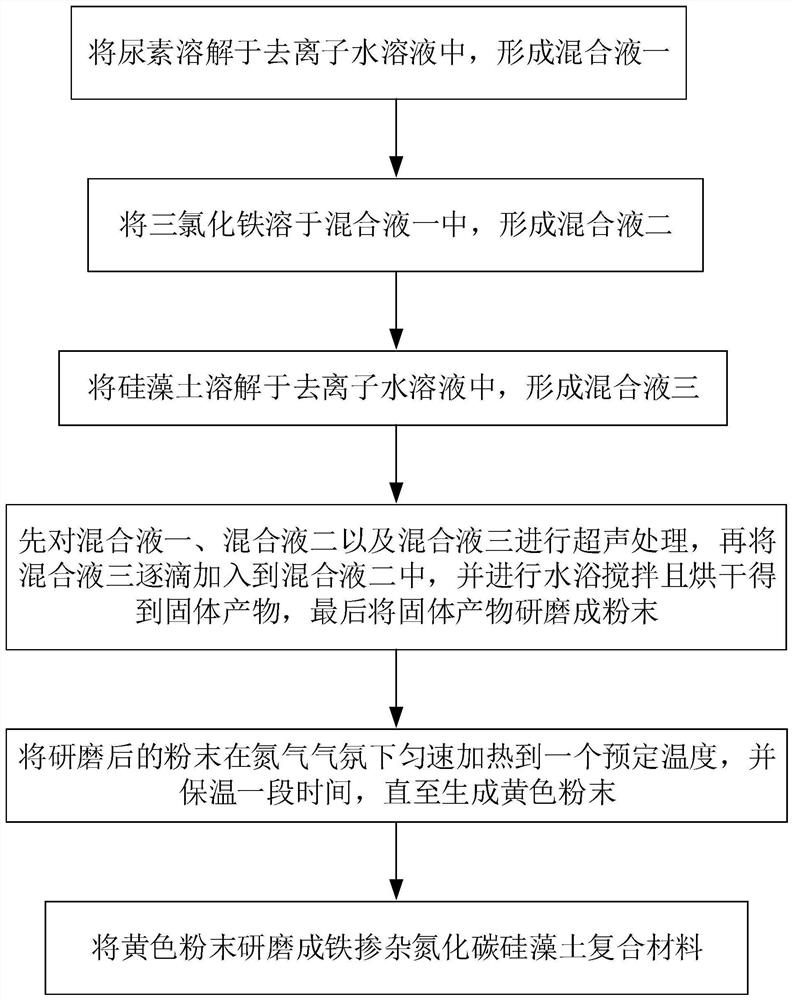

[0040] see figure 1 , this embodiment provides a method for preparing an iron-doped carbon nitride diatomite composite material, which is used to prepare an iron-doped carbon nitride diatomite composite material, namely Fe-g-C 3 N 4 / DE material. Wherein, the preparation method includes the following steps, namely steps (1)-(6).

[0041] (1) Dissolving urea in a deionized aqueous solution to form a mixed solution one. In this example, urea was dissolved in 30 ml of deionized water to form a urea solution, ie mixed solution one.

[0042] (2) Dissolve ferric chloride in mixed solution 1 to form mixed solution 2. In this embodiment, the amount of ferric chloride is 80 mg, that is, 80 mg of ferric chloride is placed in the urea solution obtained in the previous step.

[0043] (3) Diatomaceous earth was dissolved in deionized aqueous solution to form a mixed liquid three. In this embodiment, the mass ratio of urea and diatomite is 1:10, and diatomite is dissolved in 20 ml of ...

Embodiment 2

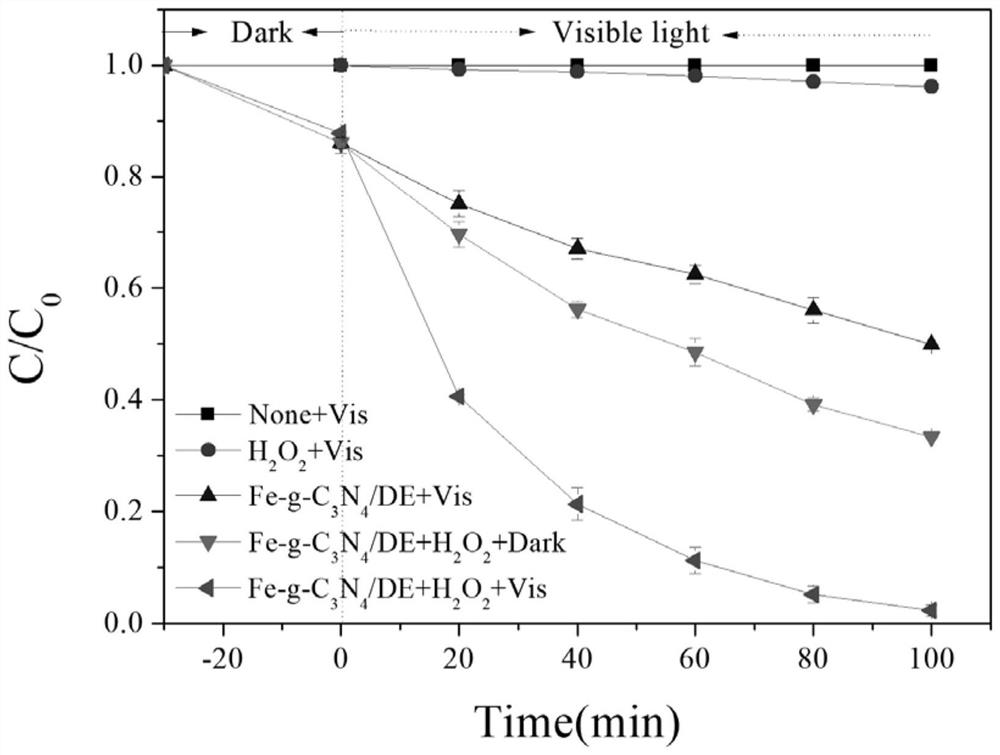

[0050] This example provides a method for adsorption and degradation of tetracycline in water. The method uses the iron-doped carbon nitride diatomite composite material prepared by the method for preparing the iron-doped carbon nitride diatomite composite material in Example 1. Adsorption and degradation of tetracycline in water. Fe-g-C 3 N 4 The / DE multifunctional nanocomposite can adsorb and degrade tetracycline in water, and use it as a Fenton-like photocatalyst to adsorb and degrade refractory pollutants, realizing the multifunctional synergy of adsorption / Fenton-like oxidation, and has excellent recyclability , compared with pristine diatomaceous earth and graphitic carbon nitride, the adsorption performance and photocatalytic performance are significantly improved.

Embodiment 3

[0052] This example provides a method for adsorption and degradation of tetracycline in water. The method is used to determine various adsorption conditions of tetracycline in water, so that the optimal adsorption conditions can be determined and efficient adsorption and degradation of tetracycline in water can be realized. Wherein, the adsorption degradation method includes the following steps, namely steps (a), (b), (c) and (d).

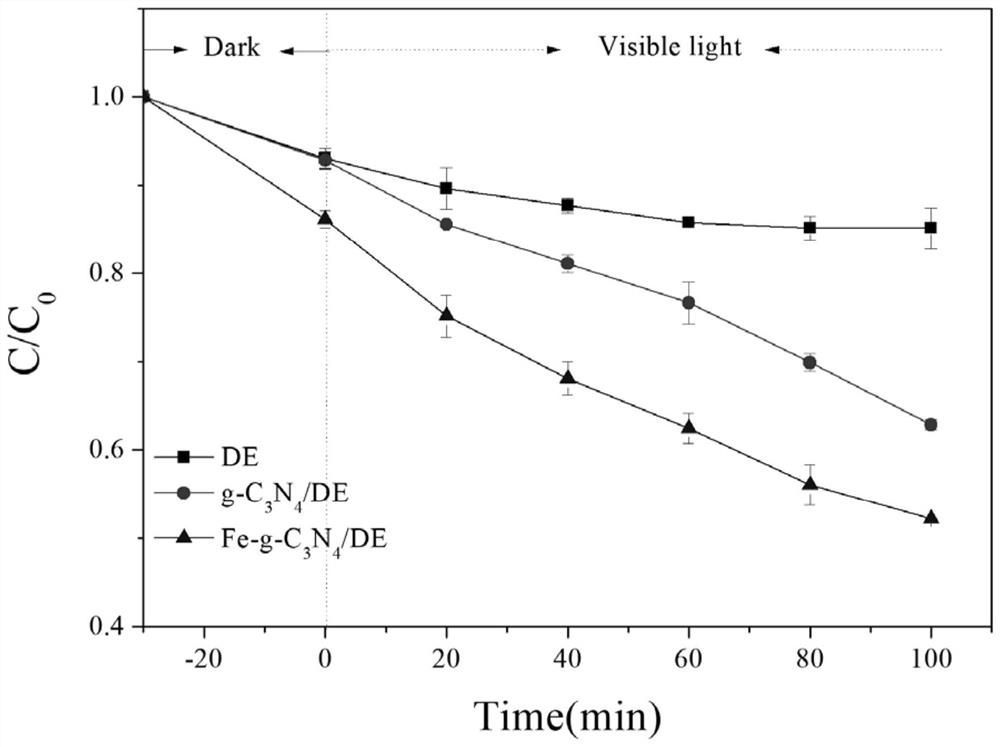

[0053] (a) First, the same amount of diatomite, doped carbon nitride diatomite composite material, and iron-doped carbon nitride diatomite composite material prepared by the iron-doped carbon nitride diatomite composite material in Example 1 were prepared. The diatomite composite material was added to tetracycline solutions with different concentrations and shaken, and then the adsorption rate of diatomite, carbon nitride-doped diatomite composite material and iron-doped carbon nitride diatomite composite material to tetracycline was measured . In...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com