Cultivating fertilizer for promoting plant root growth and processing method thereof

A plant root system and processing method technology, applied in the direction of organic fertilizers, fertilizer mixtures, ammonium orthophosphate fertilizers, etc., can solve the problems of reducing the service life of chemical fertilizers, use efficiency, inconvenience in transportation and application, and calcium affecting crop yields, etc., to increase Phosphorus utilization, loss of inhibition, effect of increasing utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

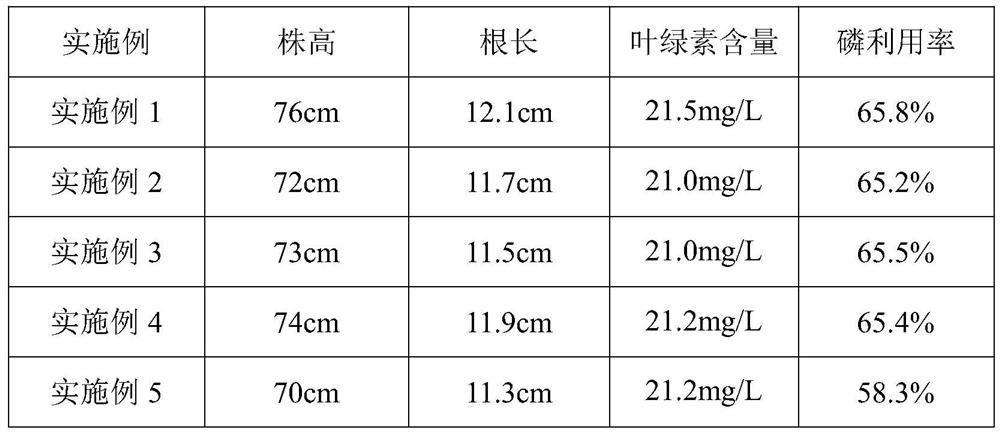

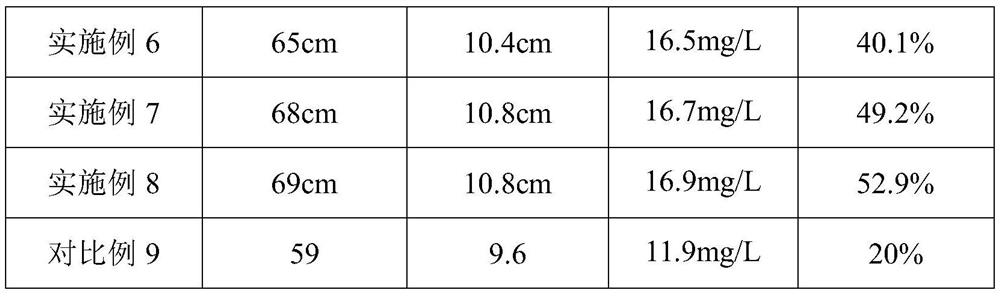

Examples

Embodiment 1

[0028] A processing method of a cultivation fertilizer for promoting plant root growth, comprising the following steps:

[0029]S1: Preparation of porous composite: (1) Preparation of porous carboxymethyl starch: sieve the carboxymethyl starch and weigh it according to the amount, and ultrasonically disperse it in the citric acid-disodium hydrogen phosphate buffer solution to obtain a homogeneous solution; Transfer to the reaction kettle, set the stirring speed to 300rmp, add amylase and glucoamylase, set the reaction temperature to 35°C for 14 hours; add 4wt% sodium hydroxide to terminate the reaction; wash and filter, dry at 50°C to obtain porous carboxyl Methyl starch; (2) Preparation of iron-based porous carboxymethyl starch: ultrasonically disperse the prepared porous carboxymethyl starch in deionized water; transfer it to the reactor, set the stirring speed to 1100rmp, and slowly add ferric chloride , stirred for 1 hour; centrifuged, dried at 50°C to obtain iron-based po...

Embodiment 2

[0033] A processing method of a cultivation fertilizer for promoting plant root growth, comprising the following steps:

[0034] S1: Preparation of porous composite: (1) Preparation of porous carboxymethyl starch: sieve the carboxymethyl starch and weigh it according to the amount, and ultrasonically disperse it in the citric acid-disodium hydrogen phosphate buffer solution to obtain a homogeneous solution; Transfer to the reaction kettle, set the stirring speed to 300rmp, add amylase and glycoamylase, set the reaction temperature to 35°C for 12 hours; add 3wt% sodium hydroxide to terminate the reaction; wash and filter, dry at 50°C to obtain porous carboxyl Methyl starch; (2) Preparation of iron-based porous carboxymethyl starch: ultrasonically disperse the prepared porous carboxymethyl starch in deionized water; transfer it to the reactor, set the stirring speed to 900rmp, and slowly add ferric chloride , stirred for 1 hour; centrifuged, and dried at 50°C to obtain iron-base...

Embodiment 3

[0038] A processing method of a cultivation fertilizer for promoting plant root growth, comprising the following steps:

[0039] S1: Preparation of porous composite: (1) Preparation of porous carboxymethyl starch: sieve the carboxymethyl starch and weigh it according to the amount, and ultrasonically disperse it in the citric acid-disodium hydrogen phosphate buffer solution to obtain a homogeneous solution; Transfer to the reaction kettle, set the stirring speed to 500rmp, add amylase and glucoamylase, set the reaction temperature to 38°C for 16 hours; add 4wt% sodium hydroxide to terminate the reaction; wash and filter, dry at 50°C to obtain porous carboxyl Methyl starch; (2) Preparation of iron-based porous carboxymethyl starch: ultrasonically disperse the prepared porous carboxymethyl starch in deionized water; transfer it to the reactor, set the stirring speed to 1100rmp, and slowly add ferric chloride , stirred for 2 hours; centrifuged and dried at 50°C to obtain iron-bas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com