Anti-alcohol probiotic fruit and vegetable freeze-dried powder and preparation method thereof

A technology of freeze-dried powder and probiotics, applied in biochemical equipment and methods, methods based on microorganisms, bacteria used in food preparation, etc., can solve problems such as unsatisfactory hangover effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] A kind of preparation method of hangover probiotic fruit and vegetable freeze-dried powder, its specific steps are as follows:

[0037] 1) Preparation of seed liquid: Streak culture of Lactobacillus reuteri, Lactobacillus plantarum, Lactobacillus bulgaricus, Lactobacillus casei, Lactobacillus helveticus, Lactobacillus rhamnosus and Streptococcus thermophilus on solid medium respectively, Pick a newly activated single colony to connect to the liquid medium, and culture it with shaking until the logarithmic growth phase as the seed liquid;

[0038] 2) Net selection of raw materials, including 20-45 parts by weight of carrots, 10-20 parts by weight of tomatoes, 10-15 parts by weight of cabbage and 5-10 parts by weight of soy milk; add 20-60 parts by weight of water, beat, adjust When the pH reaches 5.0-5.5, put it into a high-temperature instant sterilizer, undergo high-temperature instant sterilization at 142 °C for 3-5 seconds, and then cool to 37 °C;

[0039] 3) Using ...

Embodiment 1

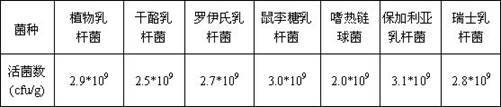

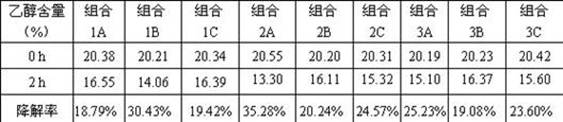

[0046] Example 1 Bacterial strain cultivation and ethanol-resistant performance test of the bacterial strain

[0047] 1) culture medium

[0048] MRS liquid medium: peptone 10g / L, beef extract 10g / L, yeast extract 5g / L, disodium hydrogen citrate 2g / L, glucose 10g / L, Tween 80 1mL / L, sodium acetate 5g / L, phosphoric acid Sodium hydrogen disodium 2g / L, magnesium sulfate 0.58 g / L, manganese sulfate 0.25 g / L, pH 6.2-6.6, sterilized at 121°C for 20 min.

[0049] MRS solid medium: add 20 g / L agar powder on the basis of MRS liquid medium configuration, and sterilize at 121°C for 20 minutes.

[0050] 2) Inoculate Lactobacillus reuteri, Lactobacillus plantarum, Lactobacillus bulgaricus, Lactobacillus casei, Lactobacillus helveticus, Lactobacillus rhamnosus, and Streptococcus thermophilus into MRS solid medium for streak culture, and then pick new ones respectively. The activated single colony was inoculated in 100 mL of MRS liquid medium, and cultured statically in a 37°C incubator for ...

Embodiment 2

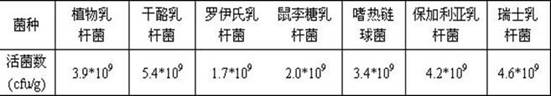

[0054] Example 2 Preparation of probiotic fruit and vegetable fermented freeze-dried powder 1

[0055] 1) Culture medium configuration

[0056] Weigh 20 parts by weight of carrots, 20 parts by weight of tomatoes, 15 parts by weight of cabbage, 10 parts by weight of soybean milk, and 20 parts by weight of water, make a slurry, adjust the pH to 5.5 for later use; put the above raw materials into a high-temperature instant sterilizer sterilized at 142°C for 3 s, and then cooled to 37°C.

[0057] 2) Inoculation and fermentation

[0058] Fill the prepared medium separately, inoculate Lactobacillus reuteri, Lactobacillus plantarum, Lactobacillus bulgaricus, Lactobacillus casei, Lactobacillus helveticus, Lactobacillus rhamnosus, and Streptococcus thermophilus with 3% seed liquid into the fermentation The raw material solution was fermented at 37°C at a speed of 3000 r / min for 20 h to obtain a fermentation broth.

[0059] 3) Low-temperature vacuum freeze-drying

[0060] Centrifuge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com