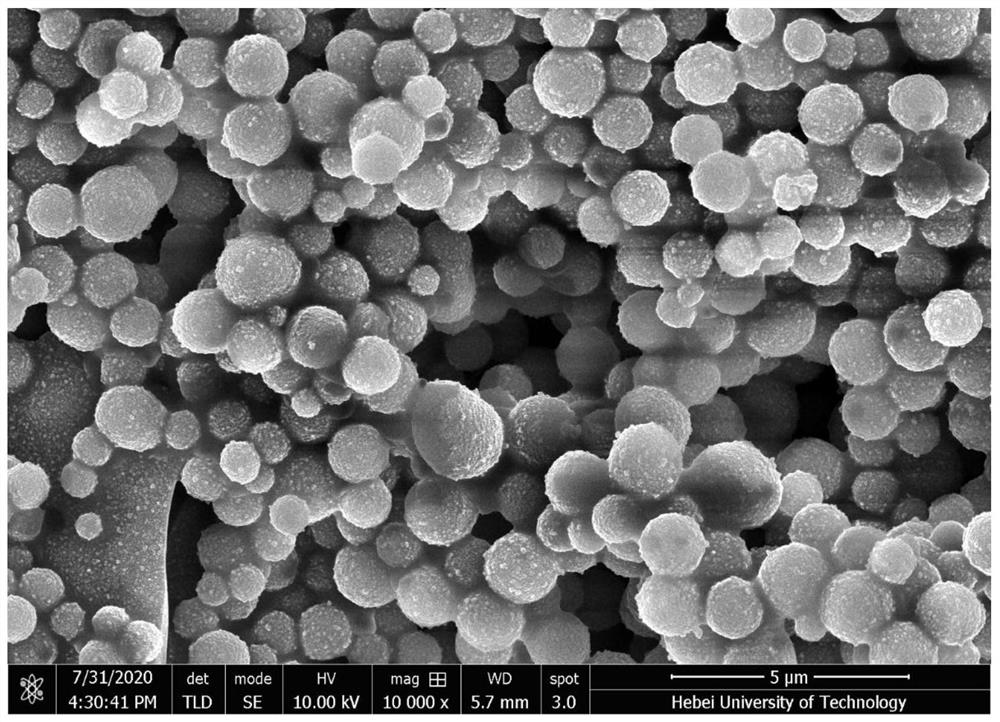

Preparation method of enzyme-loaded xerogel monolithic column catalytic filler

A catalytic filler and xerogel technology, applied in biochemical equipment and methods, fixed on/in organic carriers, enzymes, etc., can solve the problems of reaction system pollution, reaction system complexity, post-processing difficulty, etc. Achieve the effect of good selectivity, high activity and fast reaction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

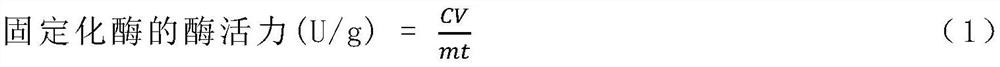

Method used

Image

Examples

Embodiment 1

[0037] (1) Weigh 0.58g of methyl orthosilicate and 2.08g of methyltrimethoxysilane, mix and dissolve them in 3.39g of methanol.

[0038] (2) Put the solution prepared in step (1) into an ice-water bath for later use.

[0039] (3) Weigh 0.14g polyethylene glycol, 0.49g NaF, 1.26g enzyme solution (Candida antarctica lipase B solution; concentration: 6wt%), 2.06g deionized water, mix and stir evenly.

[0040] (4) Slowly pour the enzyme-containing mixed solution obtained in step (3) into the mixed solution in step (1), and stir in an ice-water bath for 3 minutes to obtain an enzyme-loaded wet gel.

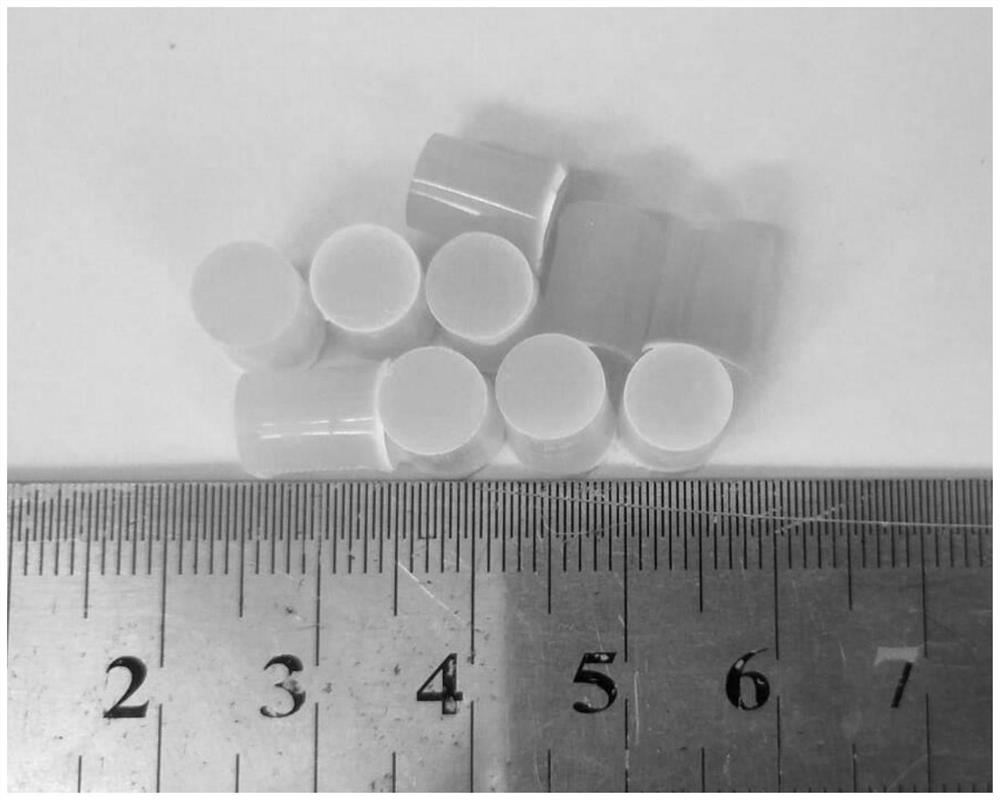

[0041] (5) Cut a plastic round tube with an inner diameter of 1 cm and a thickness of 2 mm into 1.7 cm long pieces, a total of 10 pieces, glue one side of the cut piece to a 5×6 cm plastic plate, and place it at 60°C After drying in an oven for 12 hours at a degree Celsius, a cylindrical mold was obtained.

[0042] (6) Transfer the enzyme-loaded wet gel obtained in step (4) to the cy...

Embodiment 2

[0046] The difference between this embodiment and embodiment 1 is that the opening ratio of the perforated holes on the plastic wrap is replaced by 8%, the temperature of the mold putting into the oven is replaced by 35°C, and other conditions are completely the same as in embodiment 1.

Embodiment 3

[0048] The difference between this embodiment and embodiment 1 is that the opening ratio of the perforated holes on the plastic wrap is replaced by 6%, the temperature of the mold being put into the oven is replaced by 25° C., and other conditions are completely the same as in embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com