Preparation method and application of nanostar chain-shaped nanostructure arrays

A technology of nanostructure and micro-nanostructure, applied in the direction of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problem of limited improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

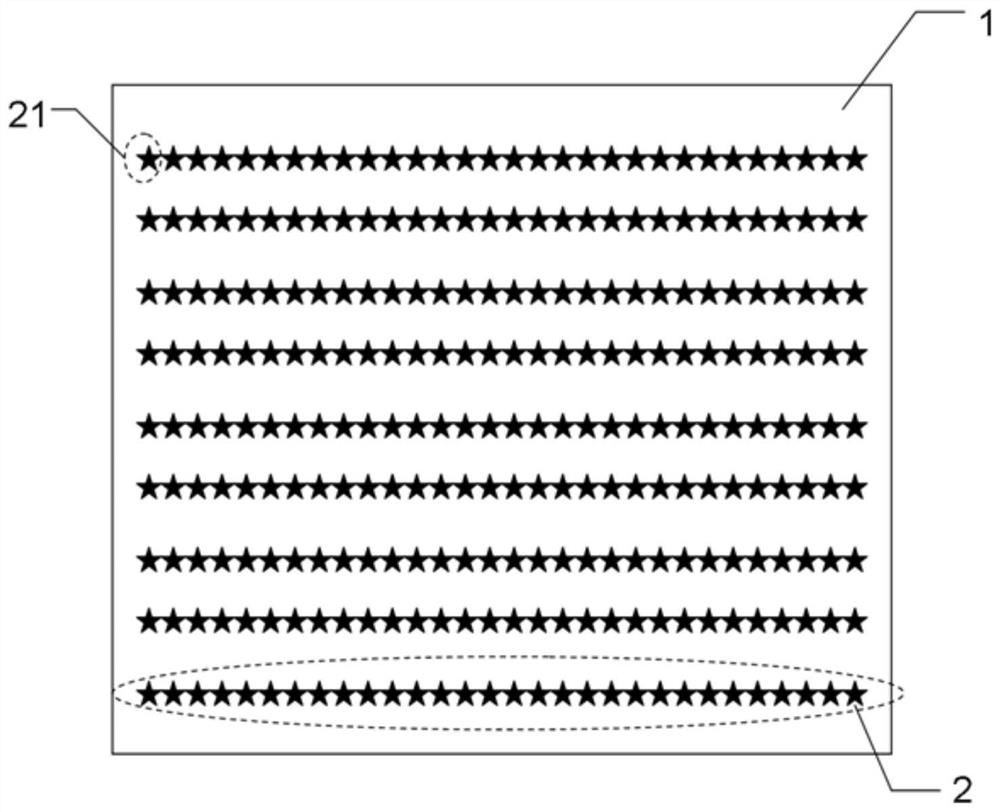

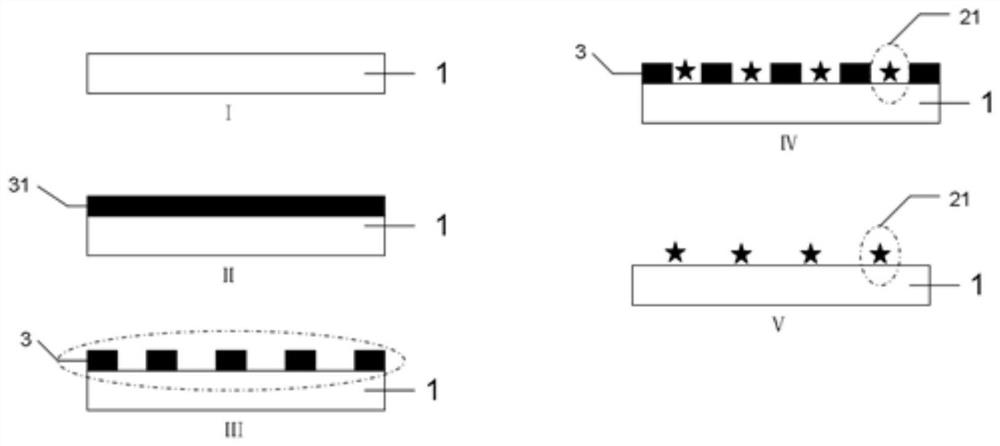

[0033] A photoresist layer with a two-dimensional strip-shaped hollow unit structure is prepared by wet etching, and the process is as follows figure 2 Shown:

[0034] First substrate 1, such as glass or conductive glass or silicon wafer, is thoroughly cleaned by detergents such as acetone, isopropanol, etc., to remove impurity ions (such as Figure 2-I );

[0035] Then spin-coat one layer of positive photoresist film 31 (such as Figure 2-Ⅱ ), the thickness of the photoresist layer is more than 200nm, after drying, the mask plate with the two-dimensional strip micro-nano structure array pattern is used for exposure, after the exposure, post-baking and development are carried out, so that the surface of the substrate 1 is obtained. The photoresist layer 3 of the micro-nano structure array pattern (such as figure 2 -III), the micro-nano structure array pattern is composed of a plurality of two-dimensional strip-shaped hollow unit structures, and the process of exposure and...

Embodiment 2

[0039] Preparation of gold nanostar particle sol:

[0040] ① Mix 0.250mL chloroauric acid solution (0.01M) and 7.5mL CTAB solution (0.1M) evenly, add 0.6mL sodium borohydride solution (0.01M), and shake gently to form a dark brown gold seed solution, which Store in the dark for 2 hours before use;

[0041] ② Take another 10mL vial, add 4.75mL of the above CTAB solution and 0.2mL of the above chloroauric acid solution into the vial, shake gently to mix the two evenly, then add 0.03mL of silver nitrate solution (0.01M) and 0.032mL of Ascorbic acid solution (0.1M), after mixing, a colorless growth solution is obtained, which is ready for use;

[0042] ③Then add 20μl of gold seed solution to 20mL of growth solution, shake and mix evenly, and let it stand at room temperature for more than 3 hours to obtain a dark blue gold nanostar particle sol, and then after aging for 12 hours, perform two centrifuges to remove excess reaction The pure gold nanostar particle sol was obtained. ...

Embodiment 3

[0045] Depositing Gold Nanostar Particles:

[0046] The gold nanostar particle sol (such as figure 2 -Ⅳ), and air-dried naturally, the distribution density of gold nanostars was monitored by scanning electron microscopy to ensure the formation of chain-like nanostructures of nanostars in the hollow unit structure. According to the actual situation, the sol of gold nanostar particles can be drip-coated multiple times to ensure that the gold nanostar particles are in a continuous chain distribution state in the strip-shaped hollow unit structure of the photoresist layer (such as figure 1 shown in Mark 2).

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com