Engineering saccharomyces cerevisiae and method for preparing artificial bear bile powder

A technology of Saccharomyces cerevisiae and bear bile powder, which is applied in the fields of biotechnology and medicine, can solve problems such as large disputes, endanger the health and protection of bears, and achieve the effects of fast transformation, meeting the needs of the pharmaceutical market, and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] Embodiment 1 Engineering Saccharomyces cerevisiae construction and thalline collection

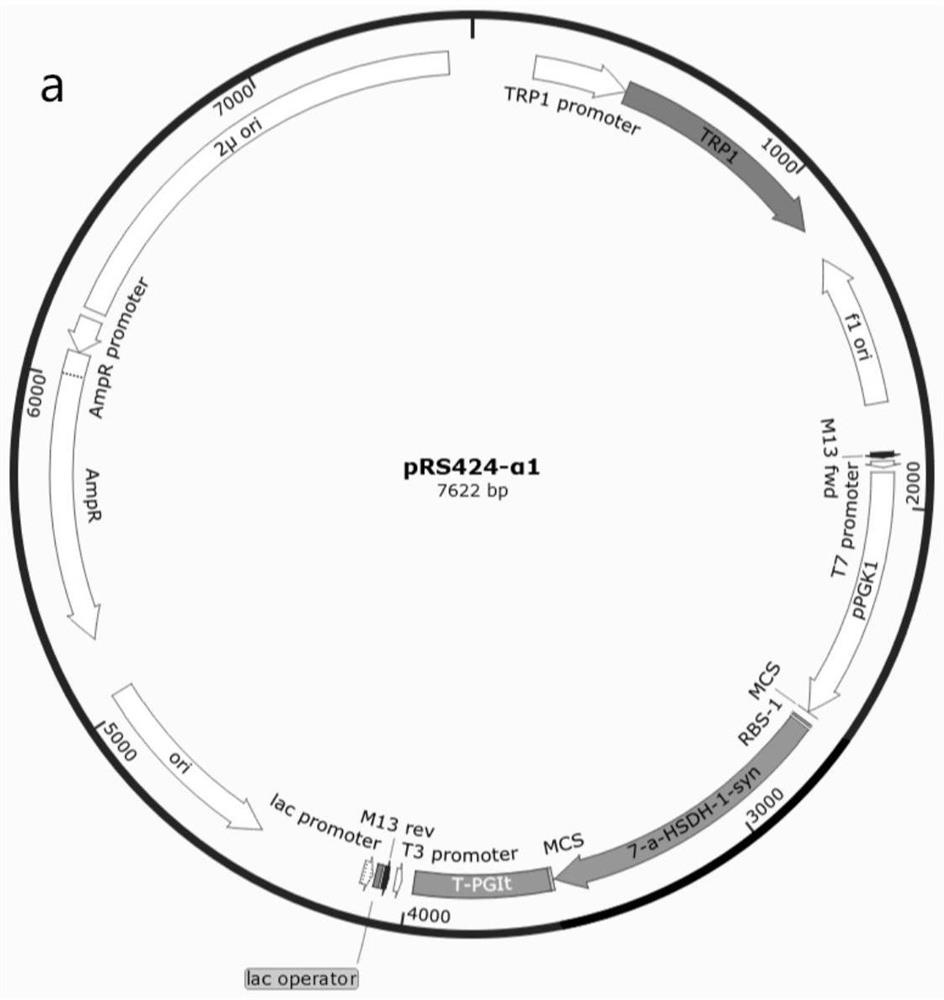

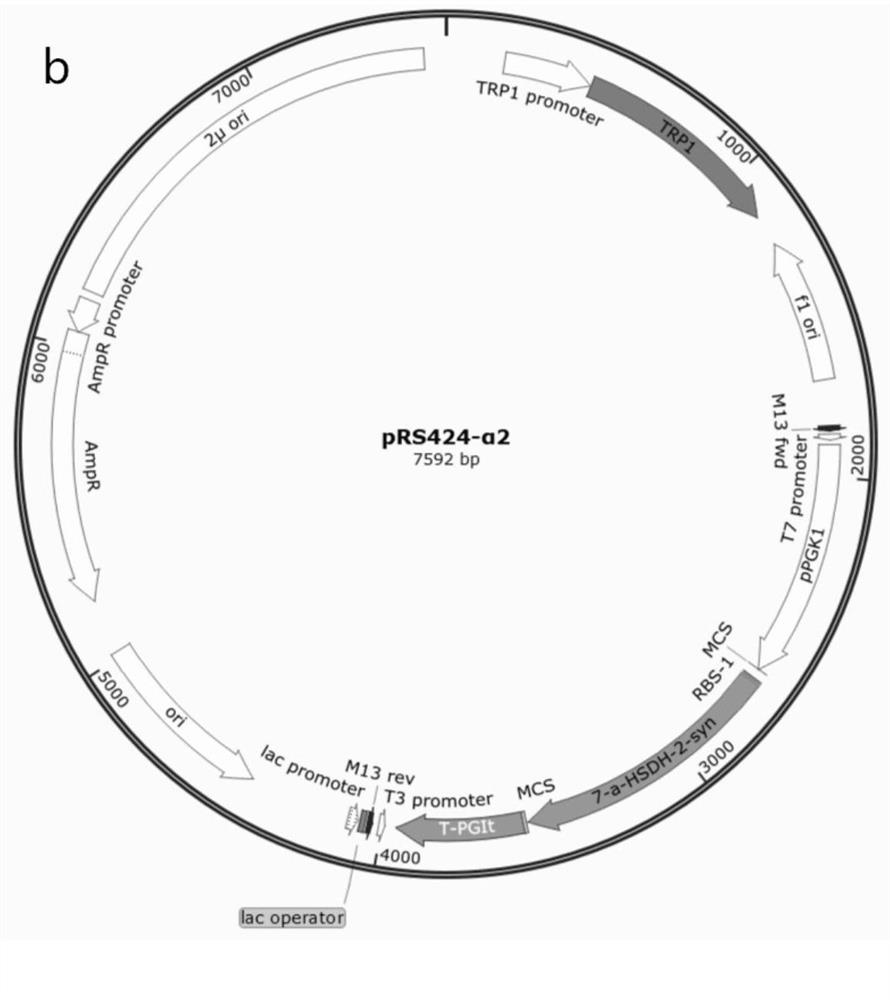

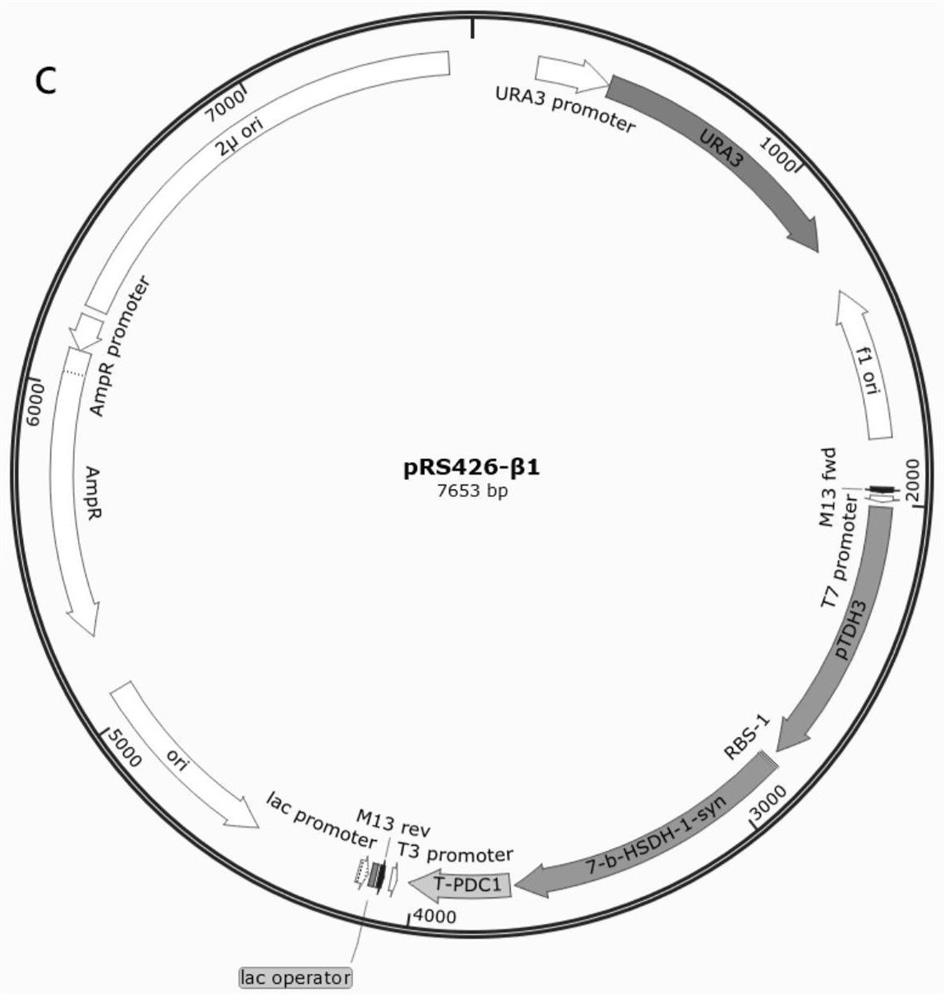

[0061] (1) Vector construction: two 7α-HSDH and two 7β-HSDH genes (the nucleotide sequences of which are respectively shown in SEQ ID No.1-No.4) were respectively connected to pRS424 by double enzyme digestion and T4 ligase ligation and pRS426 plasmid vectors, respectively named pRS424-α 1 , pRS424-α 2 , pRS426-β 1 , pRS426-β 2 . Its structure is as follows Figure 1-Figure 4 shown.

[0062] (2) Construction of engineering Saccharomyces cerevisiae: pRS424-α 1 , pRS424-α 2 , pRS426-β 1 , pRS426-β 2 Transformed into Saccharomyces cerevisiae CEN.PK2-1C and W303a competent cells respectively to obtain engineering Saccharomyces cerevisiae CEN.PK2-1C-pRS424-α 1 -pRS426-β 1 , CEN.PK2-1C-pRS424-α 1 -pRS426-β 2 , CEN.PK2-1C-pRS424-α 2 -pRS426-β 1 , CEN.PK2-1C-pRS424-α 2 -pRS426-β 2 , W303a-pRS424-α 1 -pRS426-β 1 , W303a-pRS424-α 1 -pRS426-β 2 , W303a-pRS424-α 2 -pRS426-...

Embodiment 3

[0071] Example 3 Preparation of Crude Enzyme Liquid and Crude Enzyme Powder by Pickling Glass Beads Method

[0072] (1) 10 milliliters of engineered Saccharomyces cerevisiae culture fluid according to step (3) of Example 2, centrifuged at 2200 rpm for 5 minutes at 4° C., and discarded the supernatant.

[0073] (2) Resuspend the bacteria in 500 μL of sterile water, transfer to a centrifuge tube, centrifuge at 4°C and 13,000 rpm for 60 seconds at high speed, discard the supernatant, and freeze the cells at -80°C for later use.

[0074] (3) Resuspend the cells with 500 μL of cell disruption buffer (50 mM sodium phosphate buffer, pH 6.5, 5% glycerol), centrifuge at 2200 rpm at 4° C. for 5 minutes, and discard the supernatant.

[0075] (4) Resuspend the cells with 150 μL cell disruption buffer, add the same volume of acid-washed glass beads (424-600 μm), vortex mix-ice bath (vortex mix for 30 seconds, ice bath for 30 seconds, repeat 10 times, total time 10 minutes) to fully lyse t...

Embodiment 4

[0078] Example 4 Homogenizer Crushing Method Prepares Crude Enzyme Liquid and Crude Enzyme Powder

[0079] (1) The 6 liters of engineered Saccharomyces cerevisiae culture solution obtained by the operation in step (4) of Example 2 was centrifuged at 3500 rpm and 4° C. for 10 minutes, and the supernatant was discarded.

[0080] (2) Resuspend the bacterial cells in 200 ml of sterile water, transfer to a centrifuge tube, centrifuge at 12,000 rpm for 60 seconds, discard the supernatant, and freeze the bacterial cells at -80°C for later use.

[0081] (3) Resuspend the cells with 200 ml of cell disruption buffer, centrifuge at 2600 rpm and 4°C for 10 minutes, and discard the supernatant.

[0082] (4) Resuspend the bacteria with 120 ml of cell breaking buffer, and use a homogenizer to break the cells at 600-1000 bar.

[0083] (5) Centrifuge at 12000rpm for 5-10 minutes, transfer the supernatant to a new centrifuge tube, and obtain crude enzyme solution, or dry it in a freeze dryer t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com