Chemical vapor deposition method and device for submicron diamond film

A technology of chemical vapor deposition and diamond thin film, which is applied in chemical instruments and methods, from chemically reactive gases, single crystal growth, etc., can solve the problems of insufficient adjustment of seed crystal growth pads, pads cannot be self-heated, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

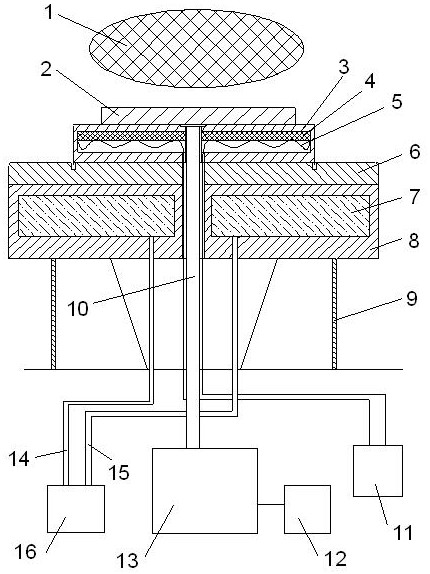

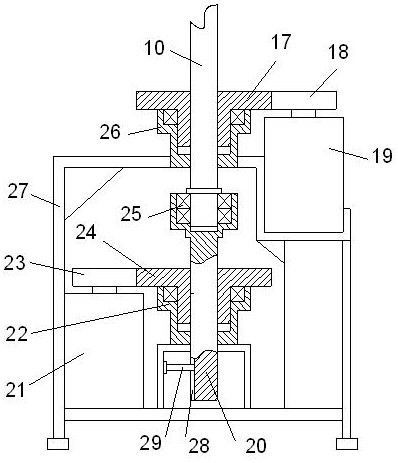

[0030] The device of the present invention is arranged in microwave plasma chemical vapor deposition equipment, and under the action of microwave plasma 1, the submicron diamond film of semiconductor device is prepared, and its structure is as follows figure 1 As shown, it includes a backing plate 3, a tray 6, a quartz window 9 and a backing plate moving mechanism 13. Both the backing plate 3 and the tray 6 are made of molybdenum, and the backing plate 3, the tray 6, the cooling plate 8 and the quartz window 9 are arranged sequentially from top to bottom. Place on cooling plate 8. The cooling plate 8 is made of copper and is set on the quartz window 9 . The centers of the tray 6, the cooling plate 8 and the quartz window 9 all have through holes, and the lifting shaft 10 in the pad moving mechanism passes through these through holes to connect with the pad 3, and the corresponding lines and pipelines are also passed through these through holes. Pass.

[0031] The pad 3 has a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com