Preparation technology and application of environment-friendly comprehensive deodorization biological feed for fattening pigs

A technology of seeds and compound strains, applied in animal feed, animal feed, applications, etc., can solve the problems of reducing the content of odorous substances in pig manure, and achieve the effects of improving the air environment of pig houses, reducing feed costs, and good palatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022]1. Preparation of fermentation raw materials

[0023]The fermentation raw material group has become: 95-72% of corn, 5-12% soybean meal, 9-12% of rice bran, 7-10%, stone powder 1.0-1.5%, calcium phosphate 0-0.5, lysine 0.5- 0.9%, methionine 0-0.1%, threonine 0.1-0.2%, tryptophan 0-0.1%, salt 0.2-0.05%, phytase 0.01-0.03%, Multi mine 0.2-0.3 %. The fermentation raw material preparation process is: Pre-mixing calcium hydrogen phosphate, lysine, methionine, threonine, tryptophan, salt, phytase, multi-dimensional and polyterities, and then premixed with corn, soybean meal, Rice bran, bran and stone powder are placed in a mixer, and the finished feed is formulated.

[0024]2. Steel fermentation process

[0025]2.1 Selection of fermentation strains and medium

[0026]A bacteria - Plant Lactobacillus, MRS medium

[0027]Bacteria - Rat Lactobacillus, MRS medium.

[0028]Cyltriline - Bacillus subtilis, LB medium.

[0029]Fungus - Bacillus lichen, LB medium.

[0030]Fungi - Saccharomycestery, YPD medium.

[0031]...

Embodiment 1

[0056]Example 1 Preparation of Composite Fermentation Feed

[0057]A method of preparing a composite fermentation bio feed comprising the steps of:

[0058]1) Feta pig low protein diet materials preparation

[0059]We will weigh the raw materials according to the following ratios: corn 65-72%, soybean meal 5-12%, rice bran 9-12%, bran 7-10%, stone powder 1.0-1.5%, calcium hydrogen phosphate 0-0.2%, 0.5-0.9%, methionine 0-0.1%, threonine 0.1-0.2%, tryptophan 0-0.1%, salt salt 0.2-0.05%, phytase 0.01-0.03%, more Ore 0.2-0.3%. First, small materials (calcium hydrogen phosphate, lysine, methionine, threonine, tryptophan, salt, phytase, multi-dimensional and polyteridium) are prepreg, then premixes and large materials (corn, soybean meal, After the rice bran, bran and stone powder) is fully mixed to obtain fermentation feed raw materials.

[0060]2) Preparation of fermentation seed fluid

[0061]Preparation of Bacillus undergarment, Bacillus Bacillus Bacillus Fermentation Seeds:

[0062]Single colonies se...

Embodiment 2

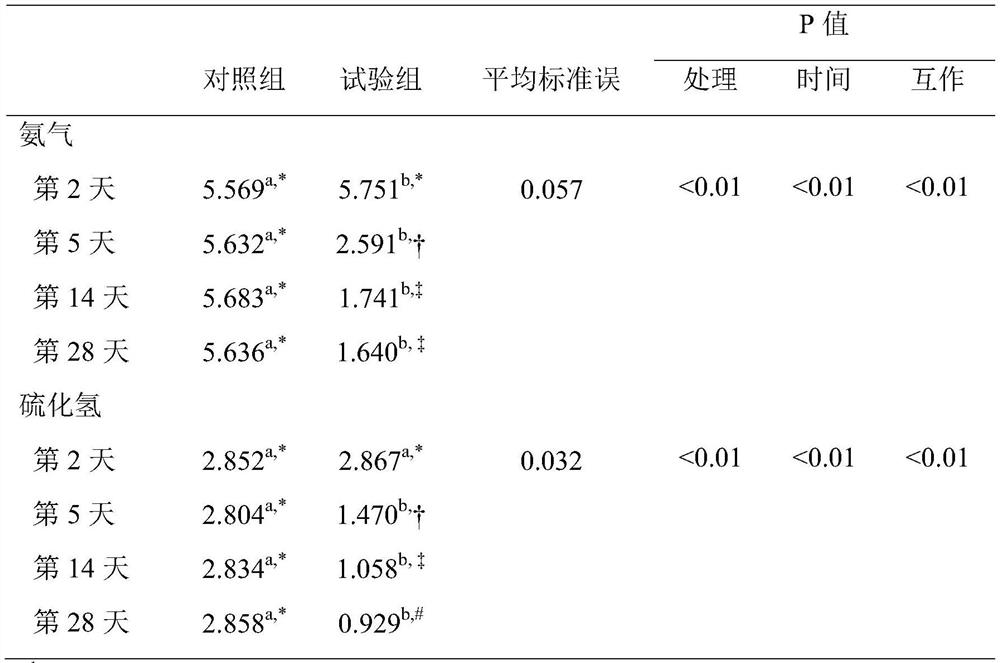

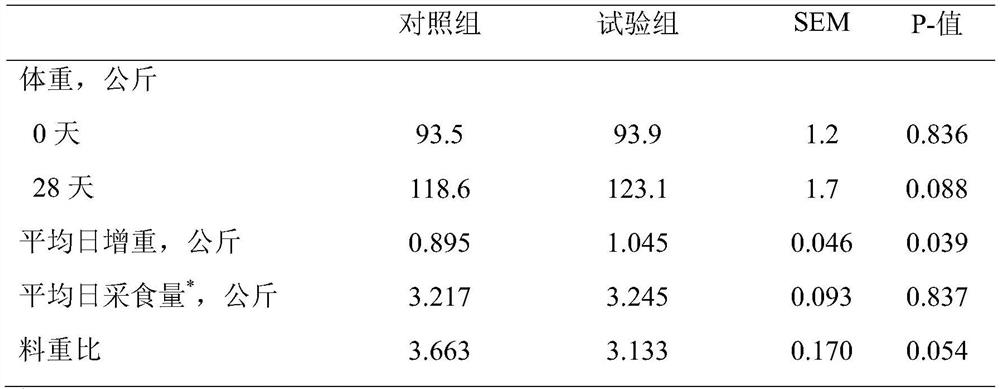

[0070]Example 2 Fermentation Bio Feed Type Pig Breeding

[0071]The test was selected from 200 an average weight of 93.7 kg, and the physical healthy fertilizer pigs were randomly divided into 100 parts of the control group and the test group according to the principle of body weight, and feeding the routine protein feed in control group, feeding the pork. Low protein fermentation feed, each treatment of a pig-bedding 10 column of the same, each column is repeated, each repeating 10 pigs, and performing a 28-day feeding test. Feta pigs are kept in the cement drain ground field, and each repeat is evenly distributed in the indoor control temperature. The area of each column is 10 square meters, and the fan equipped with temperature control is used to maintain ventilation, and the temperature in the house is maintained at 22-25 ° C. All fattening pigs are free to eat and drink water. Observe the test pig feed, health and activity, and do a good job of date and weight. After discovers t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com