A kind of emulsion type bio-based water-based photocurable resin and its preparation method and application

A light-curing resin, bio-based technology, used in non-polymer organic compound adhesives, coatings, adhesives, etc., can solve the problems of difficult preparation of prepolymers, toxicity and irritation, VOC and other problems, and achieve renewable The effect of high carbon content, no interference from oxygen inhibition, and low volume shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0052] The invention provides a method for preparing an emulsion-type bio-based water-based photocurable resin, comprising the following steps:

[0053] (1) Mix the modified polythiol, modified polyolefin, and co-stabilizer to obtain the oil phase; mix the emulsifier and water to obtain the water phase; The following reaction obtains an excessive prepolymer emulsion containing mercapto groups;

[0054] (2) Mix the modified polythiol, modified polyolefin, and co-stabilizer to obtain the oil phase; mix the emulsifier and water to obtain the water phase; mix the oil phase, the water phase, and the photoinitiator in the UV lamp The following reaction obtains an excessive prepolymer emulsion containing double bonds;

[0055] (3) Mix the obtained prepolymer emulsion containing excessive mercapto groups and the prepolymer emulsion containing excessive double bonds to obtain a photocurable resin.

[0056] In the present invention, in step (1) and step (2), the intensity of the ultra...

Embodiment 1

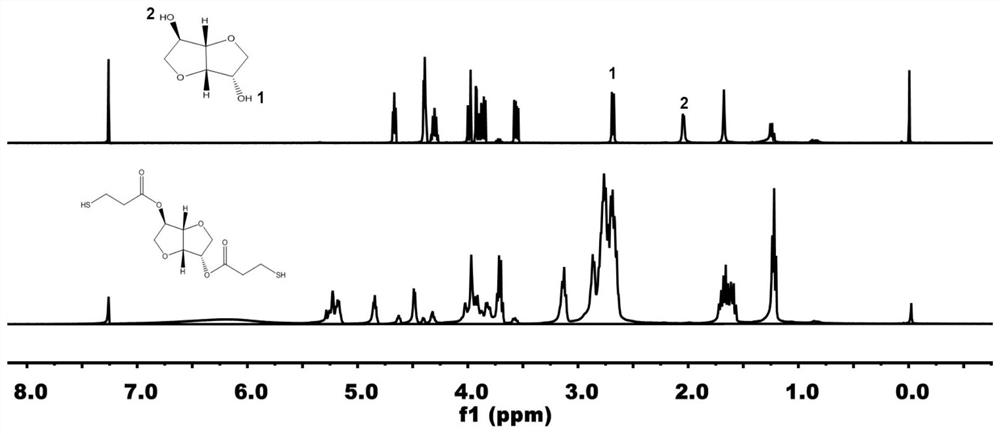

[0062] Synthesis of isosorbide-based dihydric mercaptan monomer (IMASH): get 29.23g of isosorbide and 50.95g of 3-mercaptopropionic acid monomer and add it to a 250ml three-necked flask with water separator and condenser, weigh 4.1 g p-toluenesulfonic acid as a catalyst, 100ml of toluene as a solvent, heat up the oil bath until the temperature in the reactor is 110°C, stop the reaction after 8 hours, add anhydrous sodium carbonate to the product, overnight, filter and wash with saturated saline 3 times, added anhydrous magnesium sulfate to dry, filtered and then rotary evaporated to obtain isosorbide-based dihydric mercaptan.

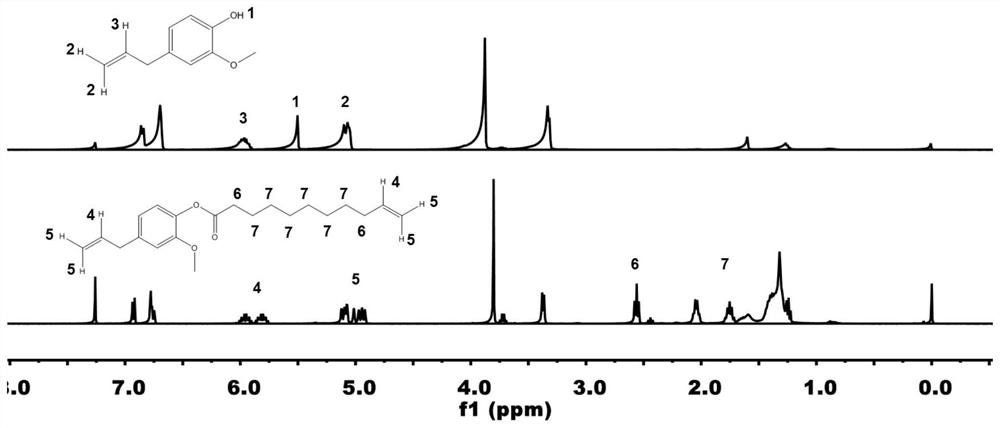

[0063] Synthesis of eugenol-based binary olefin (EUCENE): Take 4.9g of eugenol, 3.4g of triethylamine, and 50ml of dichloromethane into a 250ml three-necked flask, and drop 7.3g of 10-undecene in an ice-water bath Acyl chloride, reacted at low temperature for 20 hours, took the mixture and added it to a pear-shaped separatory funnel, washed three times ...

Embodiment 2

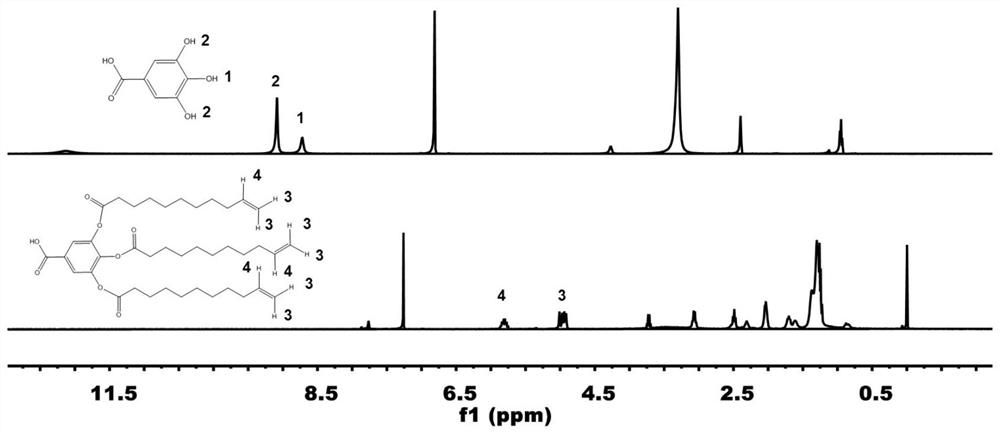

[0068] Synthesis of gallic acid-based ternary olefin (GAENE): Take 17.2g of gallic acid, 32.1g of triethylamine, and 100ml of dichloromethane into a 500ml three-necked flask, and add 66.8g of 10-undecene dropwise under ice-water bath conditions Acyl chloride, reacted at low temperature for 25 hours, took the mixture and put it into a pear-shaped separatory funnel, washed three times with saturated aqueous sodium bicarbonate solution, washed three times with saturated aqueous sodium chloride solution, added anhydrous magnesium sulfate to dry, filtered, and obtained isosorbide di meta-olefins.

[0069] Preparation of mercapto group excess prepolymer emulsion: 0.47g co-stabilizer octadecyl methacrylate was dissolved in monomer 8.22g IMASH and 6.7g GAENE to obtain oil phase; 0.58g emulsifier lauryl sulfate Sodium was dissolved in 25.34 g of water to obtain an aqueous phase. The oil phase was added to the water phase, pre-emulsified by mechanical stirring, and then finely emulsifi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com