Pressure-resistant waterproof rubber sealing ring and preparation method thereof

A rubber sealing ring, pressure-resistant technology, applied in the field of pressure-resistant waterproof rubber sealing ring and its preparation, can solve the problems of fatigue, sealing performance decline, failure and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

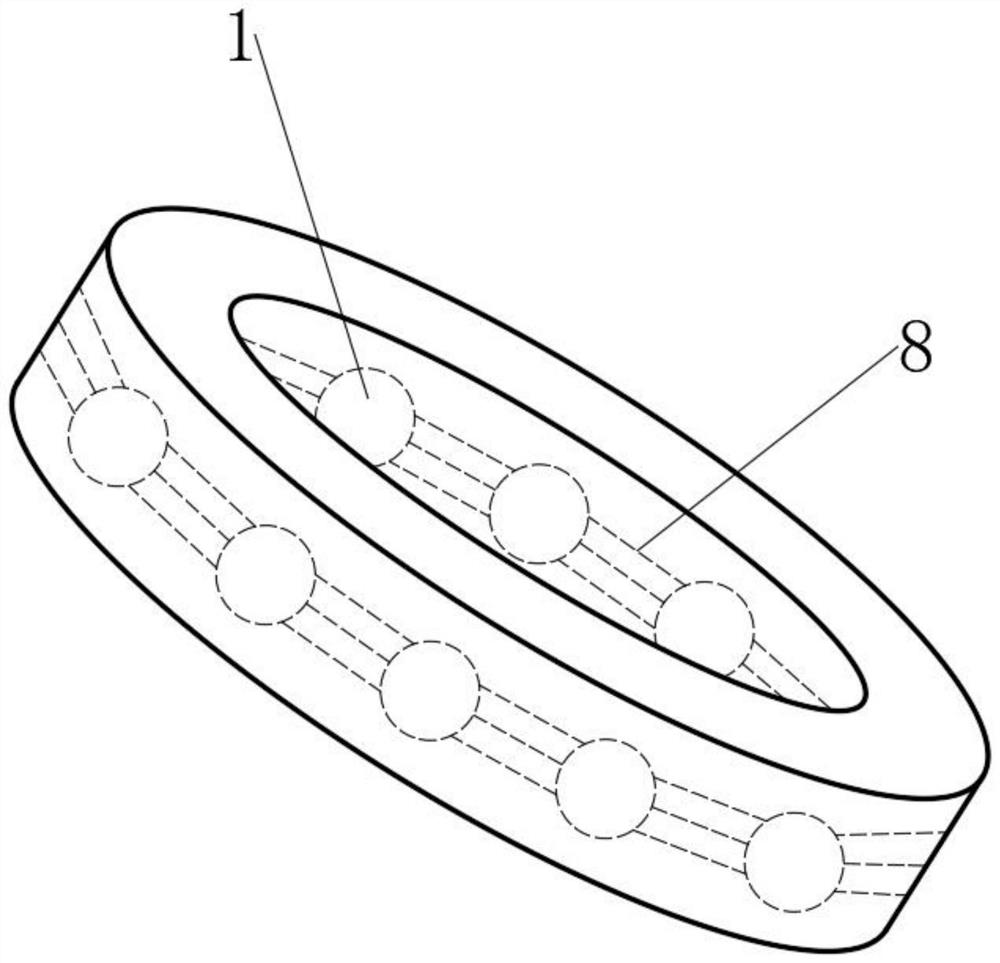

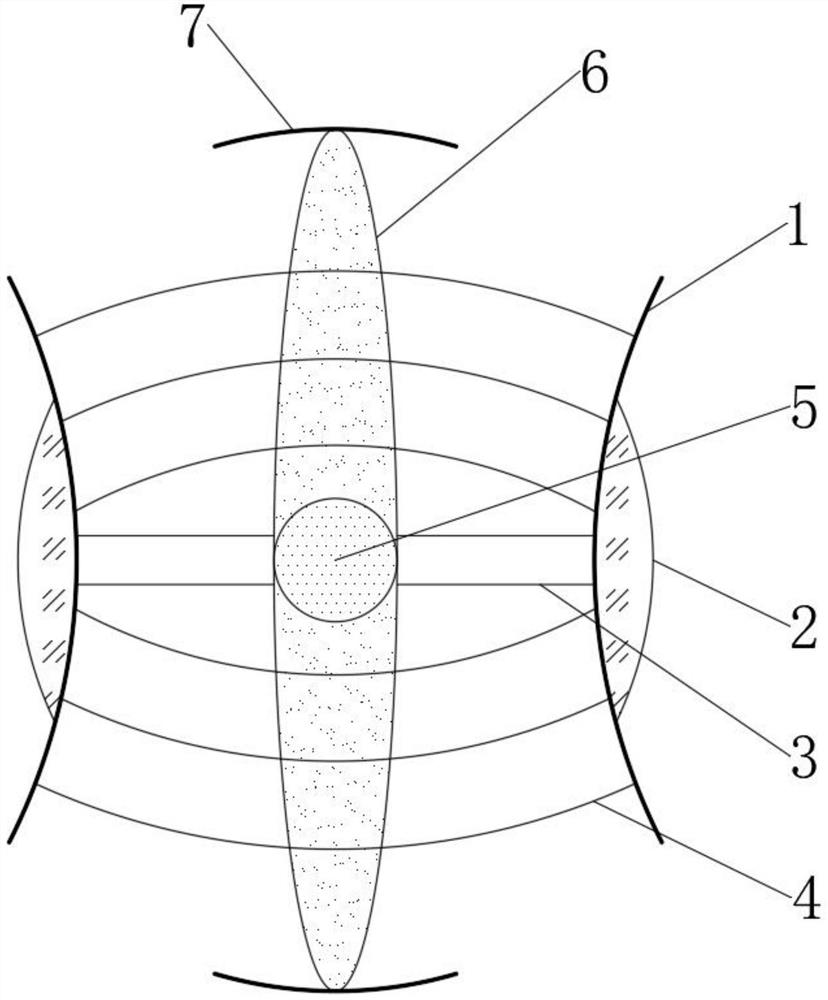

[0041] see figure 1 , a pressure-resistant waterproof rubber sealing ring, comprising the following raw materials in parts by weight: 80 parts of natural rubber, 30 parts of nitrile rubber, 2 parts of stearic acid, 6 parts of reinforcing agent, 2 parts of sulfur powder, accelerator 0.5 parts, 1 part of activated magnesium oxide, 2 parts of filler, 5-8 parts of epoxidized soybean oil, 2.5 parts of carnauba wax, 2 parts of anti-aging agent, 1-part of ethyl methacrylate, 10 parts of shellac paint flakes, hydrophobic 15 parts of permanent silica and 30 parts of pressure-resistant pack.

[0042] The reinforcing agent is one of carbon black, high wear-resistant white carbon black, precipitated calcium carbonate or zinc oxide.

[0043] The accelerator is one of accelerator PZ, accelerator DM, accelerator TMTD and accelerator CZ.

[0044] The filler is one of nano clay, calcium silicate, bentonite, kaolin and mica powder.

[0045] The anti-aging agent is any one or more combination...

Embodiment 2

[0056] A pressure-resistant waterproof rubber sealing ring, comprising the following raw materials in parts by weight: 90 parts of natural rubber, 40 parts of nitrile rubber, 3 parts of stearic acid, 7 parts of reinforcing agent, 2.5 parts of sulfur powder, and 1.5 parts of accelerator 2 parts, active magnesium oxide 2 parts, filler 3 parts, epoxidized soybean oil 6 parts, carnauba wax 3 parts, antioxidant 2.5 parts, ethyl methacrylate 1.5 parts, shellac varnish flakes 11 parts, hydrophobic silica 20 servings and 40 servings in pressure-resistant packs.

[0057] A preparation method of a pressure-resistant waterproof rubber sealing ring, comprising the following steps:

[0058] S1. Weigh natural rubber and nitrile rubber, put them into the open mill, heat to 32°C, set the roller distance to 0.5mm, masticate for 12min, and then go through deglue, tablet, tablet, cool to room temperature and park for 4.5h get plastic rubber;

[0059] S2. Weigh stearic acid, reinforcing agent, ...

Embodiment 3

[0064] A pressure-resistant waterproof rubber sealing ring, comprising the following raw materials in parts by weight: 100 parts of natural rubber, 50 parts of nitrile rubber, 3.5 parts of stearic acid, 8 parts of reinforcing agent, 3 parts of sulfur powder, and 2 parts of accelerator 3 parts of active magnesium oxide, 4 parts of filler, 8 parts of epoxidized soybean oil, 3.5 parts of carnauba wax, 3 parts of anti-aging agent, 2 parts of ethyl methacrylate, 12 parts of shellac paint flakes, hydrophobic silica 25 servings and 45 servings in pressure-resistant packs.

[0065] A preparation method of a pressure-resistant waterproof rubber sealing ring, comprising the following steps:

[0066] S1. Weigh natural rubber and nitrile rubber, put them into an open mill, heat to 35°C, set the roller distance to 0.8mm, masticate for 15min, and then go through rubber removal, tablet pressing, tablet removal, cooling to room temperature and parking for 5h to obtain plastic rubber;

[006...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com