Photochromic composition product suitable for EB curing and preparation method thereof

A technology of photochromism and composition, which is applied in the field of optical film and can solve problems such as photochromic powder damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

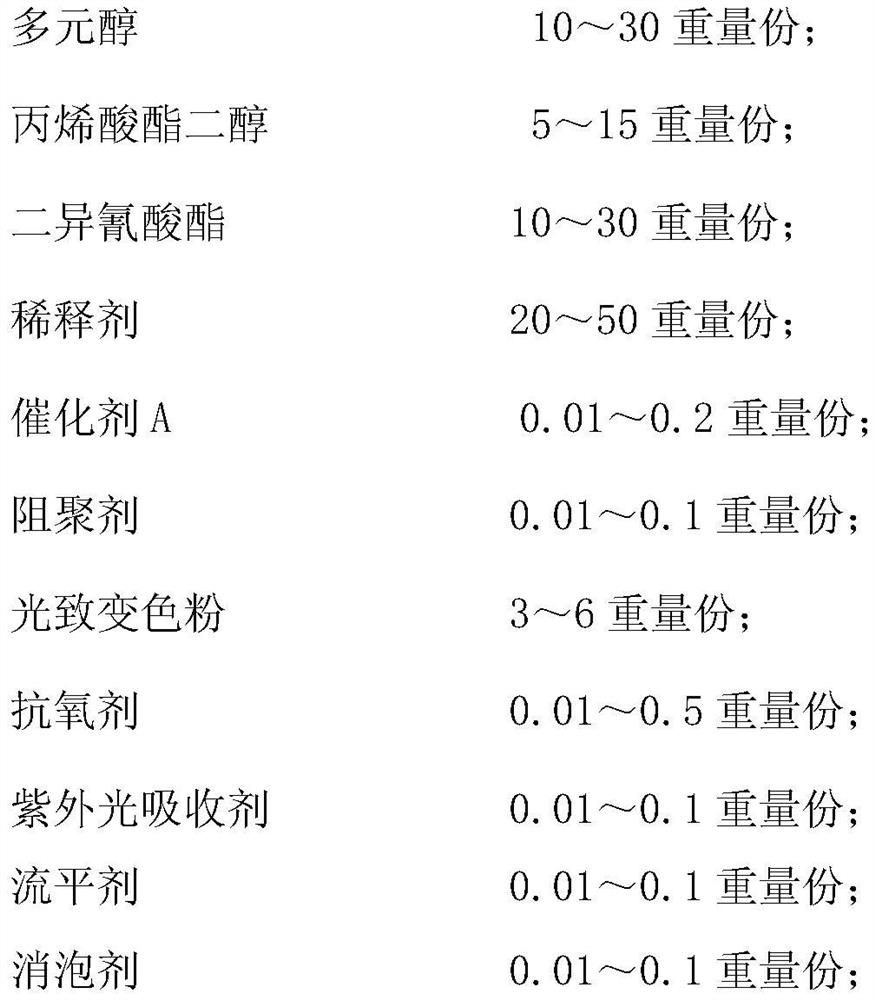

Method used

Image

Examples

Embodiment 1

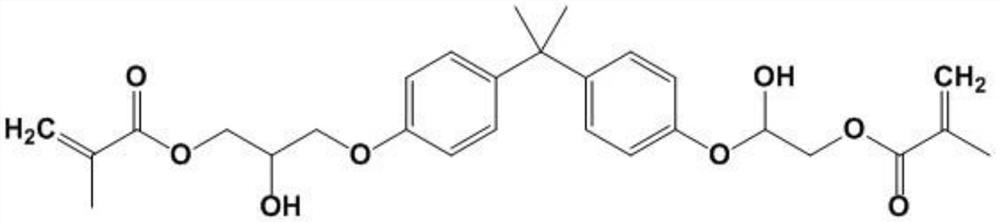

[0046] Embodiment 1 self-made acrylate diol:

[0047]Add 50g of glycidyl methacrylate, 0.05g of 4-methoxyphenol, and 0.3g of triphenylphosphine into the container, heat up to 90°C and stir evenly, then add 40.12g of bisphenol A in four times, and add all Then keep warm at 90°C and stir for 1 hour to obtain acrylate diol, the molecular formula is as follows:

[0048]

Embodiment 21

[0051] Add 26.83g PEG1000 and 1.16g CHDM to the container and stir evenly, then vacuumize at 120°C for 1h, cool down to 60°C, add 7.94g of acrylate diol prepared in Example 1, 0.2g of dibutyltin dilaurate and 50g of dimethyl carbonate, then slowly dropwise added 14.07g of HMDI, after the dropwise addition, kept stirring at 80°C for 2 hours, then added 0.02g of 4-methoxyphenol, 2.5g of midnight gray and 2.5g of misty gray, After stirring at 80°C for 1 hour, add 0.02g of 2,6-di-tert-butyl-p-cresol, 0.02g of LOWILITE234, 0.1g of Defom2700, and 0.1g of Levaslip8629, and mix uniformly to obtain a photochromic coating composition. The photochromic coating composition is sprayed on the surface of the PC lens, rotated at 800rpm for 20 seconds, and then irradiated by a 300W infrared lamp for 2 minutes. Under the protection of nitrogen, it is cured by EB, using a voltage of 100kv, and the radiation amount 20KGy, and finally get PC photochromic lenses.

Embodiment 22

[0053] Add 26.83g PEG1000 and 1.16g CHDM to the container and stir evenly, then vacuumize at 120°C for 1h, cool down to 60°C, add 7.94g of acrylate diol prepared in Example 1, 0.2g of dibutyltin dilaurate and 50g of dimethyl carbonate, then slowly dropwise added 14.07g of HMDI, after the dropwise addition, kept stirring at 80°C for 2 hours, then added 0.02g of 4-methoxyphenol, 2.5g of midnight gray and 2.5g of misty gray, After stirring at 80°C for 1 hour, add 0.02g of 2,6-di-tert-butyl-p-cresol, 0.02g of LOWILITE234, 0.1g of Defom2700, and 0.1g of Levaslip8629, and mix uniformly to obtain a photochromic coating composition. The photochromic coating composition is sprayed on the surface of the PC lens, rotated at 800rpm for 20 seconds, and then irradiated by a 300W infrared lamp for 2 minutes. Under the protection of nitrogen, it is cured by EB, using a voltage of 120kv, and the radiation amount 50KGy, and finally get PC photochromic lenses.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com