Production process of high-purity L-arginine

A production process, arginine technology, applied in the preparation of microorganisms, organic compounds, microorganism-based methods, etc., can solve the problems of affecting the product purification process, low product yield, and low clarity of feed and liquid.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Arginine fermentation process, including:

[0036] Step 1) The activated arginine producing strain Escherichia coli (Escherichia coli) CGMCCNo.11674 bacterial liquid (1×10 8 cfu / ml) was inserted into the seed tank and carried out seed culture for 24h to obtain the seed liquid. The culture temperature was 38°C, the pH was 6.8, the air volume was 200L / h, the rotating speed was 350rpm, and the tank pressure was 0.04mpa.

[0037]Step 2) Inoculate the seed liquid with 12% inoculation amount in a 100L fermenter with 50L fermentation medium for cultivation, the rotation speed is 280rpm, the temperature is 34°C, and the pH is 7.1 (pH value is controlled by adjusting the pH value through ammonia water). The pressure is 0.03mpa, the dissolved oxygen is controlled above 18% by alternately increasing the rotating speed and air volume, and the fermentation cycle is 55h.

[0038] The process of adding culture medium during fermentation is as follows:

[0039] 1) When fermenting and...

Embodiment 2

[0057] Arginine extraction process:

[0058] Step 1) Centrifugation and ceramic membrane filtration: L-arginine fermentation broth is centrifuged at a speed of 5000rpm for 3 minutes in a high-speed disc centrifuge to remove precipitates, and then filtered through a ceramic membrane with a molecular weight cut-off of 10000Da, and the filtration temperature is controlled at 60 °C , collect the filtrate.

[0059] Step 2) Passing weakly acidic cationic resin: the filtrate obtained in step 1) is adsorbed by weakly acidic cationic resin, and then eluted with ammonia water to obtain the eluent of L-arginine.

[0060] Step 3) Deamination: Concentrate the eluate obtained in step 2) by 2 times to remove the ammonia content below 0.02%, and control the temperature at 55°C-65°C.

[0061] Step 4) Decolorization of nanofiltration membrane: decolorize the eluate obtained in step 3) with a nanofiltration membrane with a molecular weight of 500Da. During the process of passing through the mem...

Embodiment 3

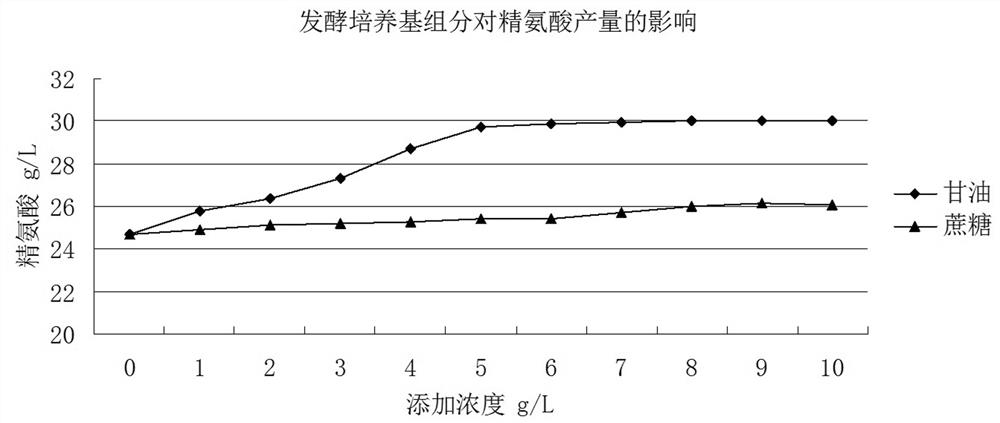

[0066] Effect of fermentation medium components on arginine production.

[0067] 1. On the basis of Comparative Document 1, additionally add different carbon sources, including sucrose and glycerol, the added concentrations are 0, 1, 2, 3, 4, 5, 6, 7, 8, 9, 10, and the unit is g / L, such as figure 1 As shown, the addition of sucrose has no obvious effect on the production of arginine, but glycerol can increase the production of arginine. With the increase of glycerol concentration, the content of arginine increases, but when the concentration increases to 5g / L, it is close to When the peak value continued to increase, the production of arginine did not change significantly. Considering factors such as yield and cost comprehensively, when the concentration of glycerin is 5g / L, it is the optimal amount to add.

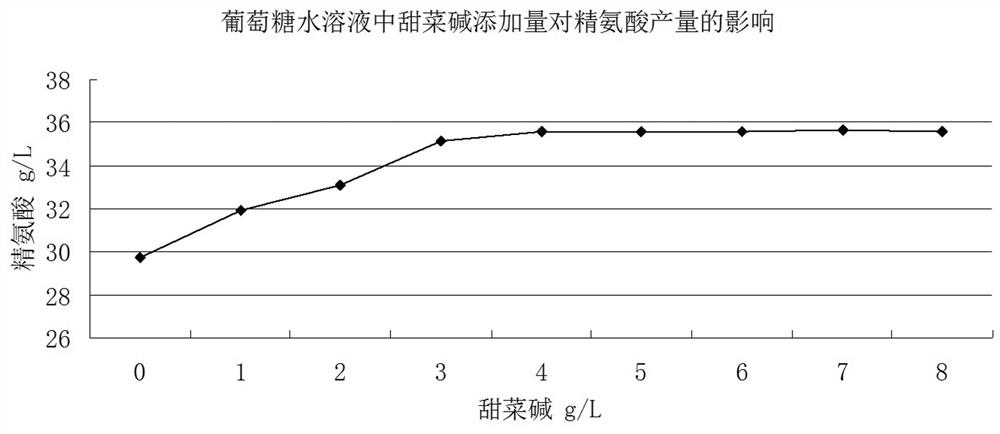

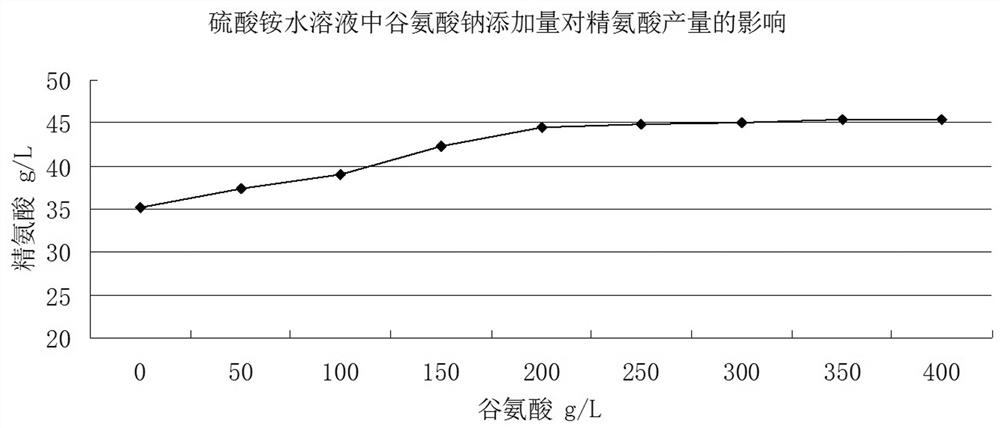

[0068] 2. To verify the effect of the amount and composition of glucose aqueous solution on the acid production of arginine.

[0069] Experiments were conducted to ve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com