Reversible double-superaffinity film and its preparing process and application

An amphiphilic and reversible technology, applied in the direction of coating, etc., can solve the problems of easy condensation or agglomeration of nanoparticles, low heat treatment temperature, single induction method, etc., and achieve the effect of improving light transmission, uniform dispersion, and avoiding agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] (1) At room temperature, 1.6 mol of tetrabutyl titanate, 0.1 mol of tin tetrachloride, 0.2 mol of zinc chloride, and 0.1 mol of tungsten hexachloride (at this moment, tetrabutyl titanate accounts for 80% of the total metal salt ), joined in the ethanol solvent of 97.3mol, after the metal salt was dispersed evenly with ultrasonic waves, a transparent sol was obtained;

[0055] (2) Add 0.1 mol of stabilizer glycerin to the obtained transparent sol, slowly add 35% of 0.06 mol concentrated hydrochloric acid catalyst dropwise under strong stirring, and continue stirring for about 0.1 hour to generate a mixture containing partially hydrolyzed metal salts;

[0056] (3) aging the above mixture for 3 hours to obtain a transparent sol with evenly dispersed nanoparticles;

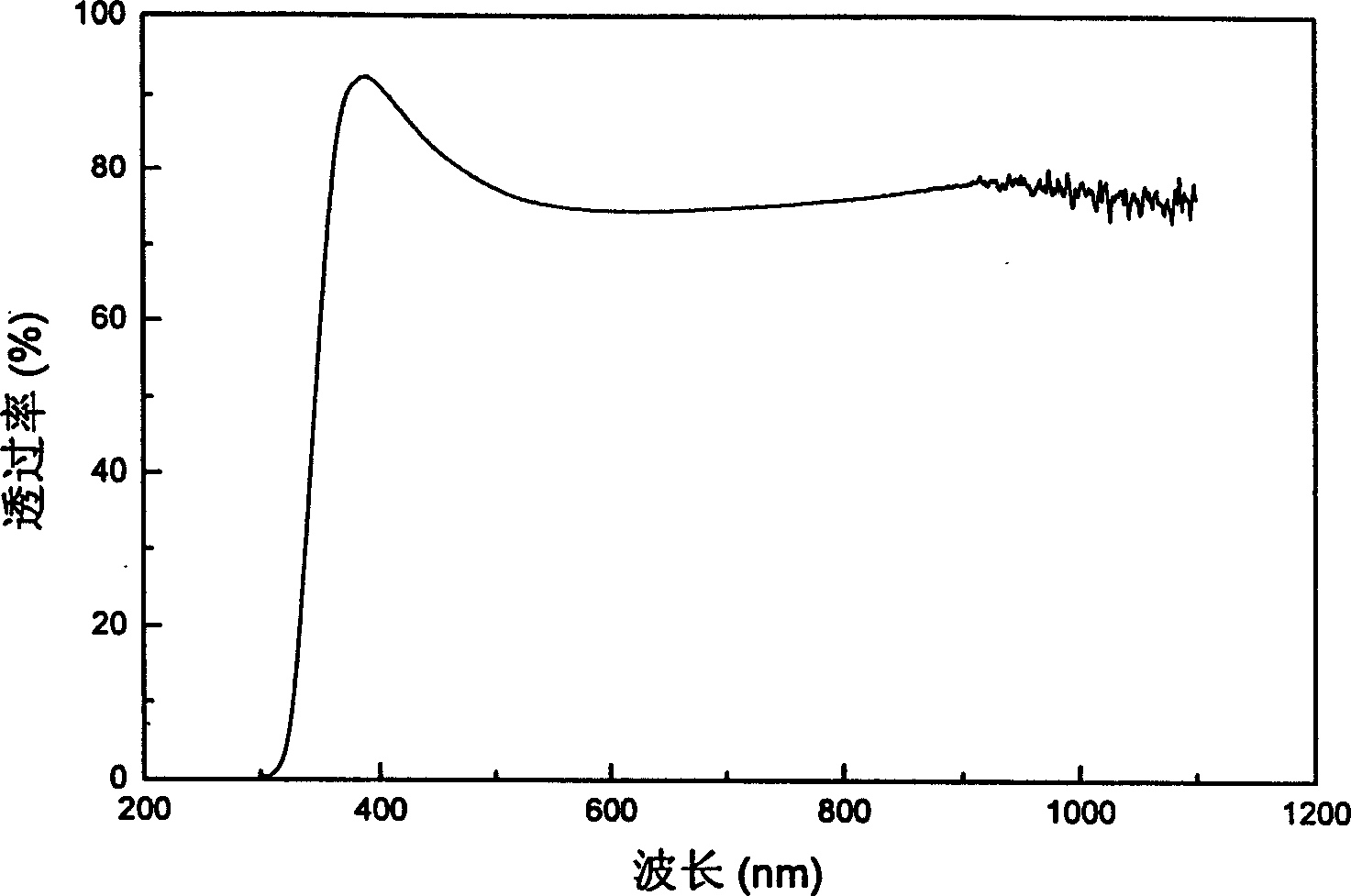

[0057] (4) Spin-coat the above-mentioned transparent sol on a glass sheet to make a film, dry it at room temperature, place it in a muffler furnace at 550° C., and keep it warm for 1.5 hours to obtain a transpa...

Embodiment 2

[0062] (1) At room temperature, add 9 mol of tetrabutyl titanate, 0.7 mol of zinc acetate, 0.2 mol of strontium dichloride hexahydrate, and 0.1 mol of ammonium molybdate (at this time, tetrabutyl titanate accounts for 90% of the total metal salt) , was added to 88.1mol of acetone solvent, and the metal salt was uniformly dispersed by ultrasonic waves to obtain a transparent sol;

[0063] (2) Add 1.8 mol of ethylene glycol stabilizer to the obtained transparent sol, slowly add 0.1 mol of acetic acid catalyst dropwise under strong stirring, and continue to stir for about 0.5 hours to generate a mixture containing partially hydrolyzed metal salts;

[0064] (3) aging the above mixture for 4 hours to obtain a transparent sol with evenly dispersed nanoparticles;

[0065] (4) The above-mentioned transparent sol is spin-coated on a glass sheet to form a thin film, and after drying at room temperature, it is placed in a muffler furnace at 600° C. and kept for 0.3 hours to obtain a tran...

Embodiment 3

[0069] (1) At room temperature, add 27.71 mol of tetrabutyl titanate, 2 mol of tin acetate, 1 mol of basic aluminum acetate dihydrate, 0.89 mol of ammonium molybdate, and 1 mol of niobium pentachloride (at this time, tetrabutyl titanate accounts for the total amount of metal salt) 85% of the amount), was added in the ethanol solvent of 60.4mol, and after the metal salt was dispersed uniformly by ultrasonic waves, a transparent sol was obtained;

[0070] (2)) Add 5.4mol of 1,3-propanediol stabilizer to the obtained transparent sol, slowly add 35% of 1.63mol of concentrated hydrochloric acid catalyst dropwise under vigorous stirring, and continue stirring for about 1 hour to form a partially hydrolyzed mixtures of metal salts;

[0071] (3) aging the above mixture for 3.5 hours to obtain a transparent sol with evenly dispersed nanoparticles;

[0072] (4) The above-mentioned transparent sol is spin-coated on a glass sheet to form a film, and after drying at room temperature, it i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com