Galanthamine pamoate sustained-release microspheres for injection and preparation method thereof

A technology of galantamine pamoate and pamoic acid, which is applied in the field of drug sustained-release preparations, and can solve the problems of unfavorable process scale-up application, nozzle clogging, low drug loading and encapsulation efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

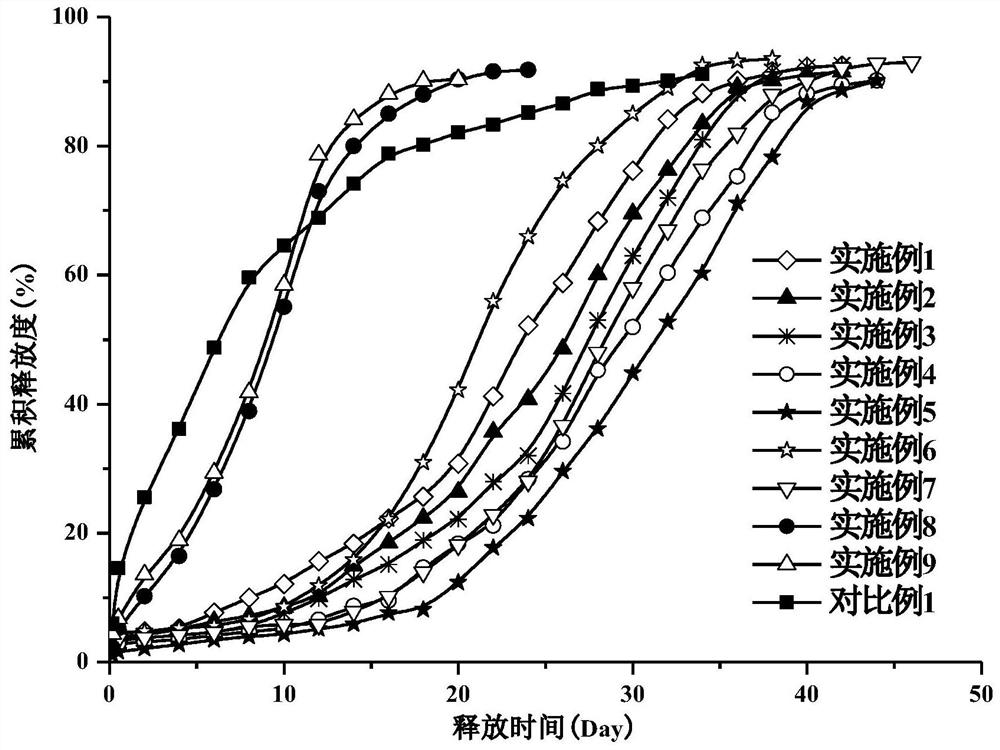

Examples

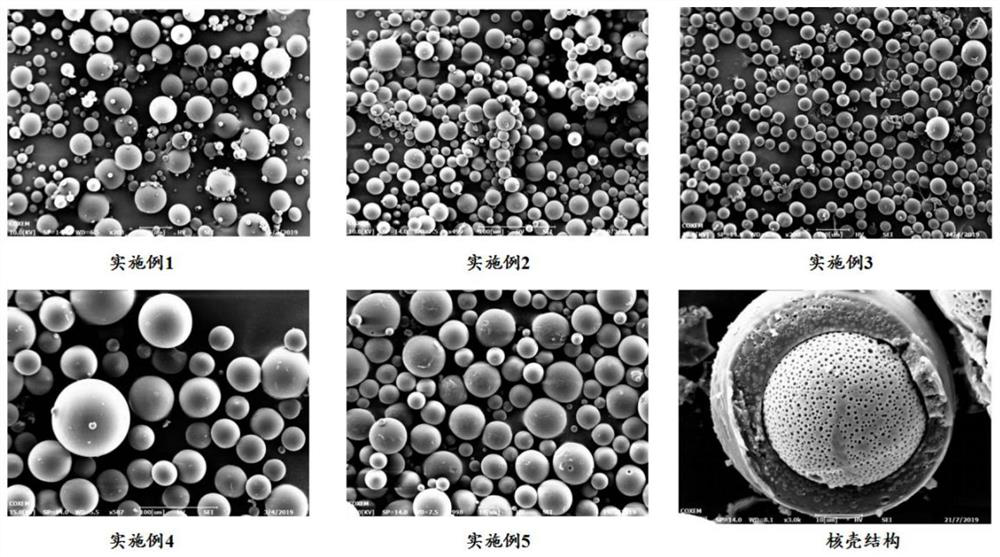

Embodiment 1~5

[0045] Examples 1-5: Preparation of microspheres with different theoretical drug loadings

[0046] Table 1. The formulations and preparation process parameters of microspheres with different drug loadings

[0047]

[0048] Preparation:

[0049] The PLGA and galanthamine pamoate were weighed respectively, stirred and dissolved in 4mL of benzyl alcohol-dichloromethane mixed solvent to prepare the continuous phase, the concentration of PLGA in the continuous phase was 300mg / mL. Weigh 6.400g of PVA and add it to 500mL water for injection (100°C), stir until dissolved, cool the PVA solution to 25°C, add water for injection to 800mL, and make 8mg / mL PVA solution to obtain the dispersed phase. Slowly add the continuous phase to the dispersed phase, and homogeneously emulsify at 3000rpm for 1min; after the emulsification is complete, turn on the mechanical stirring to evaporate the solvent, and stop stirring after 3h; filter and collect the microspheres in 800mL of poloxamer ethan...

Embodiment 6

[0052] Prescription and preparation process parameters:

[0053]

[0054] Preparation:

[0055] Weigh PLGA and galanthamine pamoate respectively according to the prescription amount, stir and dissolve in 4.8mL benzyl alcohol-dichloromethane mixed solvent to prepare a continuous phase, the concentration of PLGA in the continuous phase is 250mg / mL. Weigh 8.000g of PVA and add it to 500mL water for injection (100°C), stir until dissolved, cool the PVA solution to 25°C, add water for injection to 800mL, and make a 10mg / mL PVA solution to obtain a dispersed phase. Slowly add the continuous phase to the dispersed phase, and homogeneously emulsify at 2000rpm for 1min; after the emulsification is completed, turn on the mechanical stirring to evaporate the solvent, and stop stirring after 3h; filter and collect the microspheres in 800mL of poloxamer ethanol aqueous solution, continue to stir for 1h, and The resulting suspension was filtered through a -100 mesh to +600 mesh screen t...

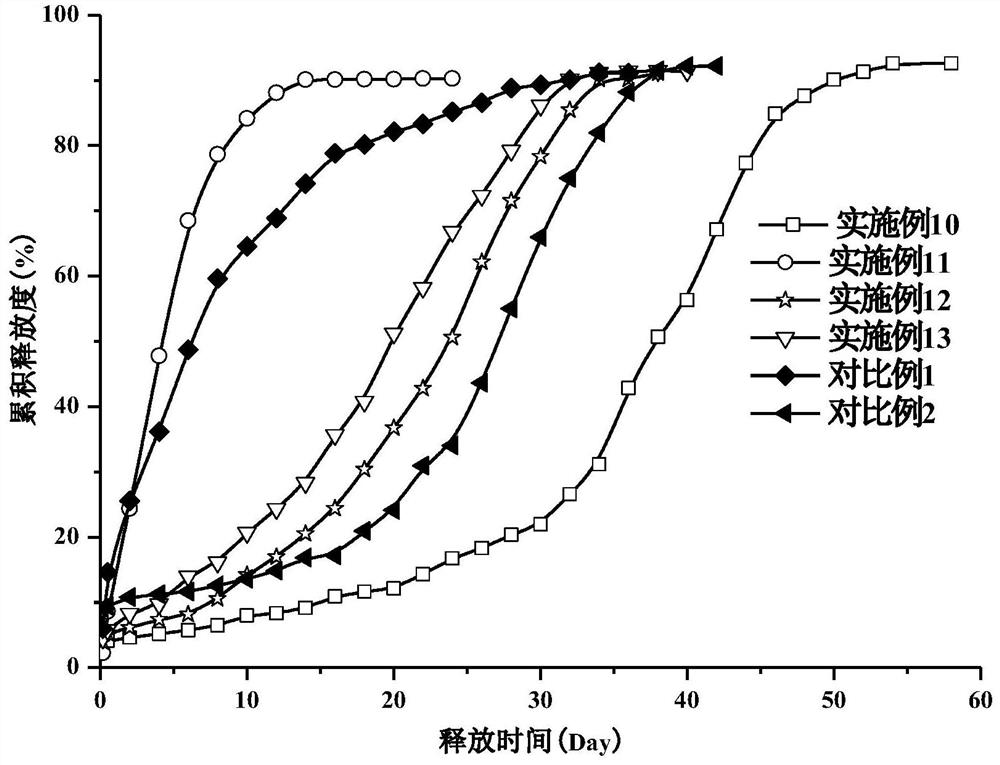

Embodiment 7

[0058] Prescription and preparation process parameters:

[0059]

[0060]

[0061] Preparation:

[0062] Weigh PLGA and galantamine pamoate respectively according to the prescription amount, stir and dissolve in 6mL benzyl alcohol-ethyl acetate mixed solvent to prepare a continuous phase, the concentration of PLGA in the continuous phase is 200mg / mL. Weigh 24.000g of PVA and add it to 500mL water for injection (100°C), stir until dissolved, cool the PVA solution to 25°C, add water for injection to 800mL, and make a 20mg / mL PVA solution to obtain a dispersed phase. Slowly add the continuous phase to the dispersed phase, and homogeneously emulsify at 4000rpm for 1min; after the emulsification is complete, turn on mechanical stirring to evaporate the solvent, and stop stirring after 3h; filter and collect the microspheres in 800mL polysorbate 80 ethanol aqueous solution, continue stirring for 1h, and The resulting suspension was filtered through a -100 mesh to +600 mesh sc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com