Piglet yoghurt diluted in low proportion as well as preparation method and use method of piglet yoghurt

A low-proportion, piglet technology, applied in the field of pig feed, can solve the problems of uneasy acceptance by breeders, low dry matter intake, and unfavorable rapid growth of pigs, so as to inhibit bacterial growth, increase intake, and promote piglets. effect of growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

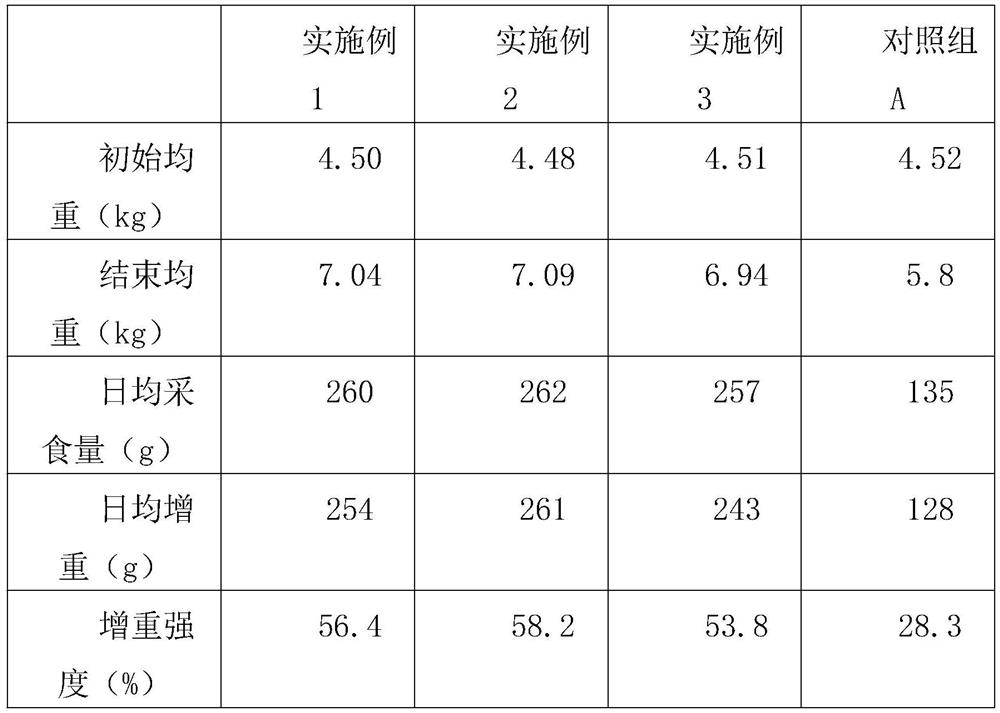

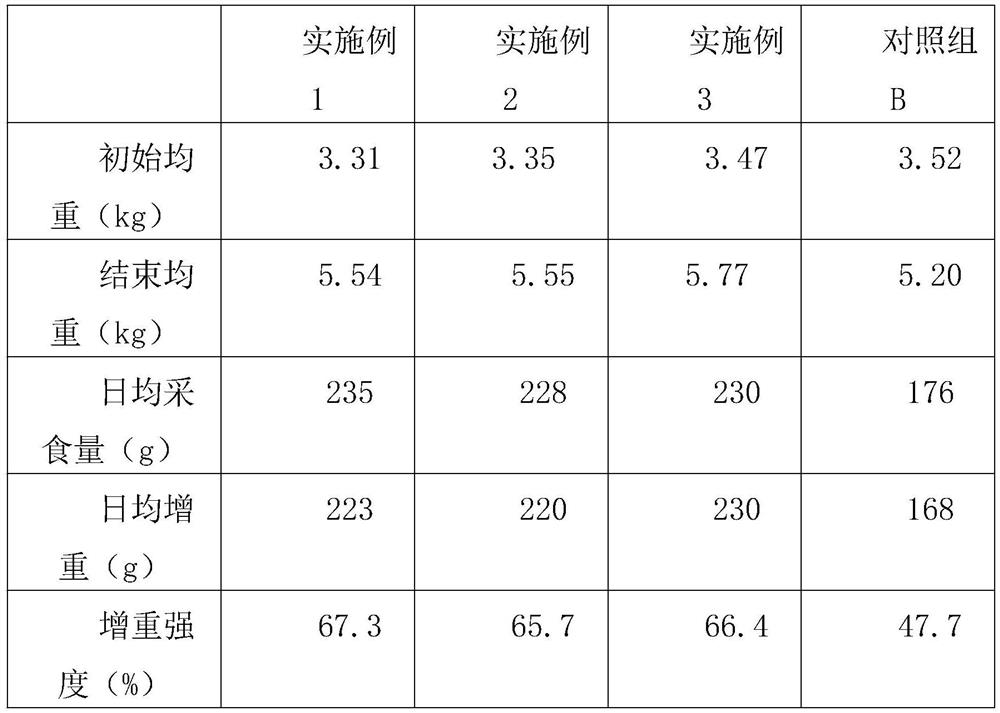

Examples

Embodiment 1

[0026] Weighing by batching scale: 250kg citric acid, 250kg benzoic acid, 250kg malic acid and 250kg sorbic acid, put the above four acidifying agents into a 1000kg horizontal stainless steel mixer and mix uniformly to make a compound acid premix, Packed into 12kg / bag for later use, this compound acidifier is added by 12kg / ton, converted into formula weight percentage is: citric acid 0.3%, benzoic acid 0.3%, malic acid 0.3%, sorbic acid 0.3%.

[0027] Weighing by batching scale: lysine 99kg, threonine 66kg, methionine 66kg, tryptophan 49.5kg, isoleucine 33kg, valine 49.5kg, calcium dihydrogen phosphate 231kg, calcium formate 132kg, sodium alginate 161.7kg, carboxymethyl cellulose 66kg, multivitamin 13.2kg, Brady’s yeast 6.6kg and antioxidant 16.5kg, mix the above-mentioned raw materials of 993.3kg in total to make a compound organic premix, and pack it into 30kg / The package is spare, this organic compound package is added at 30kg / ton, converted into the weight percentage of t...

Embodiment 2

[0030]Weighing by batching scale: 320kg citric acid, 160kg benzoic acid, 320kg malic acid and 160kg sorbic acid, put the above four acidifying agents into a 1000kg horizontal stainless steel mixer and mix uniformly to make a compound acid premix, Packed into 12kg / bag for later use, this compound acidifier is added by 12kg / ton, converted into formula weight percentage is: citric acid 0.4%, benzoic acid 0.2%, malic acid 0.4%, sorbic acid 0.2%.

[0031] Weighing by batching scale: lysine 120kg, threonine 84kg, methionine 75kg, tryptophan 60kg, isoleucine 30kg, valine 36kg, calcium dihydrogen phosphate 240kg, calcium formate 126kg, sodium alginate 120kg, 66kg of carboxymethyl cellulose, 9kg of multivitamins, 6kg of Brady’s yeast and 18kg of antioxidants. Mix the above-mentioned 999kg of raw materials evenly to make a compound organic premix, which is packed into 33kg / bag for later use. This organic compound package Added at 33kg / ton, converted into formula weight percentage: 0.4% ...

Embodiment 3

[0034] Weighing by batching scale: 320kg citric acid, 160kg benzoic acid, 240kg malic acid and 240kg sorbic acid, put the above four acidifying agents into a 1000kg horizontal stainless steel mixer and mix uniformly to make a compound acid premix, Packed into 12kg / bag for later use, this compound acidifier is added by 12kg / ton, converted into formula weight percentage is: citric acid 0.4%, benzoic acid 0.2%, malic acid 0.3%, sorbic acid 0.3%.

[0035] Weighing by batching scale: lysine 126kg, threonine 90kg, methionine 72kg, tryptophan 57kg, isoleucine 30kg, valine 39kg, calcium dihydrogen phosphate 225kg, calcium formate 123kg, sodium alginate 126kg, 69kg of carboxymethyl cellulose, 12kg of multivitamins, 6kg of Brady’s yeast and 15kg of antioxidants. Mix the above-mentioned 990kg of raw materials evenly to make a compound organic premix, which is packed into 33kg / bag for later use. This organic compound package Added at 33kg / ton, converted into formula weight percentage: 0.4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com