Superhard multi-component boride particle reinforced aluminum-based composite material and preparation method thereof

A technology of boride particles and composite materials, which is applied in the field of superhard multi-component boride particles reinforced aluminum-based composite materials and its preparation, can solve the problems of high-entropy boride ceramics, such as difficulty in sintering and densification, long preparation cycle, and low density. , to achieve the effect of high utilization rate of raw materials, good wettability and high interface bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033]Step 1, weighing: prepare the required raw materials according to the following mass percentages: industrial pure aluminum 84.15, Al-1B master alloy 15, high-purity transition metal elements Hf, Ta, Zr, Nb, Ti single mass block with a molar ratio of 0.2 :0.2:0.2:0.2:0.2:1, its total mass percentage is 0.85.

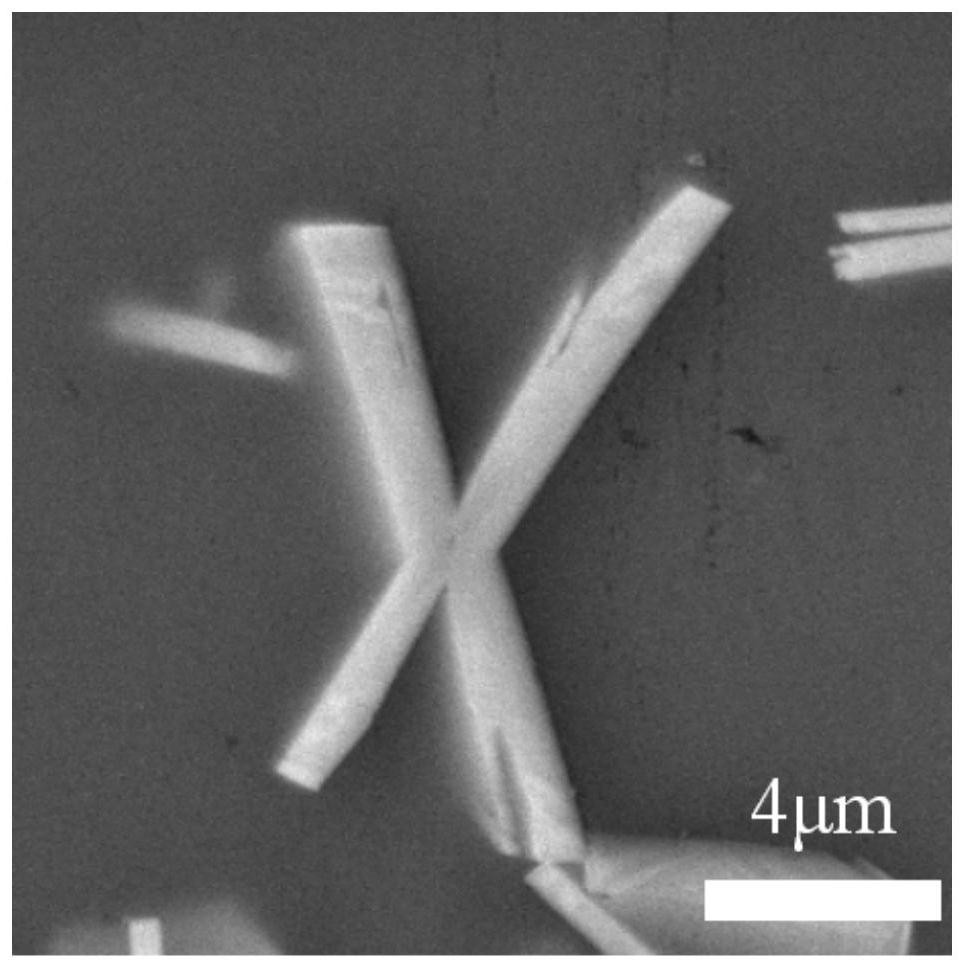

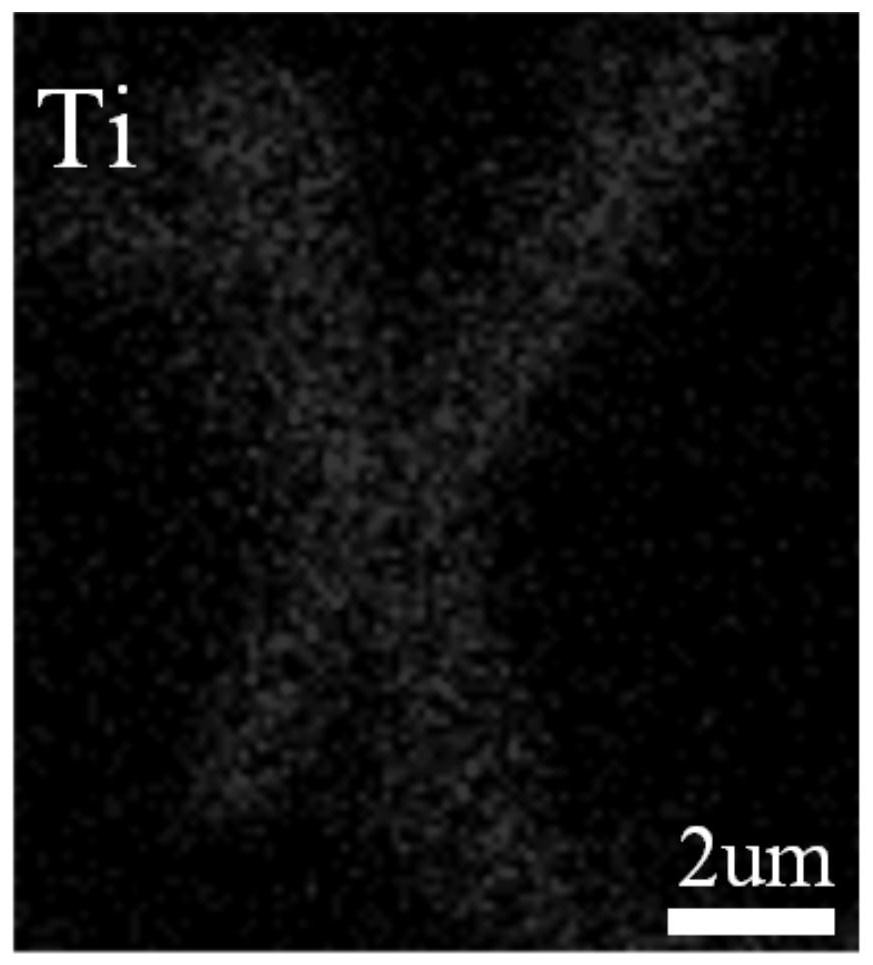

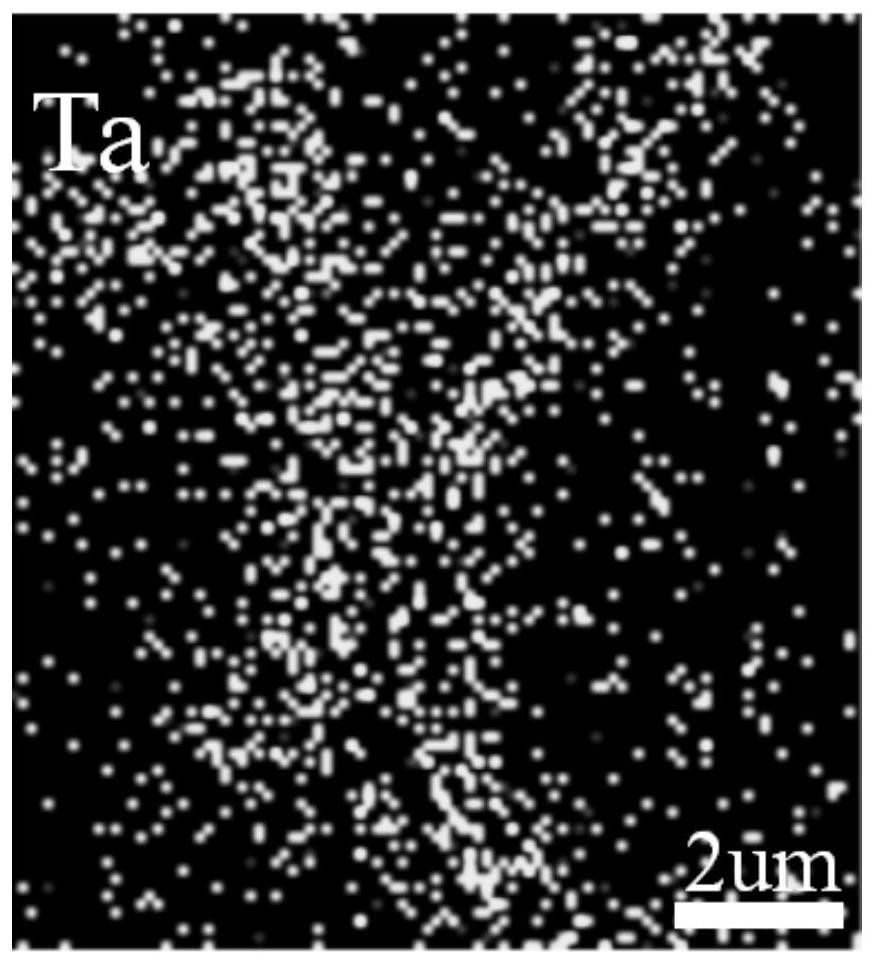

[0034] Step 2, smelting: use a vacuum arc melting furnace to prepare superhard (Hf 0.2 Ta 0.2 Zr 0.2 Nb 0.2 Ti 0.2 )B 2 Multi-component boride particle reinforced aluminum matrix composites.

[0035] 1) Put the weighed pure aluminum and Hf, Ta, Zr, Nb, Ti into the water-cooled copper crucible of the vacuum electric arc furnace according to the melting point from low to high, and place a pure titanium block in the other crucible.

[0036] 2) Vacuum to 1×10 -5 Pa, then pass through the argon protective gas to 4×10 2 Pa. Turn on the smelting DC power switch, first smelt pure Ti blocks to absorb the remaining oxygen in the furnace cavity, then smelt pure alumin...

Embodiment 2

[0040] Step 1, weighing: prepare the required raw materials according to the following mass percentages: industrial pure aluminum 80.60, Al-3B master alloy 16.67, and the molar ratio of high-purity transition metal elements Hf, Ta, Zr, Nb, Ti single mass block is 0.2 :0.2:0.2:0.2:0.2:1, its total mass percentage is 2.73.

[0041] Step 2, smelting: use a vacuum arc melting furnace to prepare superhard (Hf 0.2 Ta 0.2 Zr 0.2 Nb 0.2 Ti 0.2 )B 2 Multi-component boride particle reinforced aluminum matrix composites.

[0042] 1) Put the weighed pure aluminum and Hf, Ta, Zr, Nb, Ti into the water-cooled copper crucible of the vacuum electric arc furnace according to the melting point from low to high, and place a pure titanium block in the other crucible.

[0043] 2) Vacuum to 1×10 -5 Pa, then pass through the argon protective gas to 4×10 2 Pa. Turn on the smelting DC power switch, first smelt pure Ti blocks to absorb the remaining oxygen in the furnace cavity, and then smelt...

Embodiment 3

[0047] Step 1, weighing: Prepare the required raw materials according to the following mass percentages: industrial pure aluminum 61.21, Al-3B master alloy 33.33, and the molar ratio of high-purity transition metal elements Hf, Ta, Zr, Nb, and Ti elemental block is 0.2 :0.2:0.2:0.2:0.2:1, and its total mass percentage is 5.46 respectively.

[0048] Step 2, smelting: use a vacuum arc melting furnace to prepare superhard (Hf 0.2 Ta 0.2 Zr 0.2 Nb 0.2 Ti 0.2 )B 2 Multi-component boride particle reinforced aluminum matrix composites.

[0049] 1) Put the weighed pure aluminum and Hf, Ta, Zr, Nb, Ti into the water-cooled copper crucible of the vacuum electric arc furnace according to the melting point from low to high, and place a pure titanium block in the other crucible.

[0050] 2) Vacuum to 1×10 -5 Pa, then pass through the argon protective gas to 4×10 2 Pa. Turn on the smelting DC power switch, first smelt pure Ti blocks to absorb the remaining oxygen in the furnace cav...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com