Alpha-MnSe nanosheet and preparation method and application thereof

A nanosheet and square technology, applied in the field of α-MnSe nanosheets and their preparation, can solve the problems of poor control of the thickness, size and mass production of two-dimensional nanosheets, limit the exploration and practical application of basic properties, etc., and achieve excellent light detection. The effect of high performance, fast synthesis speed and high crystallization quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] This embodiment provides an α-MnSe(001) square nanosheet, and the preparation method of the α-MnSe(001) square nanosheet includes the following steps:

[0054] Place the Se powder in the low temperature zone of the dual temperature zone tube furnace, MnO 2 The powder is placed in the high temperature zone of the dual temperature zone tube furnace, and the mica substrate is placed in the MnO 2 At 2 to 6 cm behind the powder, after cleaning the quartz tube with argon, raise the temperature in the low-temperature zone to 280°C, and the temperature in the high-temperature zone to 720°C; continue to feed the mixed gas of argon and hydrogen, and the flow rate of argon The growth time is 120 sccm, the flow rate of hydrogen is 10 sccm, the growth time is 30 min, and then naturally cooled to room temperature.

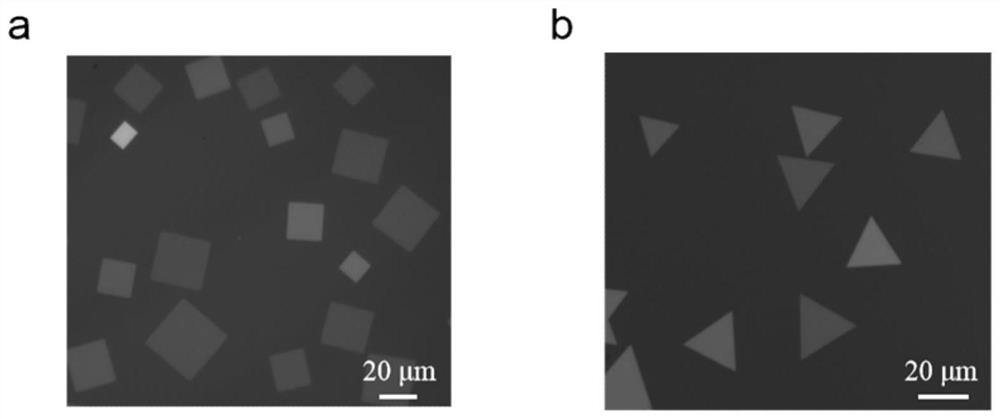

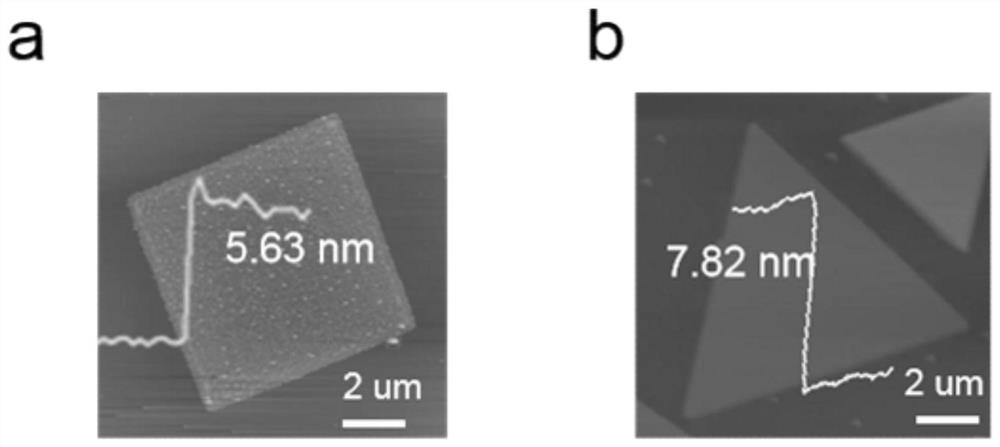

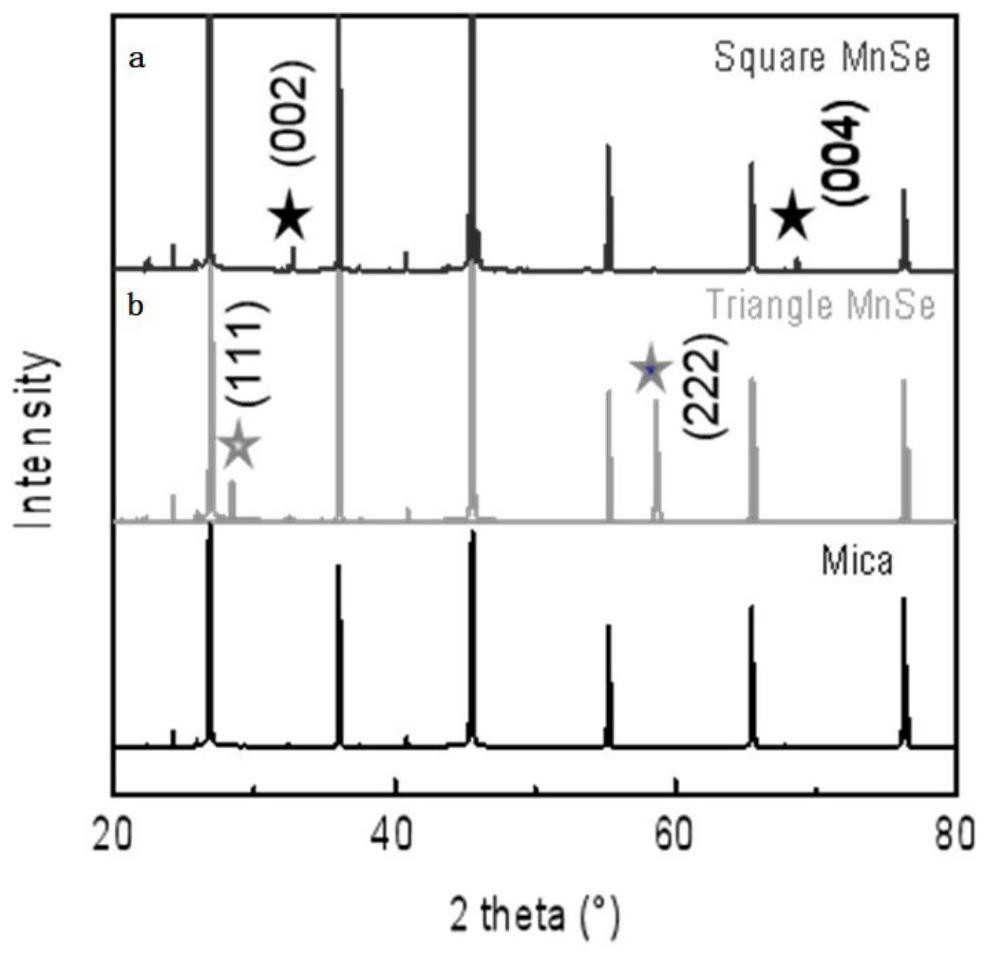

[0055] specifically, figure 1 a is an optical microscope (OM) image of α-MnSe(001) square nanosheets grown on a mica substrate; figure 2 a is the atomic force microsc...

Embodiment 2

[0060] This embodiment provides a kind of α-MnSe(111) triangular nanosheet, the preparation method of the α-MnSe(111) triangular nanosheet includes the following steps:

[0061] Place the Se powder in the low temperature zone of the dual temperature zone tube furnace, MnCl 2 The powder is placed in the high temperature zone of the dual temperature zone tube furnace, and the mica substrate is placed in the MnCl 2 At 2 to 6 cm behind the powder, after cleaning the quartz tube with argon, raise the temperature in the low-temperature zone to 280°C, and the temperature in the high-temperature zone to 660°C, and continuously feed the mixed gas of argon and hydrogen. Among them, the flow rate of argon 100-150 sccm, the hydrogen flow rate is 5-20 sccm, the growth time is 15-50 min, and then naturally cooled to room temperature.

[0062] specifically, figure 1 b is an optical microscope (OM) image of α-MnSe(111) triangular nanosheets grown on a mica substrate, figure 2 b is the ato...

Embodiment 3

[0067] In this example, the α-MnSe nanosheets of Examples 1 and 2 were made into transistor devices through EBL and thermal evaporation processes, and their performance in photodetection was tested. The laser wavelength used was 473nm.

[0068] specifically, Figure 8 a is the output characteristic curve of the photodetector of α-MnSe(001) square nanosheets under different laser intensities, Figure 7 A device diagram based on α-MnSe(001) square nanosheets, thermally evaporated Cr / Au(8 / 60nm) as source and drain electrodes; by Figure 7 and Figure 8 a It can be seen that the α-MnSe(001) square nanosheets exhibit obvious photoresponse after adding light. Figure 8 b is the optical switching characteristics of the α-MnSe photodetector under different light intensities, given by Figure 8 b It can be seen that the device has good stability. Figure 8 c is the photodetection responsivity of α-MnSe(001) square nanosheets, given by Figure 8 c It can be seen that α-MnSe(001) sq...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Biggest size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com