Preparation method of titanium selenide nanowire

A nanowire and titanium selenide technology, which is applied in the field of preparation of titanium selenide nanowires, can solve the problems of high reaction temperature, long time consumption, and difficult control, and achieve the effects of simple preparation process, high repeatability, and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

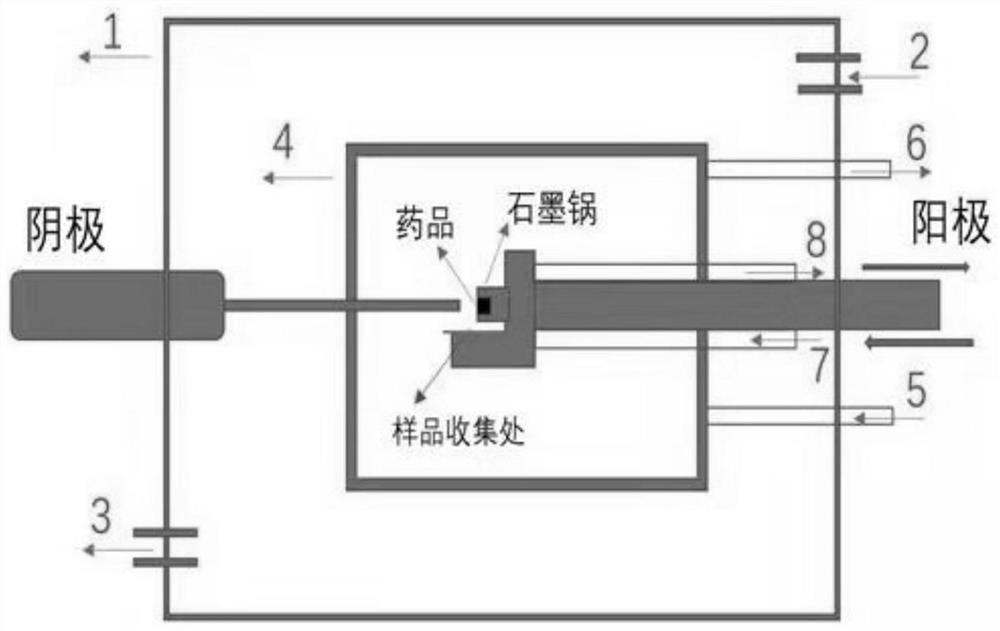

Method used

Image

Examples

Embodiment 2

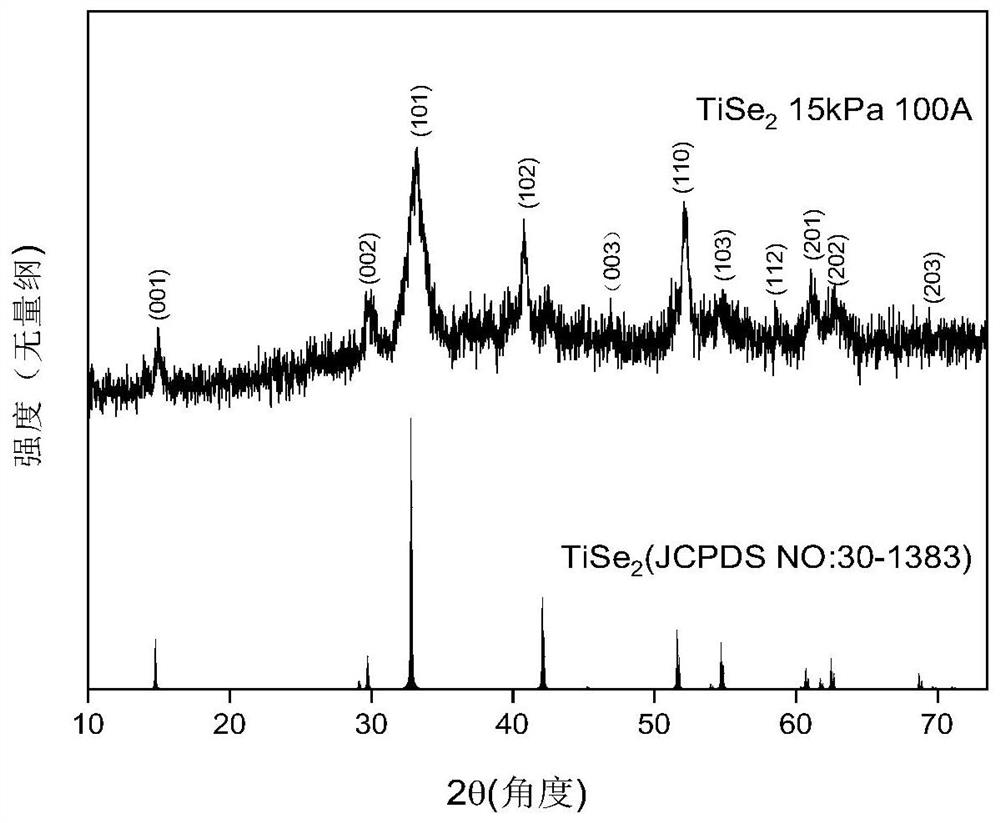

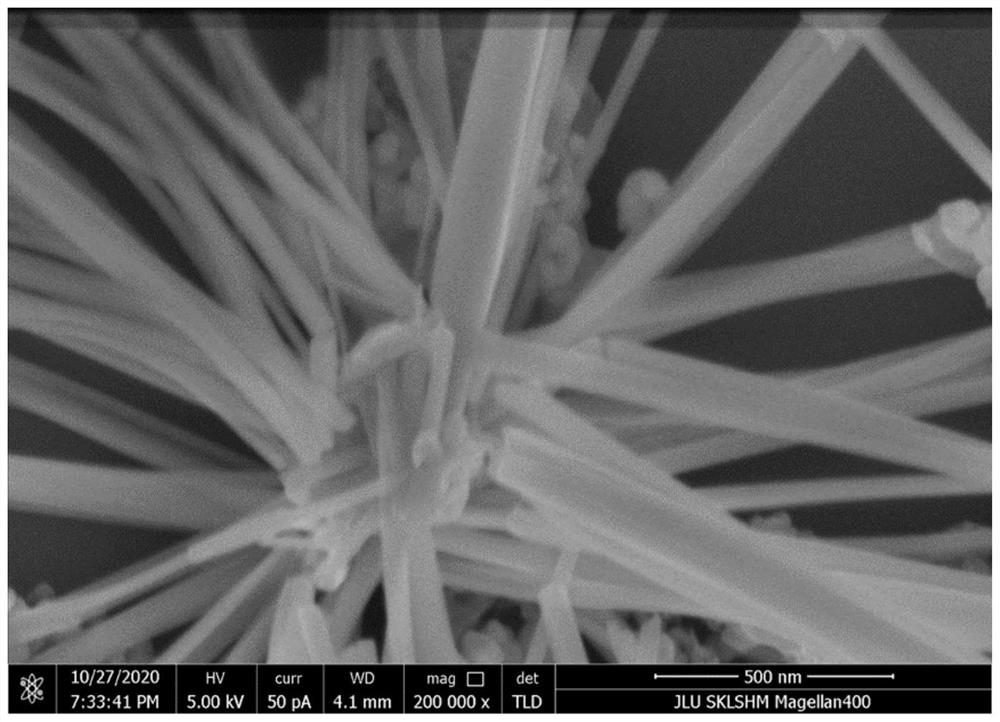

[0020] Example 2TiSe 2 Preparation of nanowires

[0021] Weigh 0.2308g of titanium powder and 0.7584g of selenium powder according to the molar ratio of 1:2, add a little absolute ethanol to grind, and mix the two evenly. The ground mixture was put into a tablet machine mold, and compressed into cylindrical flakes with a height of 3 mm and a diameter of 1 cm. Place the disk into a horizontal anode graphite pot, fixed to one side inside the device. The cathode tungsten rod is fixed on the other side of the reaction device, coincident with the horizontal axis of the anode graphite pot, and the distance between the cathode and anode is adjusted to about 1cm. Close the reaction device, and pump the air pressure in the device to below 10Pa after washing. Under the protection of water cooling system and argon atmosphere, the pressure in the device was raised to 15kPa. Turn on the arcing power supply, set the reaction current to 100A, perform arcing discharge, and stop the discha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com