A cobalt-based polymetallic single-atom isomorphously substituted phosphorus-aluminum molecular sieve meapo-5 and its preparation method

A phospho-aluminum molecular sieve and isomorphous substitution technology, which is applied in molecular sieve compounds, molecular sieve-specific aluminum phosphate, molecular sieve and alkali-exchanged phosphate, etc., can solve the problems of application limitation, lack of active sites of phospho-aluminum molecular sieve, etc., and achieves simple process operation. , Conducive to product diffusion, the effect of strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

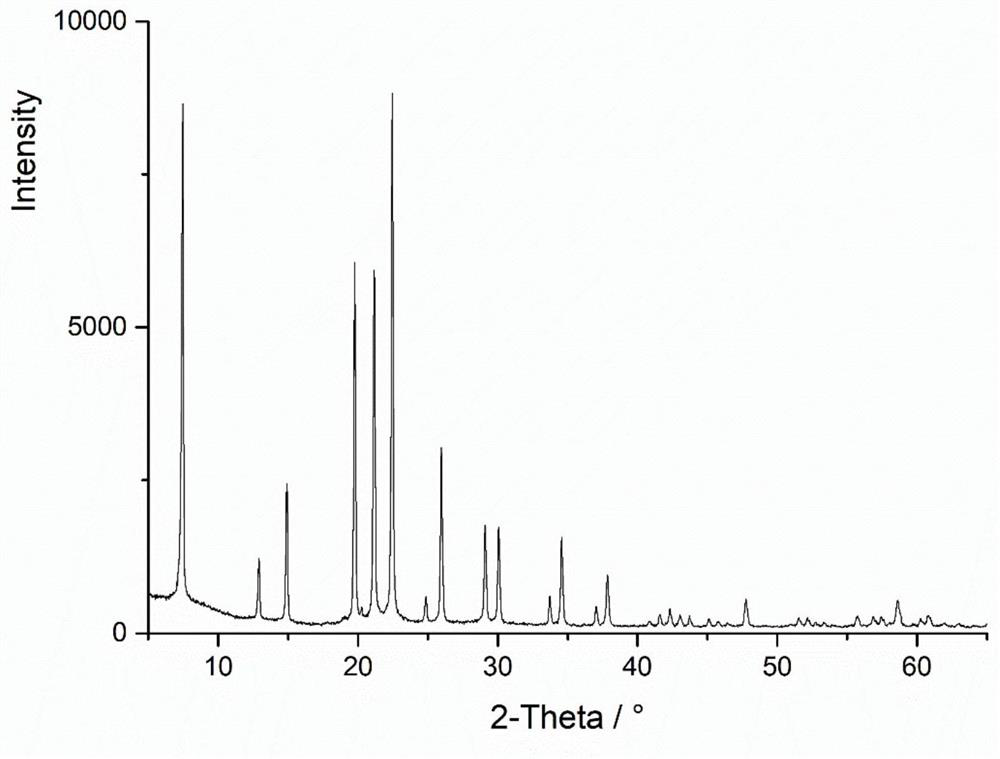

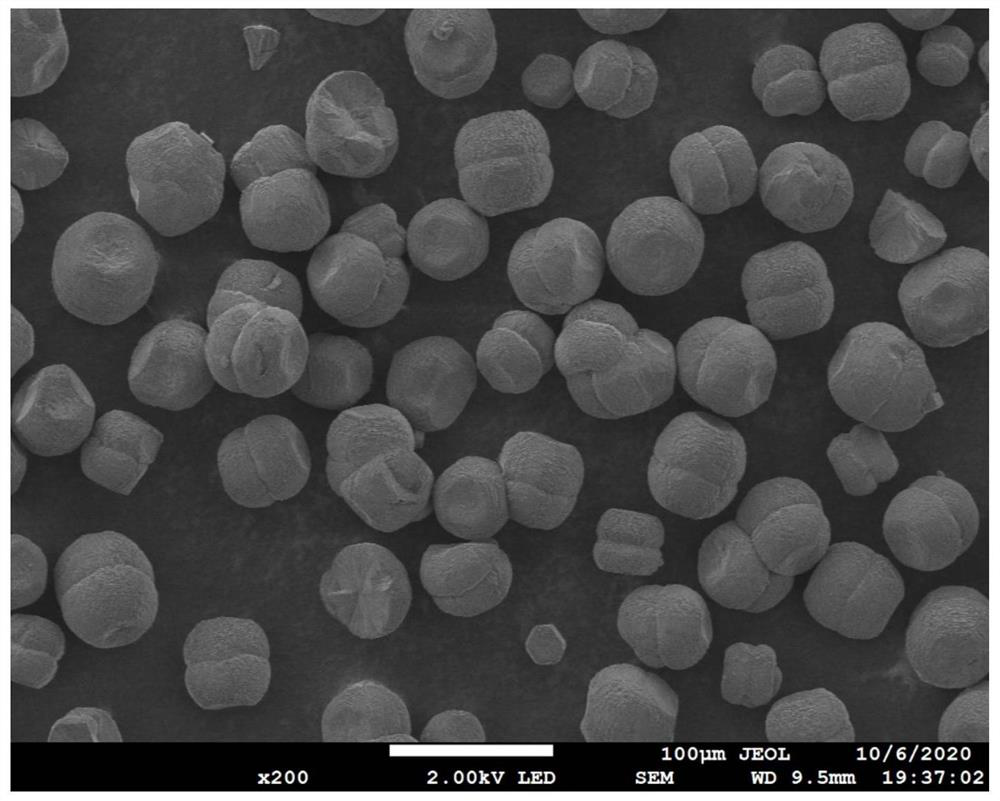

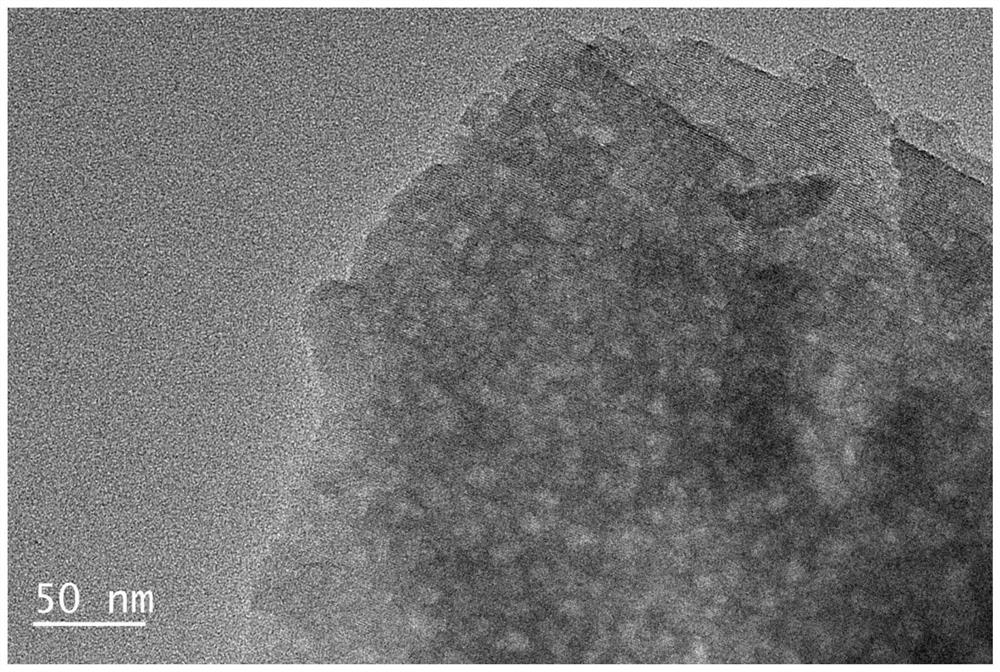

Image

Examples

Embodiment 1

[0038] Mix pseudoboehmite, orthophosphoric acid, cobalt nitrate, yttrium nitrate, triethylamine, hydrofluoric acid and deionized water evenly, and the corresponding molar ratio is 1:1.31:0.08:0.009:0.75:0.05:30.00; The sequence is: 50% deionized water & phosphorus source - aluminum source - doped metal mixture - template agent. The preparation of the crystallization solution is as follows: take 30% deionized water and fully mix it with the calculated amount of hydrofluoric acid to form solution A; take another 20% deionized water, add the calculated amount of cobalt nitrate and yttrium nitrate, fully mix, and prepare It is solution B; under the condition of maintaining vigorous stirring, slowly drop solution B into solution A; fully stir until a uniform liquid mixture without precipitation is formed. During the preparation process, it is necessary to ensure that the temperature of the liquid is lower than 15°C; Slowly drop the mixture into the pre-mixed slurry of pseudo-boehmi...

Embodiment 2

[0041] Mix aluminum hydroxide, orthophosphoric acid, cobalt nitrate, tantalum nitrate, tri-n-propylamine, hydrofluoric acid and deionized water evenly, and the corresponding molar ratio is 1:1.21:0.05:0.01:0.5:0.01:43.00; crystallization The preparation of the solution is as follows: take 30% deionized water, fully mix it with the calculated amount of hydrofluoric acid, and make solution A; take another 20% deionized water, add the calculated amount of cobalt nitrate, mix it fully, and prepare it as solution B; Under the condition of maintaining vigorous stirring, slowly drop solution B into solution A; after that, add the calculated amount of tantalum nitrate, and stir fully until a uniform liquid mixture without precipitation is formed. During the preparation process, it is necessary to ensure that the liquid temperature is lower than 15 ℃; then slowly drop this liquid mixture into the slurry formed by the pre-mixing of aluminum hydroxide and orthophosphoric acid; then add th...

Embodiment 3

[0044] Mix SB powder, orthophosphoric acid, cobalt nitrate, zirconium nitrate, hafnium oxynitrate, (triethylamine + tri-n-propylamine), hydrofluoric acid and deionized water evenly, and the corresponding molar ratio is 1:1.57:0.01:0.01: 0.02: 0.5: 0.02: 28.00, the molar ratio of triethylamine to tri-n-propylamine is 0.42; the crystallization solution is prepared as follows: take 30% deionized water and fully mix it with the calculated amount of hydrofluoric acid to form solution A; Take 20% deionized water, add the calculated amount of cobalt nitrate and zirconium nitrate, mix thoroughly, and prepare solution B; under the condition of maintaining vigorous stirring, slowly drop solution B into solution A; after that, add the calculated amount Hafnium oxynitrate, fully stirred until a uniform liquid mixture without precipitation is formed. During the preparation process, it is necessary to ensure that the liquid temperature is lower than 15°C; then slowly drop this liquid mixture...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com