A fully premixed water-cooled combustion shell-type gas boiler

A gas-fired boiler, fully premixed technology, applied in the direction of burner, combustion type, combustion method, etc., can solve the problems of not paying attention to the arrangement, layout, rationality and mutual cooperation, increasing the volume of the boiler shell, and reducing the combustion efficiency, so as to reduce the excessive The effect of resistance loss along the process and operating energy consumption, reduction of boiler weight, and shortening of processing length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

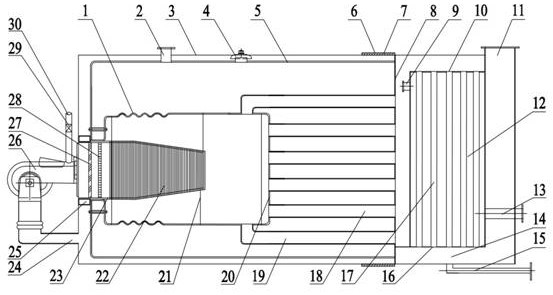

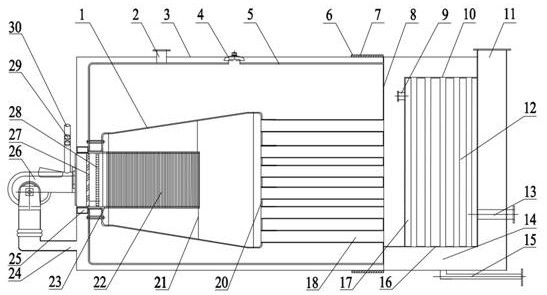

[0055] The present invention will be described in further detail below in conjunction with the accompanying drawings.

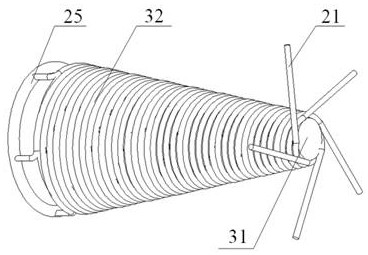

[0056] refer to figure 1 and figure 2 , a fully premixed water-cooled combustion shell-type gas boiler, including a furnace 1 and a burner, the burner includes a water-cooled combustion head 22 and a premixer 27, and the water-cooled combustion head 22 is coaxially arranged in the furnace 1, Furnace 1 is arranged in pot shell 5, outer shell plate 3 is arranged on the outside of pot shell 5, the rear end of furnace 1 is connected with smoke pipe, and the inner rear end of shell plate 3 is arranged in turn along flue gas flow direction with flue gas condenser 12 and flue gas. Gas outlet 11; a premixer 27 is arranged at the entrance of the water-cooled combustion head 22; the water-cooled combustion head 22 adopts several spiral water-cooled tubes 32 coiled side by side, and gaps are arranged between adjacent spiral water-cooled tubes 32, and the spiral water-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com