A kind of negative electrode material of sodium ion battery and its preparation method and application

A sodium-ion battery and negative electrode material technology, which is applied in the direction of battery electrodes, negative electrodes, secondary batteries, etc., can solve the problems of limiting the application of negative electrode materials, poor conductivity, volume expansion, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] The present invention also provides the preparation method of the negative electrode material of the sodium ion battery according to the above technical solution, comprising the following steps:

[0039] Mix the tin source, molybdenum source, concentrated hydrochloric acid, thioglycolic acid, urea and water to obtain a mixed solution;

[0040] The sponge carbon is placed in the mixed solution, and hydrothermal reaction and sintering are performed in sequence to obtain a negative electrode material for a sodium ion battery.

[0041] In the present invention, unless otherwise specified, all raw materials are commercially available products well known to those skilled in the art.

[0042] In the present invention, a tin source, a molybdenum source, concentrated hydrochloric acid, thioglycolic acid, urea and water are mixed to obtain a mixed solution; in the present invention, the tin source is preferably stannous chloride, and the stannous chloride is preferably dihydrate ...

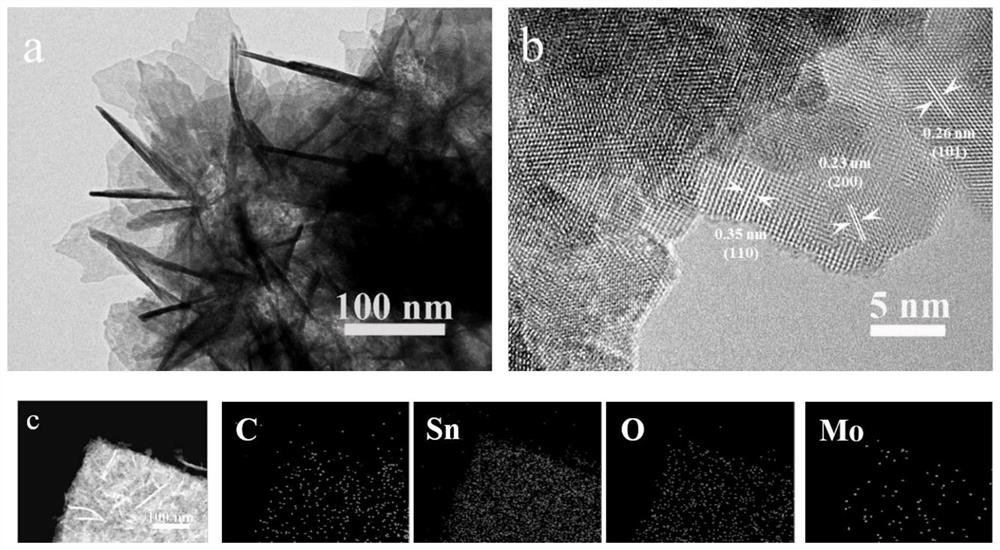

Embodiment 1

[0064] Under stirring conditions, 1 g of urea, 20 μL of thioglycolic acid and 1 mL of 37 wt% concentrated hydrochloric acid were added to 80 mL of water in sequence until uniform, and then 0.238 g (0.00105 mol) of stannous chloride dihydrate and 0.022 g (0.00009 mol) of stannous chloride were added in sequence. ) sodium molybdate dihydrate to obtain mixed solution;

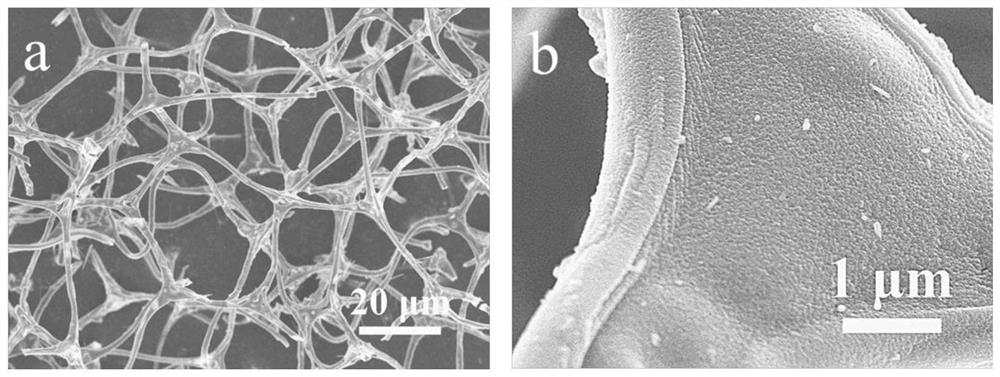

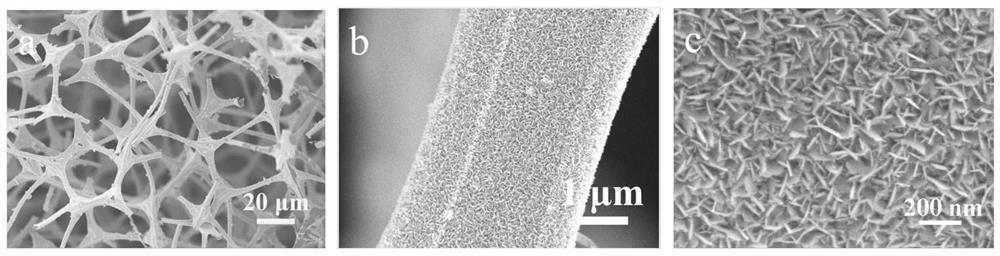

[0065] Under ultrasonic conditions, the melamine sponge was cleaned with ethanol for 15 min, and then dried in vacuum; in an argon atmosphere, the temperature was raised to 800 °C at a heating rate of 5 °C / min, followed by high-temperature carbonization for 1 h, and then cooled; the cooled product was After hydrophilic treatment in plasma gas, soaked in 1 mol / L HCl solution, soaked at 35 °C for 24 h, and dried to obtain sponge carbon;

[0066] The sponge carbon (5.6g) of size 4cm*1cm*0.5cm was placed in 80mL of mixed solution, and after hydrothermal reaction (120°C, 12h), water cooling and filtration were performe...

Embodiment 2

[0072] Under stirring conditions, 1 g of urea, 20 μL of thioglycolic acid and 1 mL of 37 wt% concentrated hydrochloric acid were sequentially added to 80 mL of water until uniform, and then 0.357 g (0.00158 mol) of stannous chloride dihydrate and 0.022 g (0.00009 mol of ) sodium molybdate dihydrate to obtain mixed solution;

[0073] Under ultrasonic conditions, the melamine sponge was cleaned with ethanol for 15 min, and then dried in vacuum; in an argon atmosphere, the temperature was raised to 800 °C at a heating rate of 5 °C / min, followed by high-temperature carbonization for 1 h, and then cooled; the cooled product was After hydrophilic treatment in plasma gas, soaked in 1 mol / L HCl solution, soaked at 35 °C for 24 h, and dried to obtain sponge carbon;

[0074] The sponge carbon (5.2g) of size 4cm*1cm*0.5cm was placed in 80mL of mixed solution, and after hydrothermal reaction (120°C, 12h), water cooling and filtration were performed in turn, and deionized water and ethanol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com