Holmium-based up-conversion nano material and preparation method thereof

A nanomaterial and nanoparticle technology, which is applied to the field of small-sized holmium-based up-conversion nanomaterials and their preparation, can solve problems such as fluorescence quenching, and achieve the effects of low equipment cost, simple preparation process and short preparation period.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

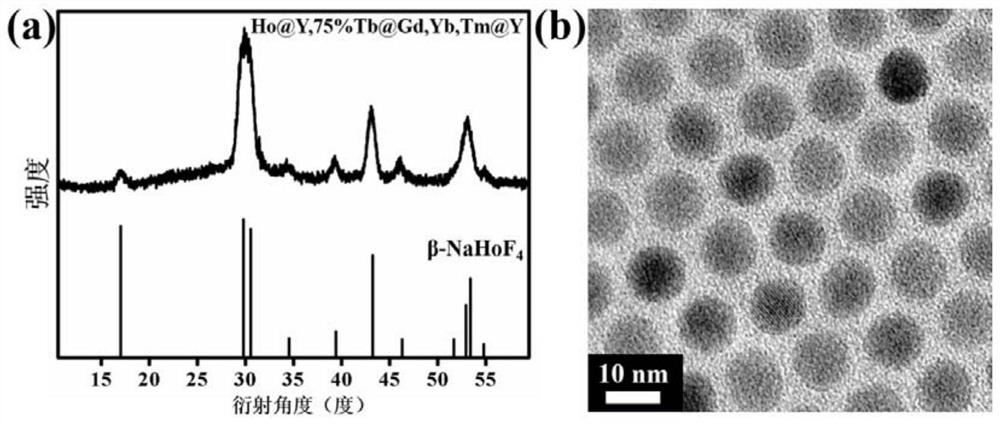

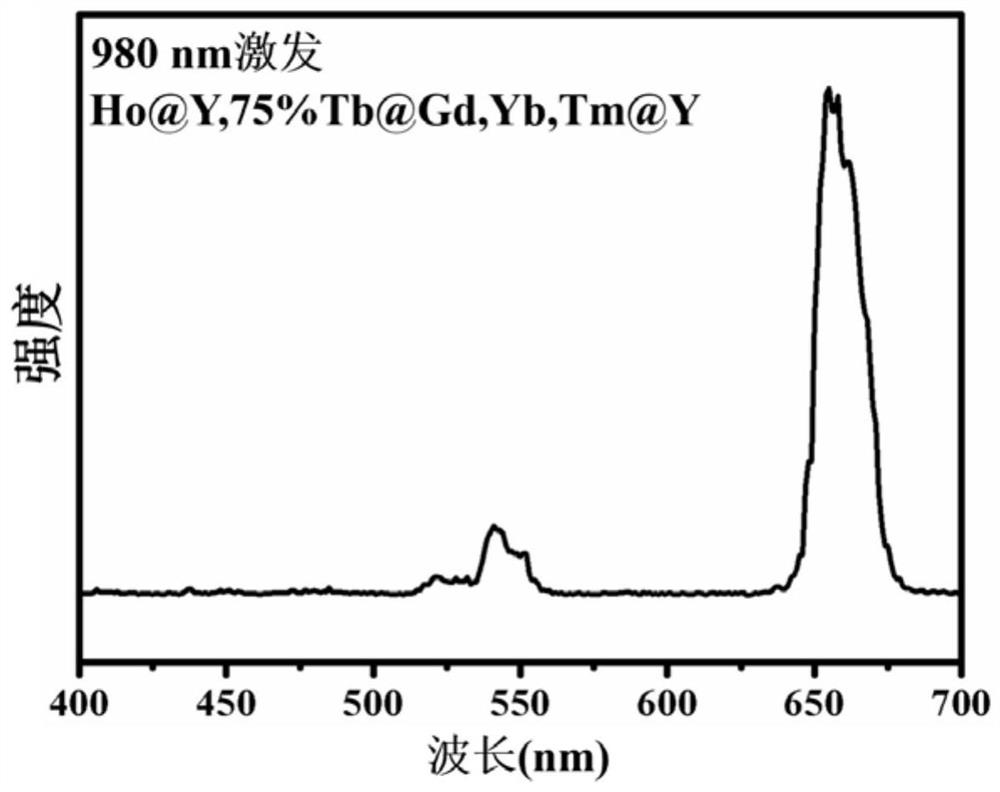

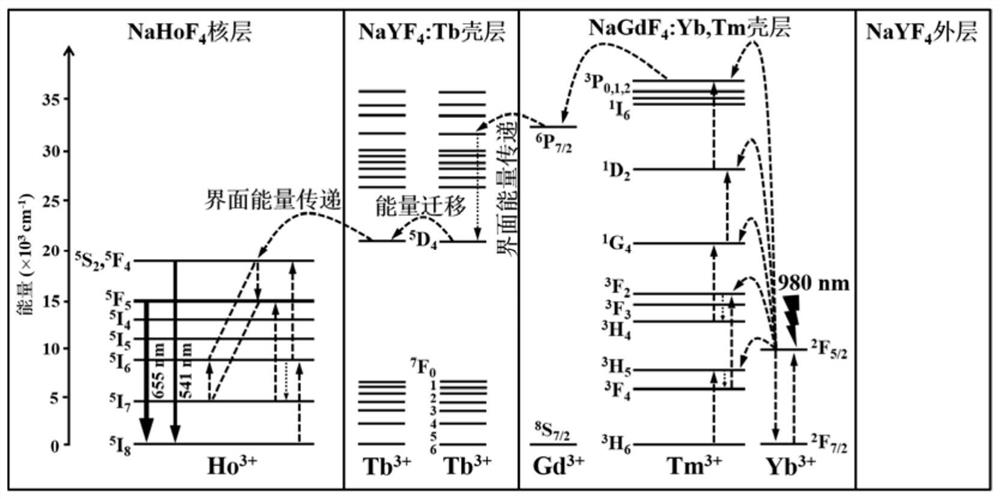

[0083] This embodiment provides a NaHoF 4 @NaYF 4 :75%Tb@NaGdF 4 :49%Yb,1%Tm@NaYF 4 Preparation methods of upconversion nanomaterials.

[0084] (1)NaHoF 4 Nuclear layer preparation: put 15mL oleic acid and 20mL octadecene into a 100mL three-necked flask, mix and stir evenly. Then add 1mL concentration of 1mol L -1 Holmium chloride solution, mix and stir evenly, then raise the temperature to 105°C and keep it for 40min to remove water. Then the temperature was raised to 150°C and kept for 40 minutes to form a rare earth-oleic acid chelate. Then the temperature was naturally cooled to room temperature, 0.1 g of sodium hydroxide (2.5 mmol) and 0.148 g of ammonium fluoride (4 mmol) in methanol (10 mL in total) were added to the above mixture and stirred, then the temperature was raised to 90 ° C and kept for 1 h , to remove excess methanol. Then, under the protection of argon, the temperature was raised to 280° C. for 1 h. Finally, the cloudy liquid after the reaction was...

Embodiment 2

[0089] This embodiment provides a NaHoF 4 @NaYF 4 :70%Tb@NaGdF 4 :46%Yb,0.75%Tm@NaYF 4 Preparation methods of upconversion nanomaterials.

[0090] (1)NaHoF 4 Nuclear layer preparation: put 14mL oleic acid and 20mL octadecene into a 100mL three-necked flask, mix and stir evenly. Then add 1mL concentration of 1mol L -1 Holmium chloride solution, mix and stir evenly, then raise the temperature to 100°C and keep it for 40min to remove water. Then the temperature was raised to 140° C. and kept for 40 minutes to generate a rare earth-oleic acid chelate. Then the temperature was naturally cooled to room temperature, 0.1 g of sodium hydroxide (2.5 mmol) and 0.148 g of ammonium fluoride (4 mmol) in methanol (10 mL in total) were added to the above mixture and stirred, then the temperature was raised to 85 ° C and kept for 1 h , to remove excess methanol. Then, under the protection of argon, the temperature was raised to 275° C. for 1 h. Finally, the cloudy solution after the r...

Embodiment 3

[0095] This embodiment provides a NaHoF 4 @NaYF 4 :80%Tb@NaGdF 4 :52%Yb,1.25%Tm@NaYF 4 Preparation methods of upconversion nanomaterials.

[0096] (1)NaHoF 4 Nuclear layer preparation: put 16mL oleic acid and 20mL octadecene into a 100mL three-necked flask, mix and stir evenly. Then add 1mL concentration of 1mol L -1 Holmium chloride solution, mix and stir evenly, then raise the temperature to 110°C and keep it for 40min to remove water. Then the temperature was raised to 160° C. and kept for 40 minutes to form a rare earth-oleic acid chelate. Then the temperature was naturally cooled to room temperature, 0.1 g of sodium hydroxide (2.5 mmol) and 0.148 g of ammonium fluoride (4 mmol) in methanol (10 mL in total) were added to the above mixture and stirred, then the temperature was raised to 95 ° C and kept for 1 h , to remove excess methanol. Then, under the protection of argon, the temperature was raised to 285° C. for 1 h. Finally, the cloudy solution after the react...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com