Invar alloy corrosive liquid and application thereof

A technology of Invar alloy and corrosive liquid, applied in Invar corrosive liquid and its application field, can solve the problems of difficult control of corrosion process, failure of corrosion liquid, and difficulty in corrosion work, etc., and achieves good surface quality of samples and corrosion efficiency. The effect of improving, good corrosion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

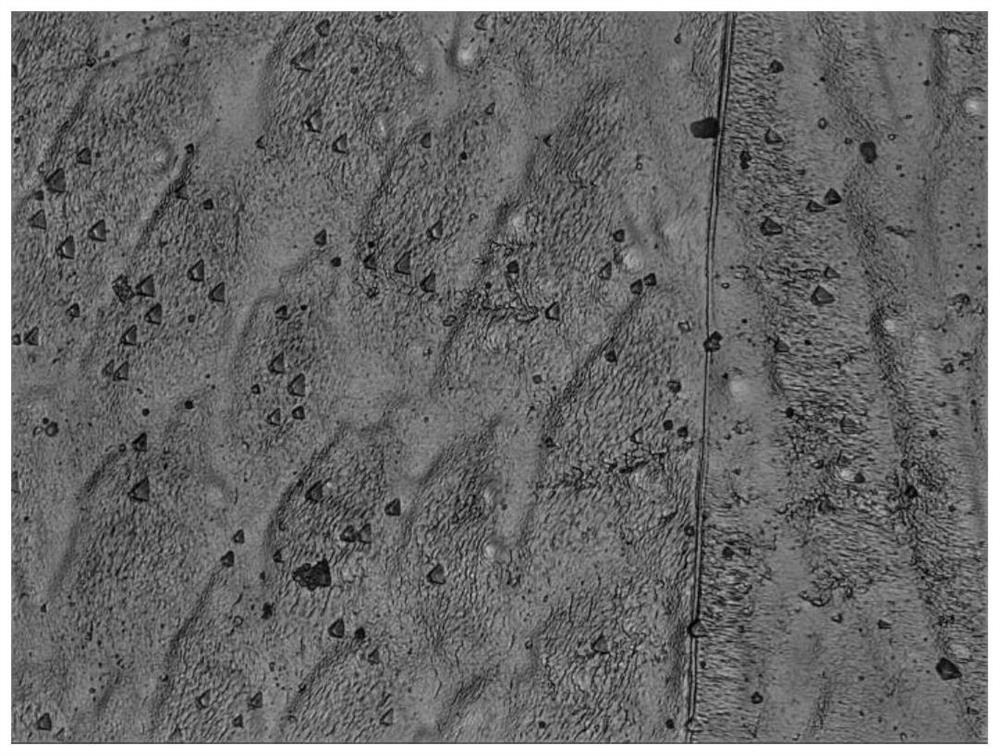

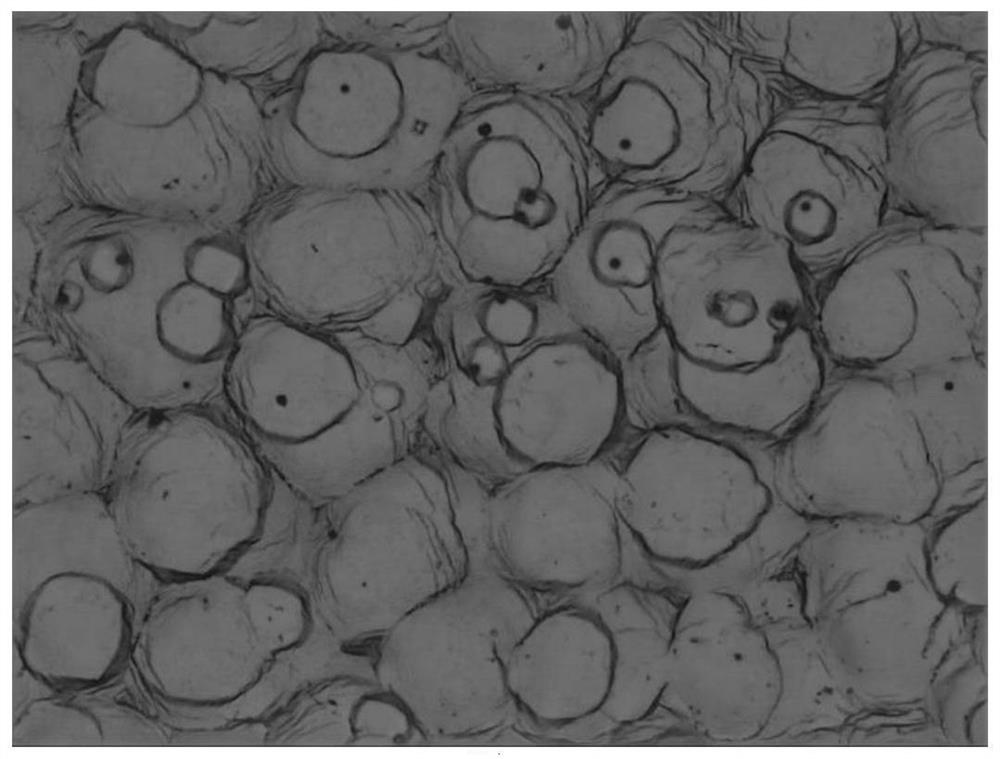

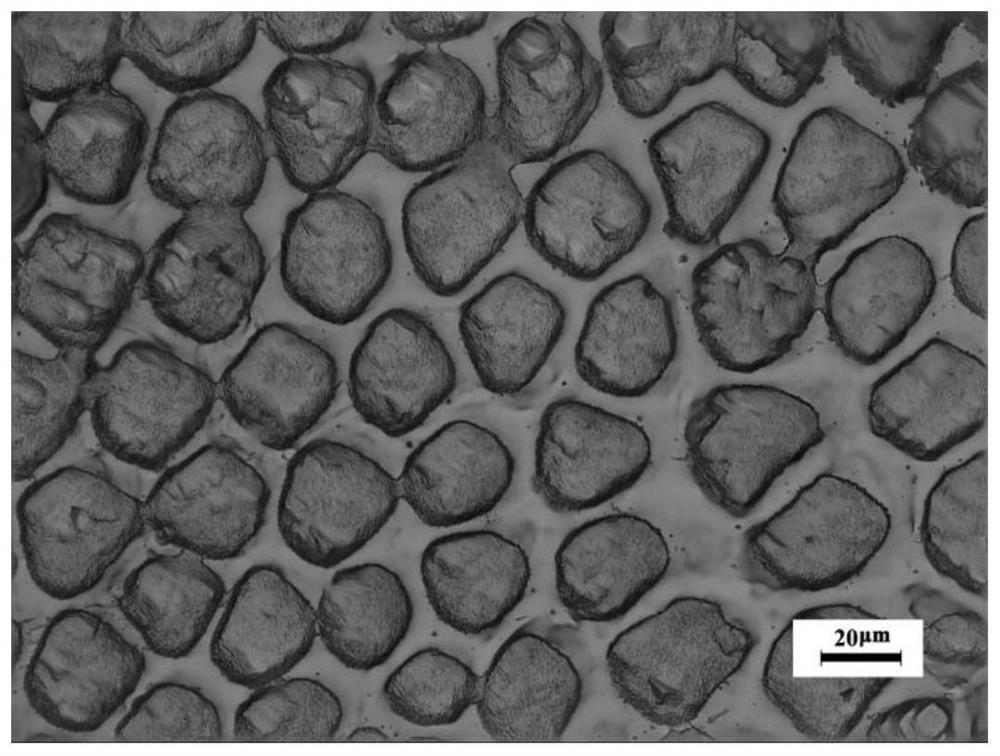

[0039] Pour concentrated hydrochloric acid (10% mass ratio - refers to the proportion of the total mass of the corrosion solution, the same ratio below) and glycerin (10% mass ratio) with a mass concentration of 36%-38% into water (35% mass ratio) in sequence , finally ferric chloride (40% mass ratio), cupric chloride (5% mass ratio) are put into above-mentioned solution again, fully stir 2min again after mixing, to guarantee that ferric chloride and cupric chloride melt completely. Goggles and protective gloves must be worn during the configuration corrosion process. The prepared corrosive solution is left to stand for corrosion; take the Invar alloy sample and grind it with 400#, 600#, 1000#, 1200#, 1500#, 2000#, 2500# sandpaper. Grind off the grinding marks of the previous sandpaper and finish. After the grinding is finished, carry out rough polishing and fine polishing (polishing is completed by diamond abrasive paste and navy cloth polishing cloth, wherein the abrasive pa...

Embodiment 2

[0042]Concentrated hydrochloric acid (10% mass ratio) and glycerol (10% mass ratio) are poured into water (35% mass ratio) successively by mass concentration, and finally ferric chloride (40% mass ratio ), cupric chloride (5% mass ratio) is put into above-mentioned solution, fully stir 2min again after mixing, to guarantee ferric chloride and cupric chloride melt completely. Goggles and protective gloves must be worn during the configuration corrosion process. The prepared corrosion solution was left to stand for 3 days for corrosion use; take the Invar alloy sample, and then grind it with 400#, 600#, 1000#, 1200#, 1500#, 2000#, 2500# sandpaper, and grind each time Grind off the grinding marks of the previous sandpaper before finishing. After the grinding is finished, carry out rough polishing and fine polishing, and throw it until there is no scratch on the surface of the sample (the roughness of the sample is Ra=0.63~0.01 micron), and the polishing is completed. The final s...

Embodiment 3

[0045] Concentrated hydrochloric acid (10% mass ratio) and glycerol (10% mass ratio) with a mass concentration of 36%-38% are poured into water in turn, and finally ferric chloride (40% mass ratio), copper chloride (5% mass ratio) into the above-mentioned solution, and then fully stir for 2 minutes after mixing to ensure that the ferric chloride and copper chloride are completely melted. Goggles and protective gloves must be worn during the configuration corrosion process. The prepared corrosive solution was left to stand for 7 days for corrosion use; the Invar alloy sample was taken, and it was ground with 400#, 600#, 1000#, 1200#, 1500#, 2000#, 2500# sandpaper, and each grinding Grind off the grinding marks of the previous sandpaper before finishing. After the grinding is finished, carry out rough polishing and fine polishing, and throw it until there is no scratch on the surface of the sample (the roughness of the sample is Ra=0.63~0.01 micron), and the polishing is complet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com