Rapid detection method for cyanide in sorghum

A detection method and cyanide technology, applied in measuring devices, instruments, scientific instruments, etc., can solve the problems of long time, large detection error, cumbersome pretreatment, etc., and achieve the effect of high accuracy, high sensitivity, and difficult judgment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

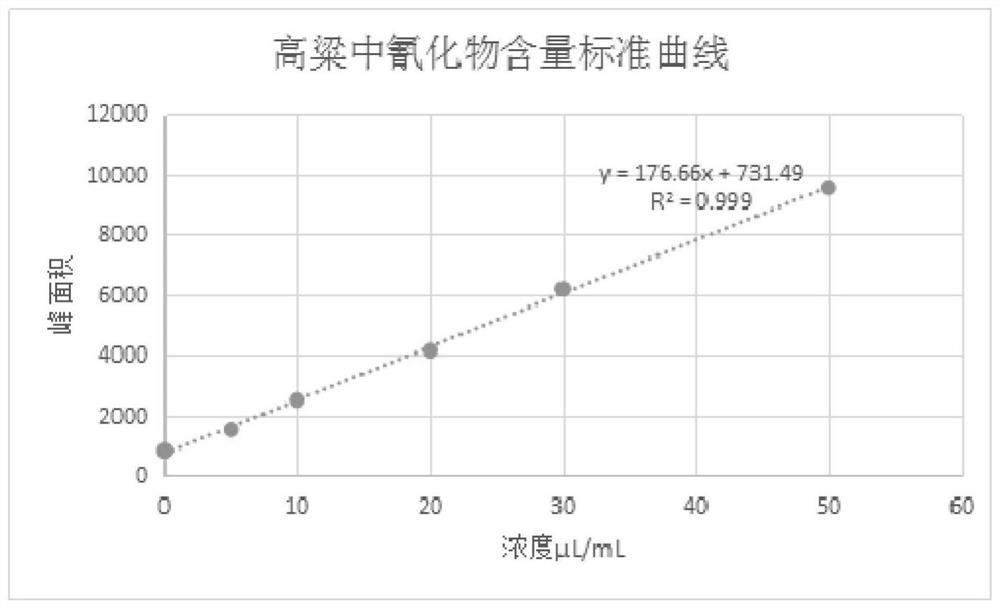

[0045] Standard curve and linear relationship

[0046] The method provided in this embodiment includes the following steps:

[0047] (1) Preparation of the solution:

[0048] Cyanide ion standard solution: 1000μg / mL (mother solution);

[0049] Cyanide standard intermediate solution 1μg / mL (prepared and used now): Take 100μL cyanide standard solution and dilute to 100mL with ultrapure water;

[0050] 0.5mol / L phosphate buffer solution: 3.4g anhydrous potassium dihydrogen phosphate and 3.55g anhydrous disodium hydrogen phosphate, dissolved in ultrapure water, and dilute to 100mL;

[0051] 10g / L Chloramine T solution (preparation for current use): Dissolve 1g Chloramine T in ultrapure water and dilute to 100mL;

[0052] (2) Sample pretreatment, the specific process is as follows: sorghum is pulverized into powder with a high-speed universal grinder, and it feels grainy to the touch, and the particle diameter is about 1mm. 10mL of pure water, put the headspace bottle into the ...

Embodiment 2

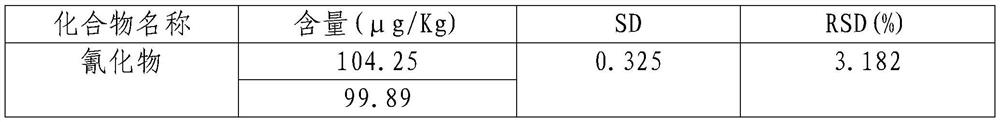

[0063] Embodiment 2 Precision experiment

[0064] The method provided in this embodiment includes the following steps:

[0065] Take 1 g of the same crushed sorghum sample, and perform three independent repeated measurements according to the steps in Example 1, and the RSD obtained is 3.182%, which is within the range of 5% required by the precision test standard, indicating that the method has high precision. The specific precision test results are shown in Table 1:

[0066] Table 1 Evaluation data of detection method for cyanide content in sorghum

[0067]

[0068]

Embodiment 3

[0069] Embodiment 3 recovery rate experiment

[0070] The method provided in this embodiment includes the following steps:

[0071] Add 10 μg / L, 20 μg / L, and 30 μg / L three different concentrations of cyanide standard substances to the cyanide extract of the same sorghum sample, and measure it according to the steps described in Example 1, and each concentration is repeated under repeated conditions. The recovery rate was determined twice independently, and the recovery rate was in the range of 89.5-108.9, indicating that the performance of the method met the requirements. The specific recovery rate experimental results are shown in Table 2:

[0072] Table 2 Evaluation data of cyanide content detection method (cyanide concentration in headspace vial) in sorghum

[0073]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com