Structure for improving breakdown voltage of gallium nitride HEMT power device and preparation method thereof

A power device and breakdown voltage technology, applied in semiconductor/solid-state device manufacturing, semiconductor devices, circuits, etc., can solve the problems of reducing device frequency characteristics, gate leakage current, gate leakage, etc., to achieve high drain voltage, The effect of increasing breakdown voltage without degrading frequency characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

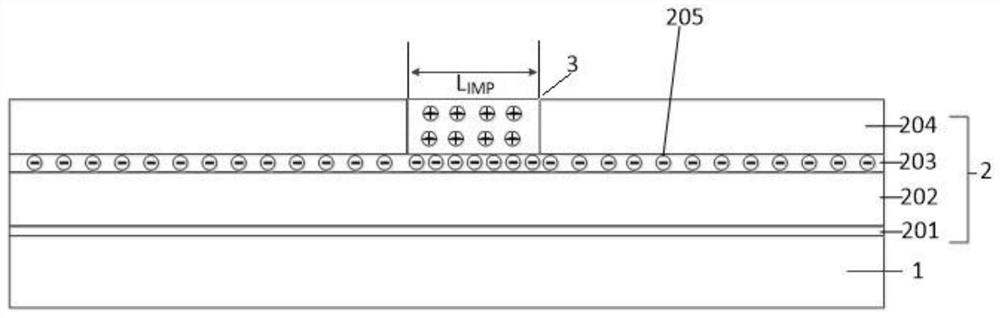

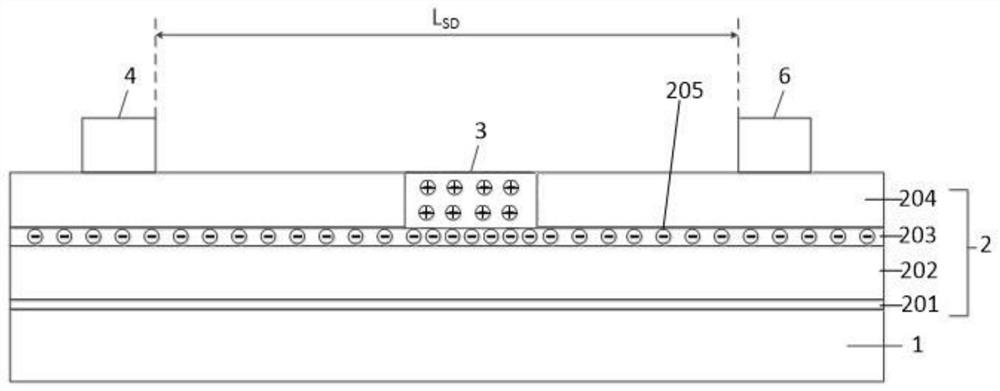

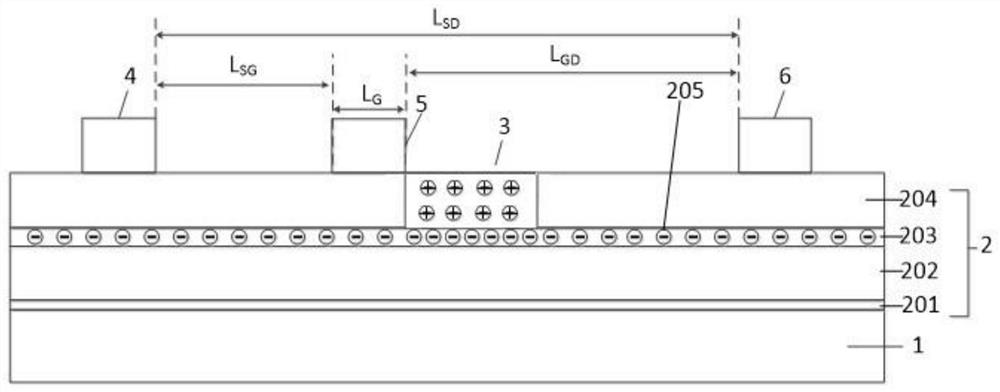

[0036] refer to Figure 1A-Figure 1C , a method for preparing a structure for improving the breakdown voltage of a gallium nitride HEMT power device in this embodiment, comprising the following steps:

[0037] Step 1: If Figure 1A As shown, silicon carbide is selected as the material of the substrate 1, and the nucleation layer 201, the first material layer 202, the channel layer 203 and the second material layer 204 are sequentially formed on the substrate 1 from bottom to top; wherein the nucleation layer 201 The material is aluminum nitride, the material of the first material layer 202 is gallium nitride, the material of the channel layer 203 is gallium nitride, and the material of the second material layer 204 is aluminum gallium nitride; The dopant region is shielded, and the implantation process is used to introduce arsenic ions into the second material layer 204 with a concentration of 5×10 13 cm -3 , form the ion-doped region 3, the width of the ion-doped region 3 ...

Embodiment 2

[0043] refer to Figure 2A-Figure 2C , a method for preparing a structure for improving the breakdown voltage of a gallium nitride HEMT power device in this embodiment, comprising the following steps:

[0044] Step 1: If Figure 2A As shown, silicon carbide is selected as the material of the substrate 1, and the nucleation layer 201, the first material layer 202, the channel layer 203, the third material layer 206 and the second material layer 204 are sequentially formed on the substrate 1 from bottom to top; The material of the nucleation layer 201 is aluminum nitride, the material of the first material layer 202 is gallium nitride, the material of the channel layer 203 is gallium nitride, the material of the third material layer 206 is indium gallium nitride, and the material of the second material layer 202 is gallium nitride. The material of layer 204 is aluminum gallium nitride; the non-ion-doped region is blocked by photolithography process, and fluorine ions are introd...

Embodiment 3

[0050] refer to Figure 3A-Figure 3C , a method for preparing a structure for improving the breakdown voltage of a gallium nitride HEMT power device in this embodiment, comprising the following steps:

[0051] Step 1: If Figure 3A As shown, silicon carbide is selected as the material of the substrate 1, and the nucleation layer 201, the first material layer 202, the channel layer 203, the second material layer 204, and the fourth material layer 207 are sequentially formed on the substrate 1 from bottom to top; The material of the nucleation layer 201 is aluminum nitride, the material of the first material layer 202 is gallium nitride, the material of the channel layer 203 is gallium nitride, the material of the second material layer 204 is aluminum gallium nitride, the fourth material The material of layer 207 is gallium nitride; the non-ion-doped region is blocked by photolithography process, and phosphorus ions are introduced into the second material layer 204 and the four...

PUM

| Property | Measurement | Unit |

|---|---|---|

| breakdown voltage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com